Product Introduction: The Global Choice for Flexible & Precise Mesh Solutions

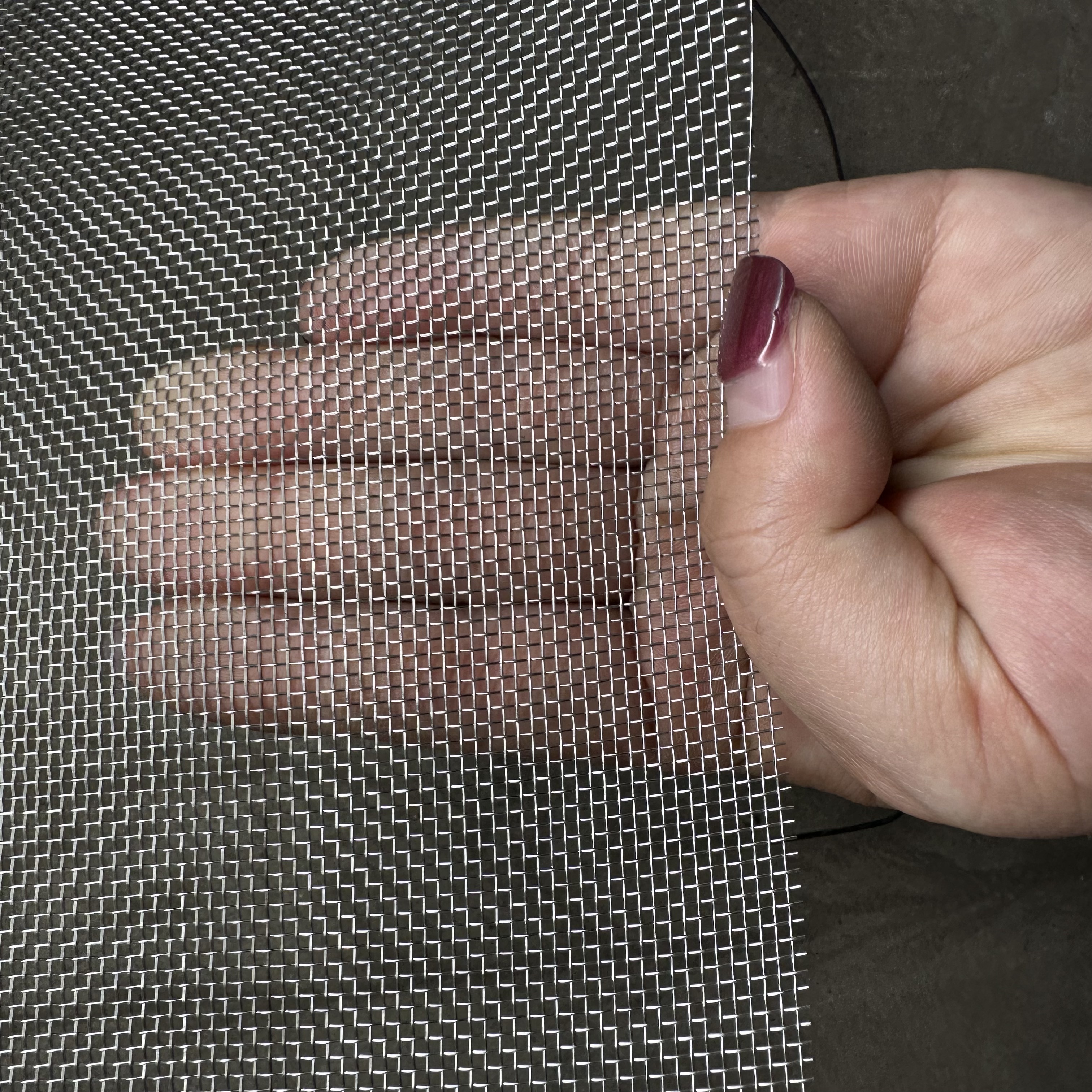

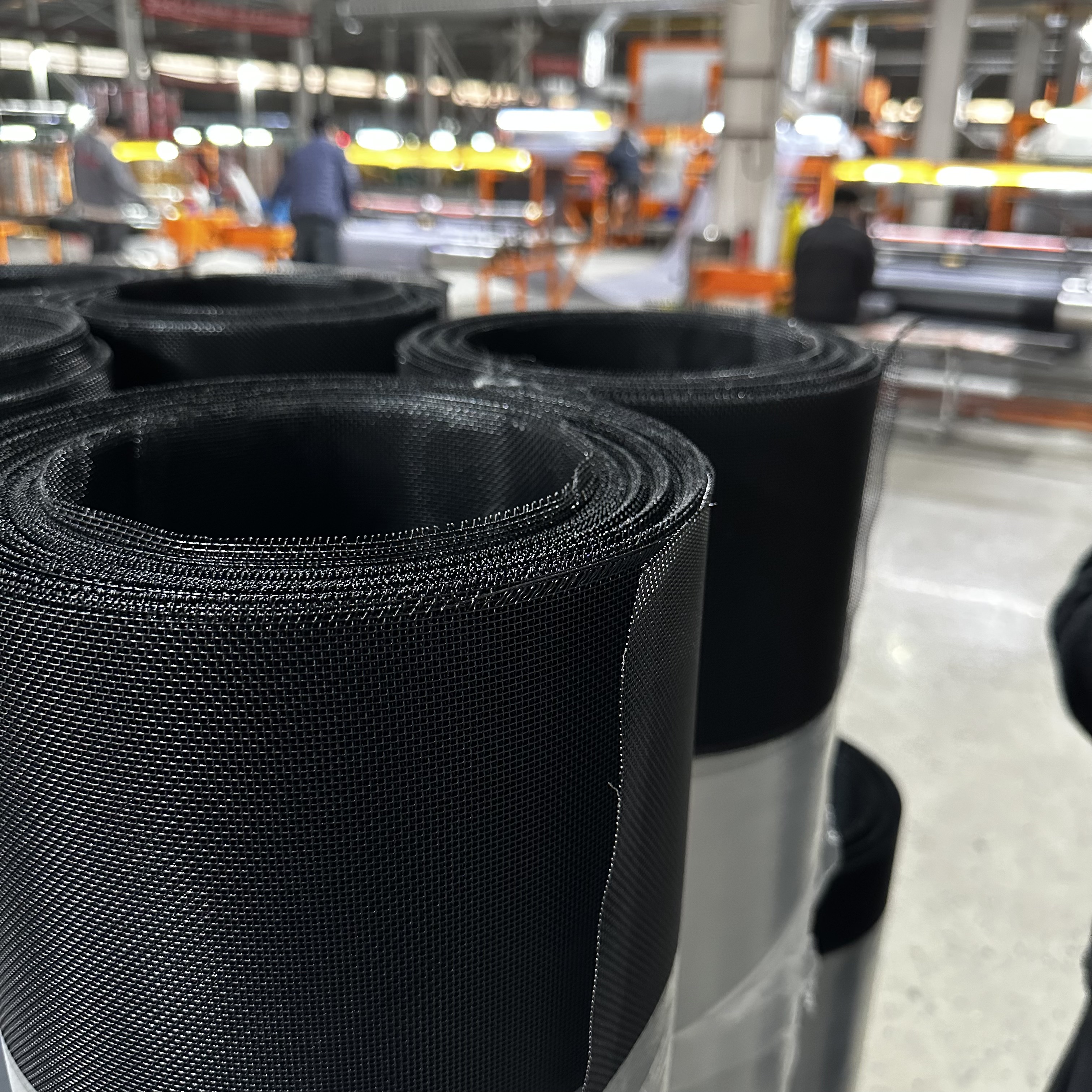

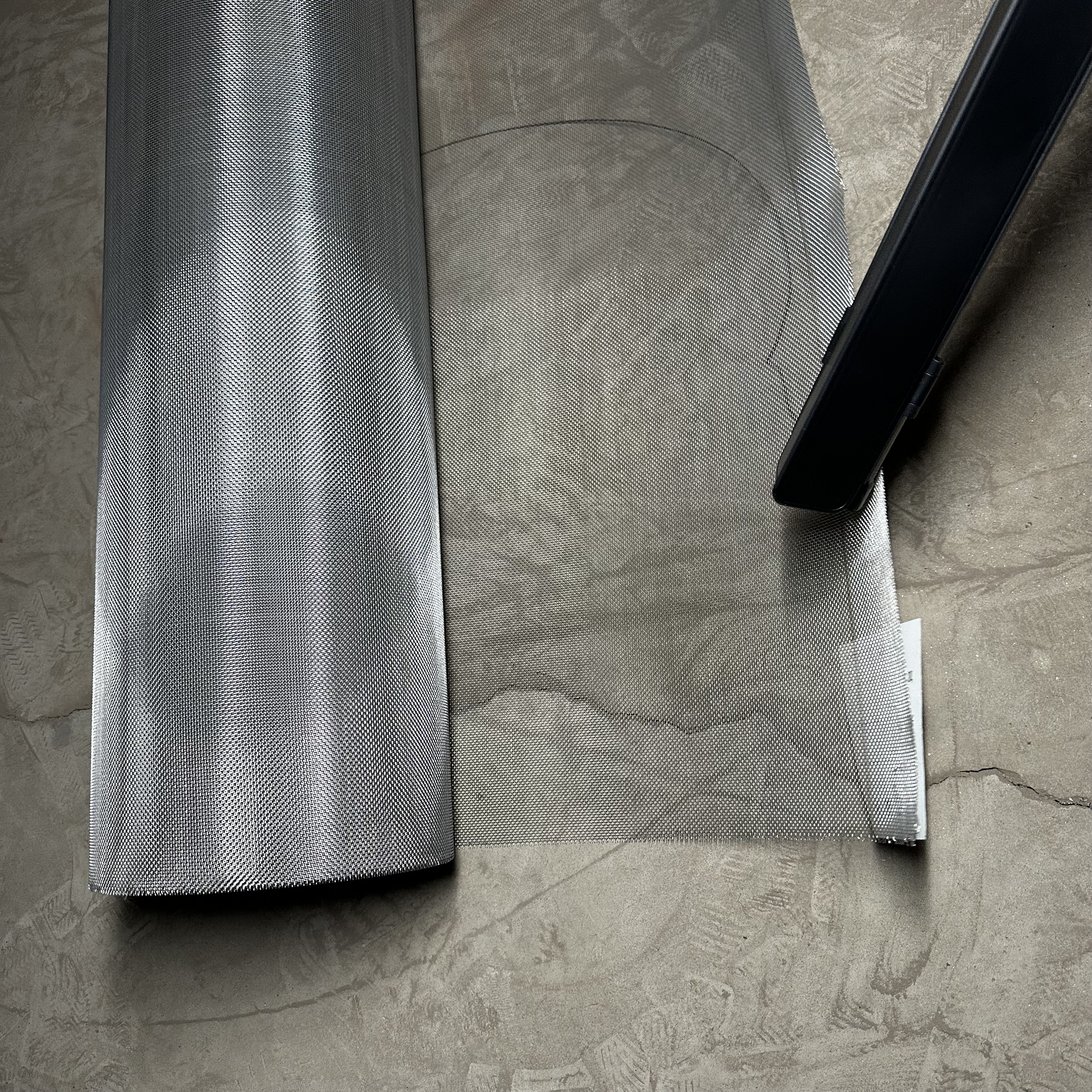

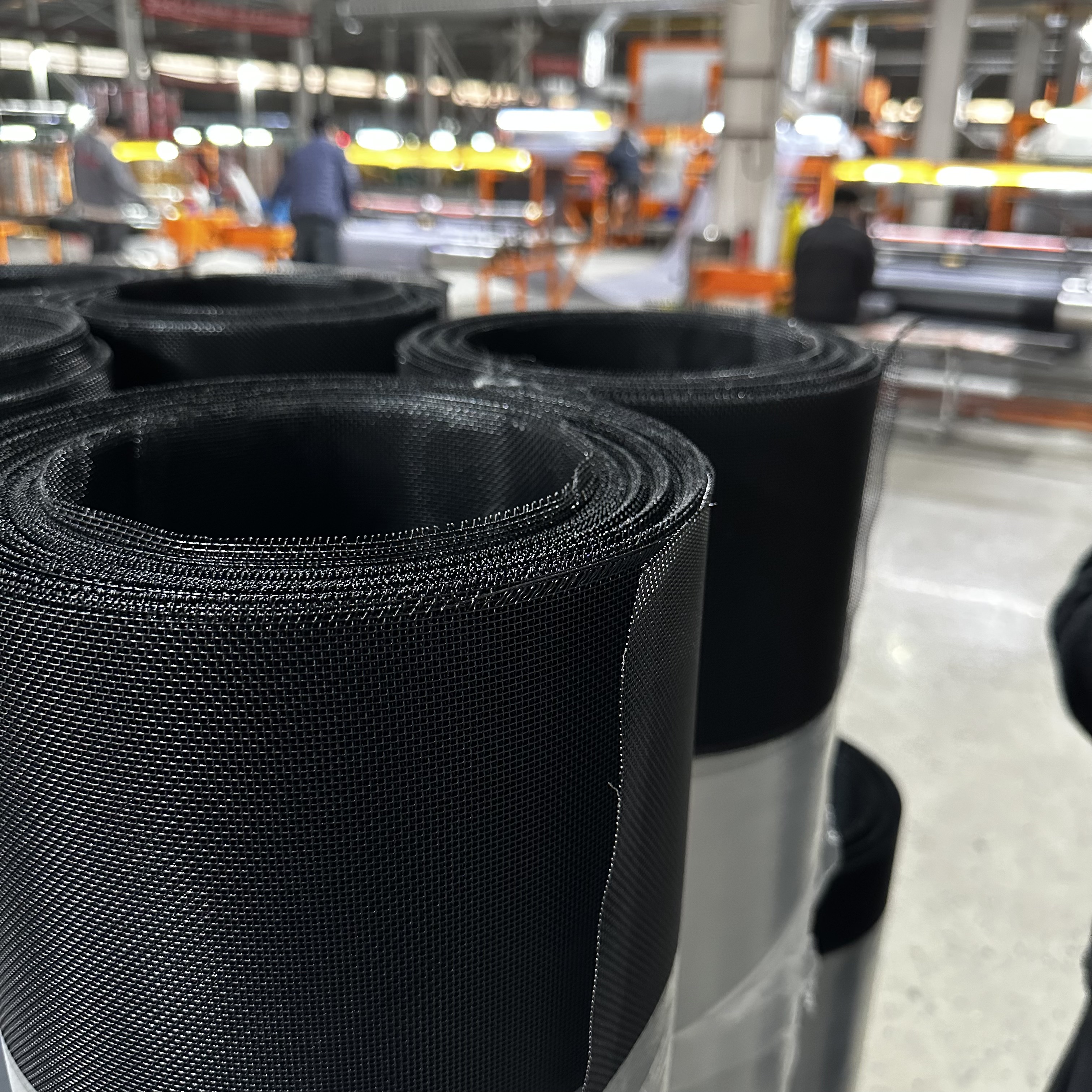

Woven Wire Mesh (Non-Crimped) is a high-performance, flexible metal mesh engineered through traditional interlacing of warp and weft wires—without pre-crimping or wave-shaped processing. Crafted from premium stainless steel (304/316), low-carbon steel, copper, or aluminum wire, this mesh delivers exceptional breathability, precise filtration, and lightweight adaptability. Compliant with international standards (ASTM A480, ISO 9001, EN 10204), it has become an indispensable choice across filtration, decoration, light-duty protection, and electronic manufacturing sectors in North America, Europe, Asia-Pacific, Africa, and the Middle East.

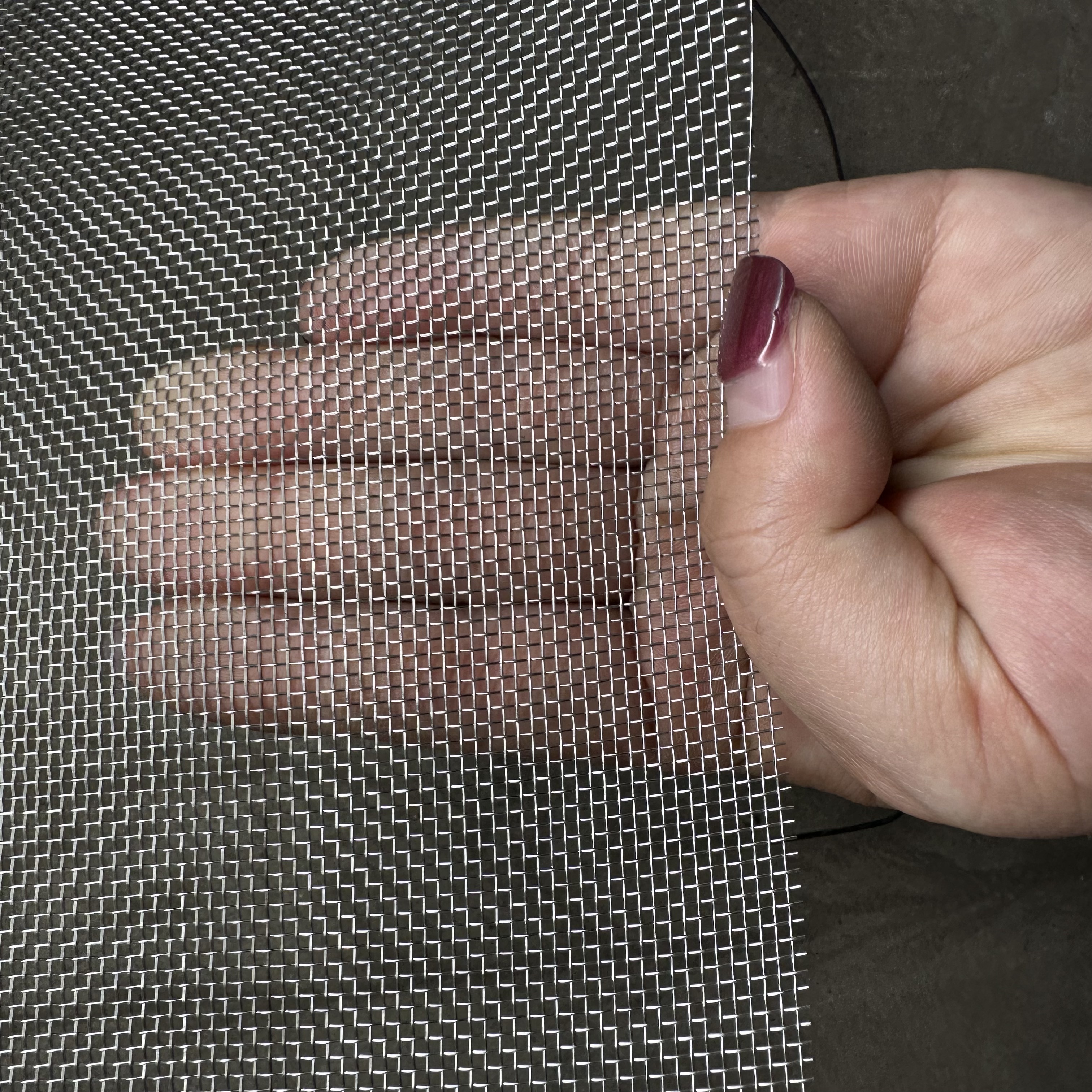

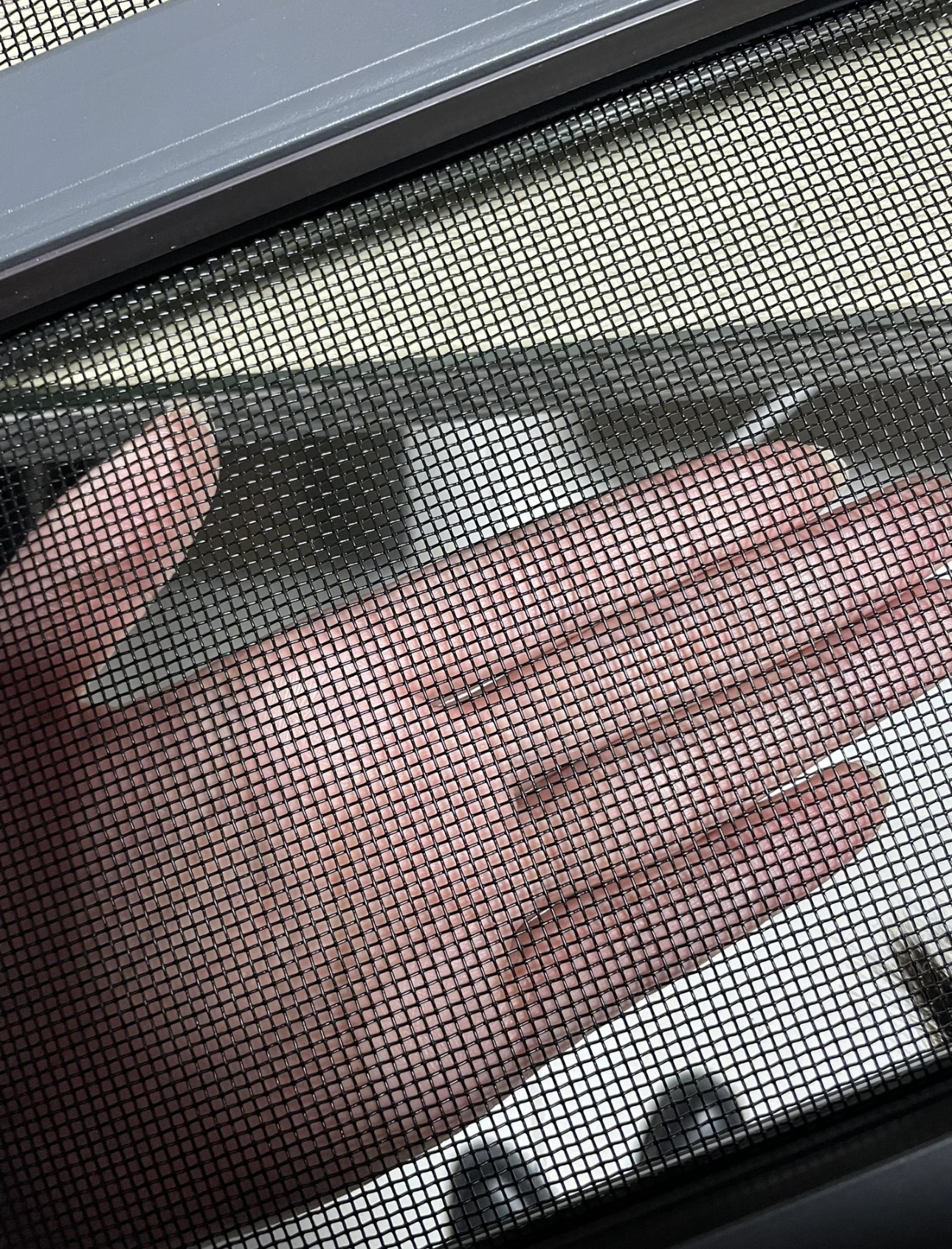

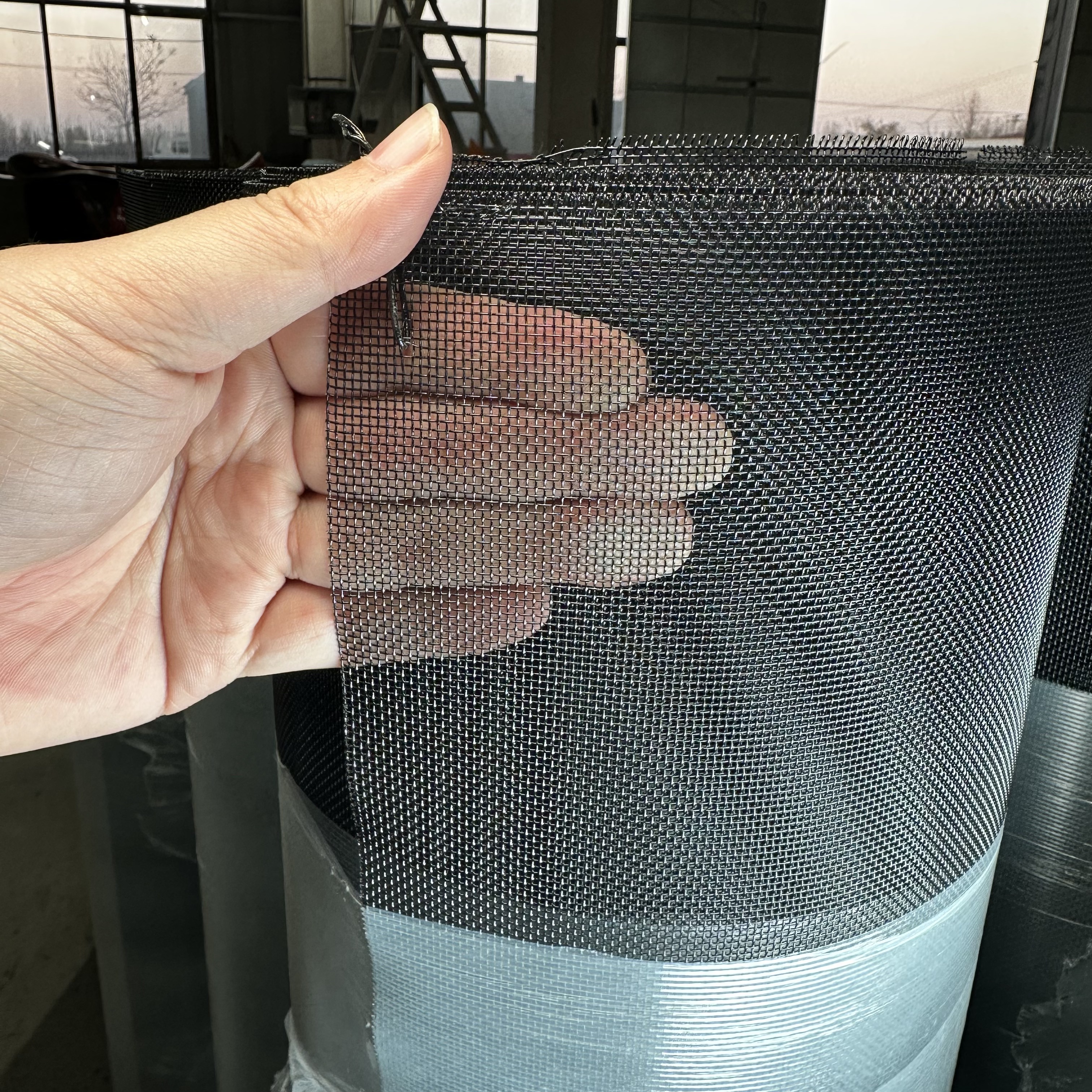

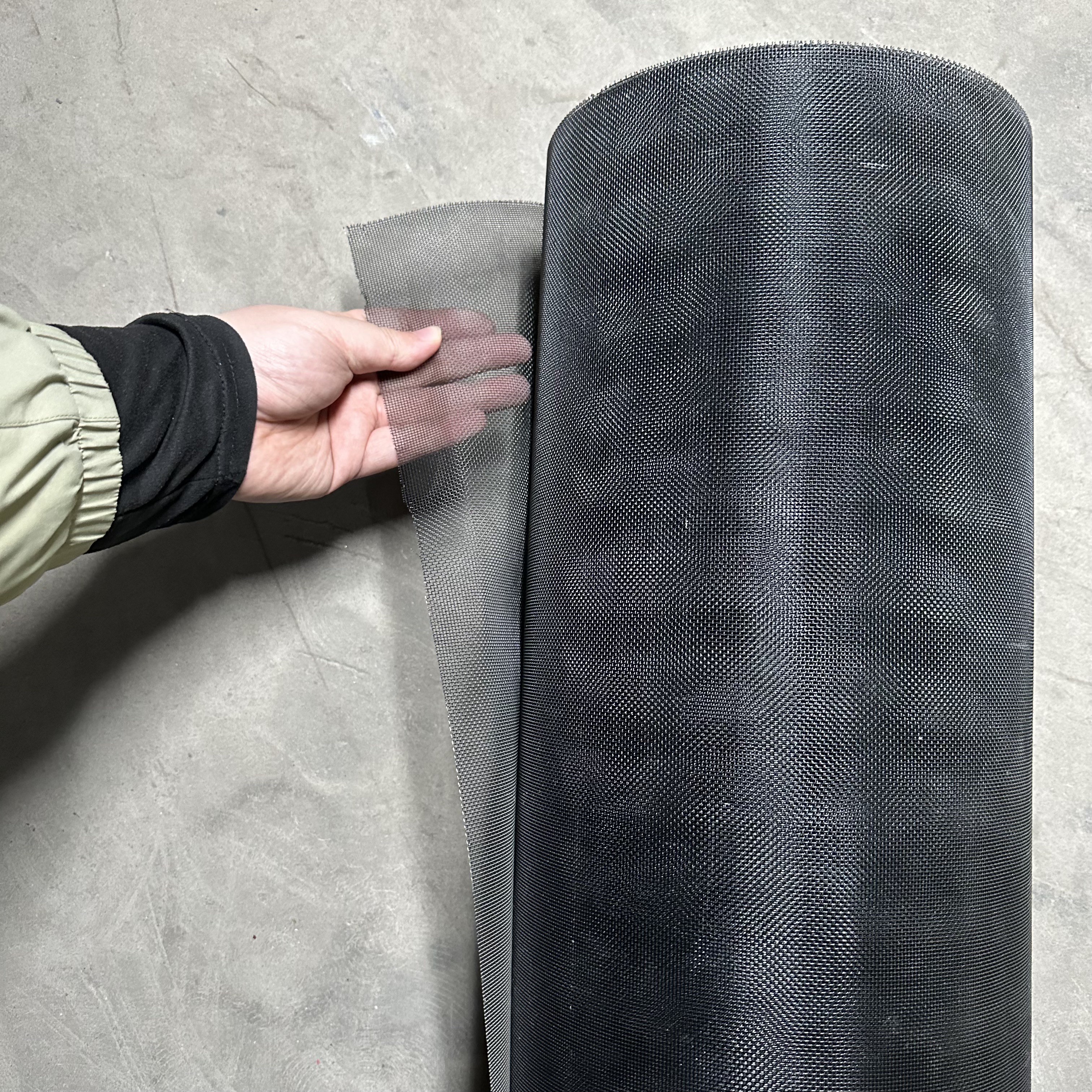

Unlike crimped mesh, its flat-wire woven structure ensures softness and flexibility, allowing easy cutting, bending, and shaping to fit complex surfaces. With customizable mesh sizes (from ultra-fine 0.05×0.05mm to 50×50mm), wire diameters, and materials, it balances precision, functionality, and cost-efficiency—making it the trusted solution for global buyers seeking flexible, lightweight mesh applications.

Core Features (Global Competitive Advantages)

1. Superior Flexibility & Adaptability

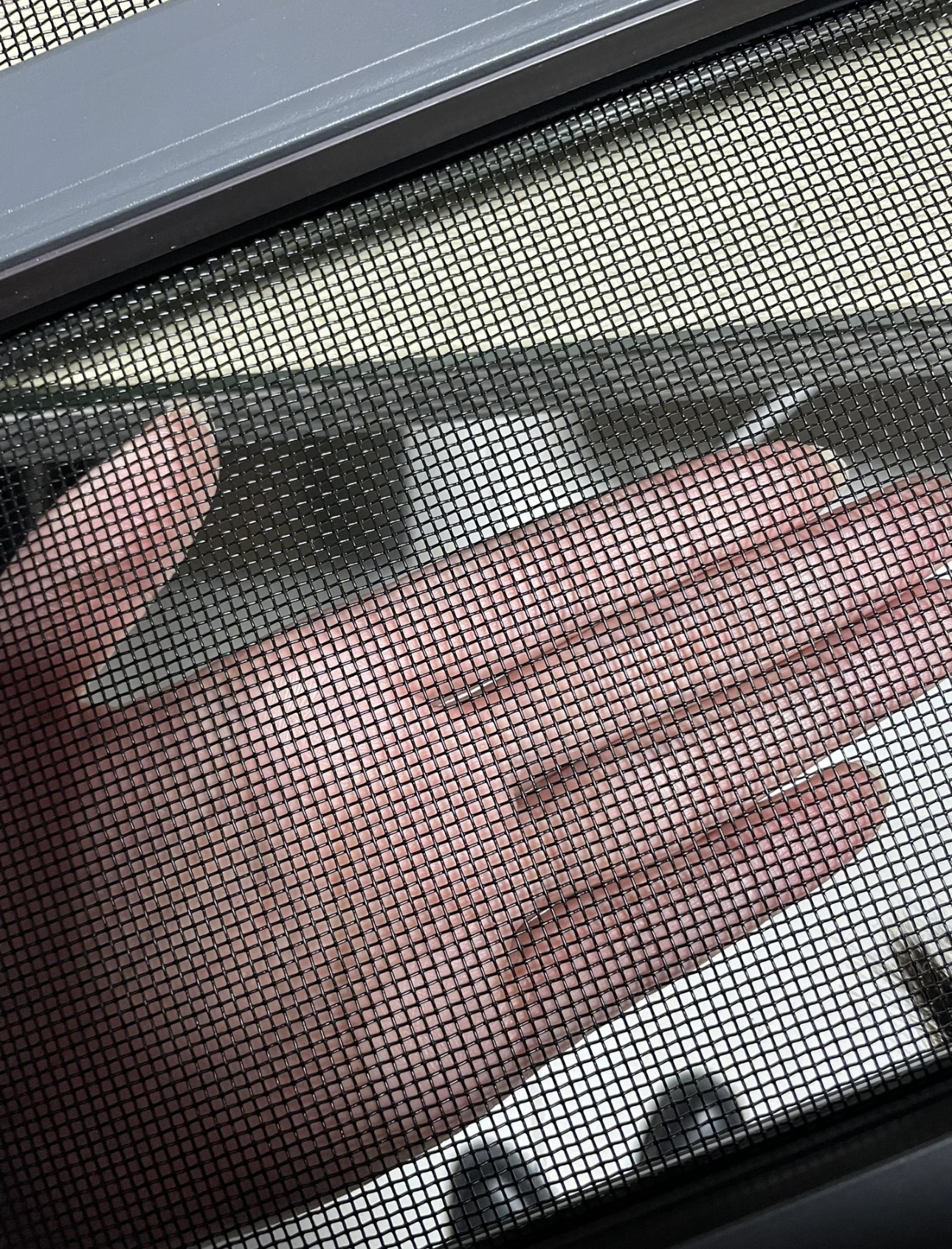

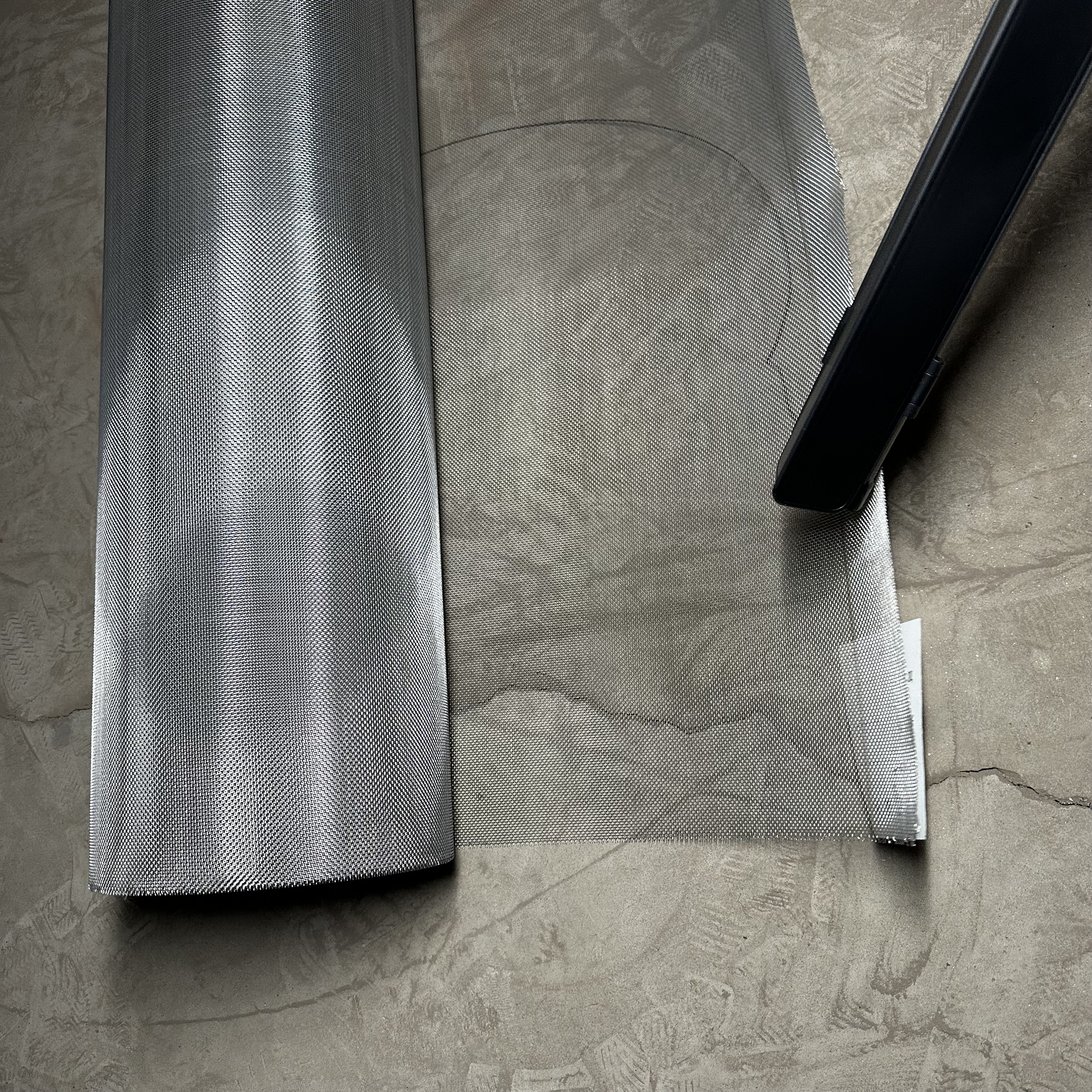

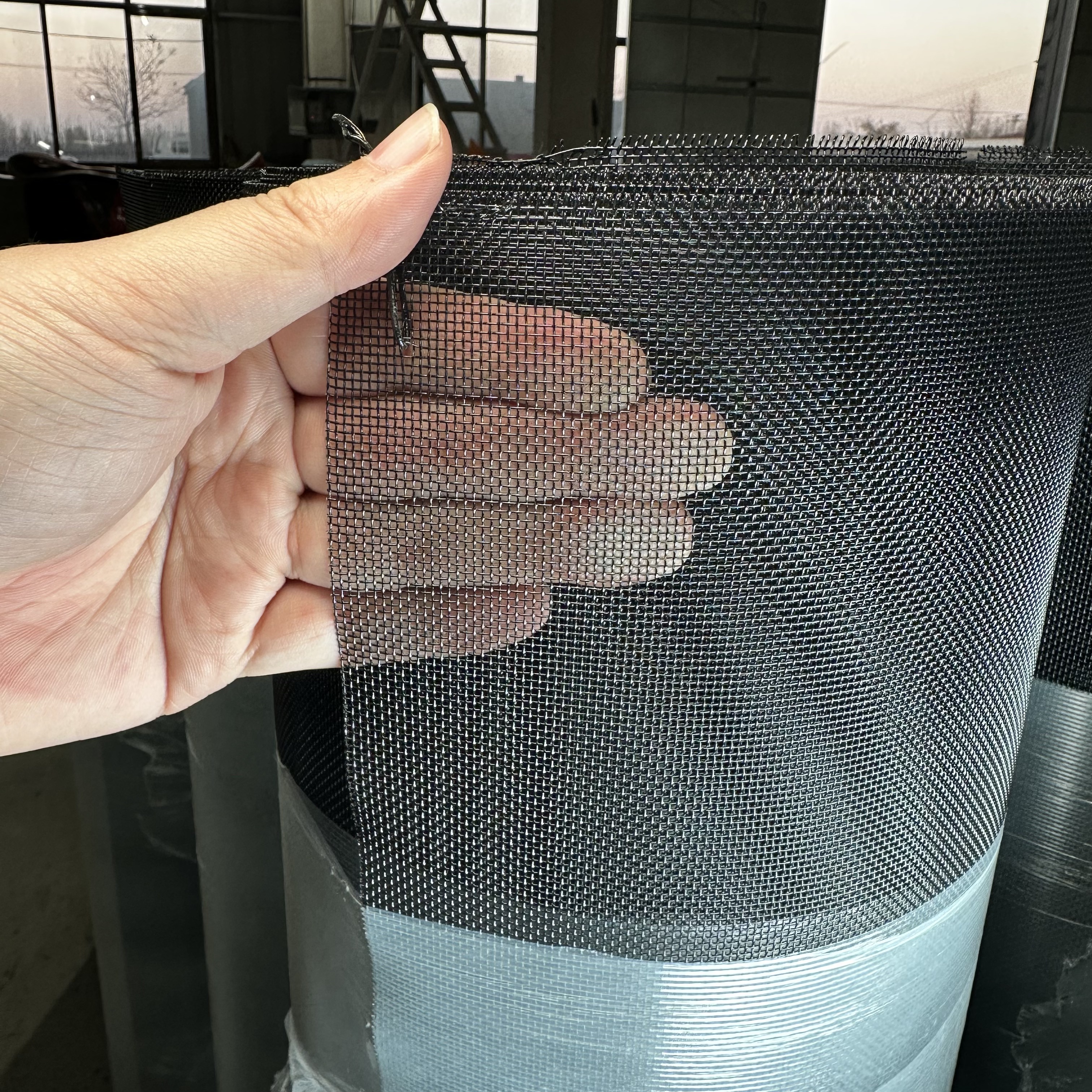

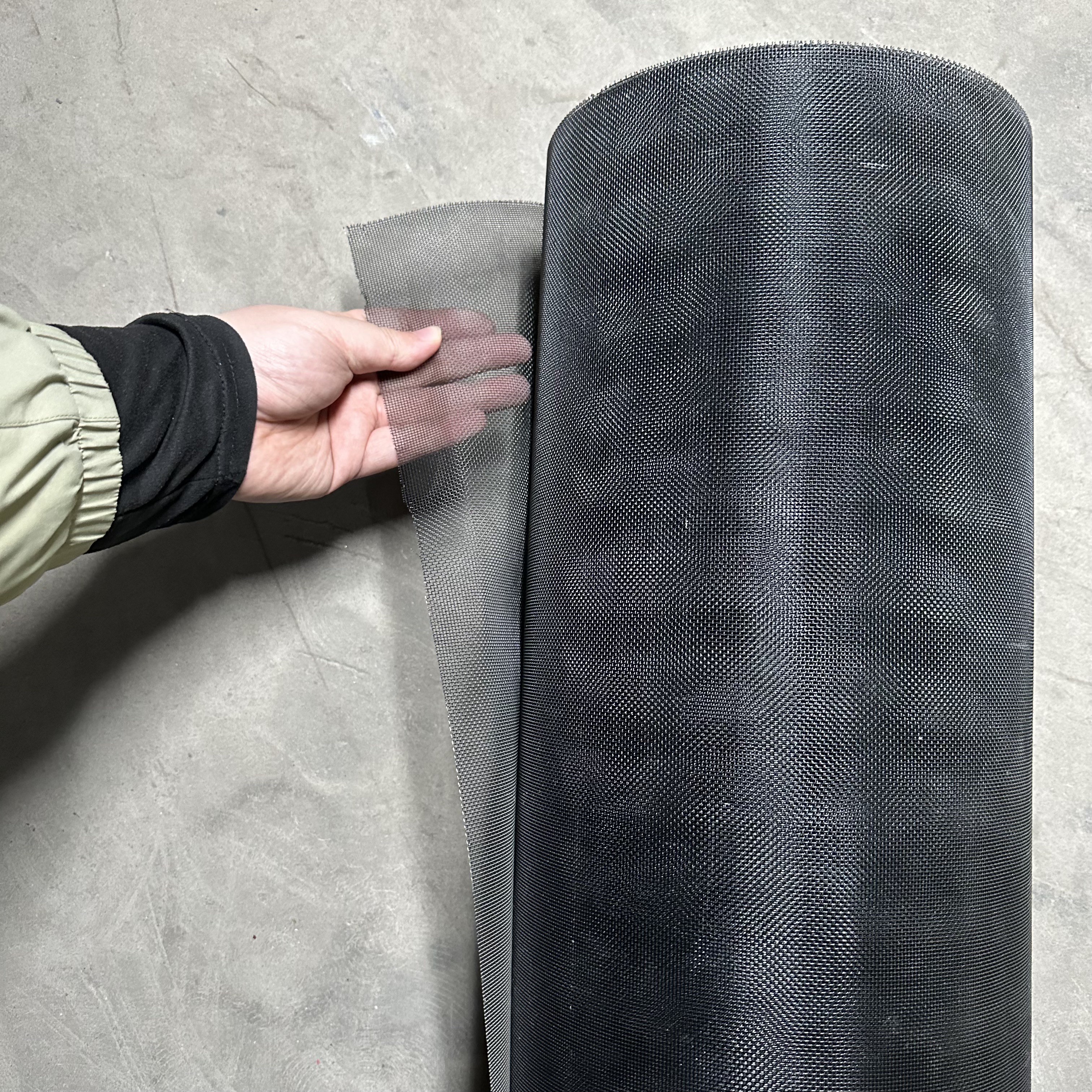

• Flat-Wire Woven Structure: Warp and weft wires are interlaced directly (plain weave, twill weave, Dutch weave) without pre-crimping, ensuring a soft, flexible mesh body. It can be easily cut into any shape, bent around curved surfaces, or rolled into coils for convenient transportation and installation.

• Lightweight & Space-Saving: Wire diameters range from 0.05mm to 2.0mm, with mesh weight as low as 0.5kg/㎡ (ultra-fine models), ideal for applications requiring minimal load and space.

• Smooth Surface & Uniform Aperture: Flat wire weaving creates a smooth, burr-free surface (roughness Ra≤1.0μm) and consistent mesh openings (tolerance ≤±0.1mm), avoiding material adhesion and ensuring precise filtration.

2. Precise Filtration & Breathability

• High Open Area: 40%-70% open area enables efficient air, liquid, or particle flow—critical for filtration, ventilation, and separation applications. Ultra-fine mesh (≤0.1mm aperture) can capture micro-particles (≥5μm) without blocking flow.

• Material Versatility:

◦ Stainless Steel (304/316): Corrosion-resistant, food-grade compliant (FDA, EU 10/2011), ideal for chemical, food, and pharmaceutical filtration.

◦ Low-Carbon Steel: Cost-effective, suitable for light-duty protection and general screening.

◦ Copper/Aluminum: Excellent conductivity and thermal conductivity, used in electronic shielding and heat dissipation.

• Chemical & Temperature Resistance: Withstands -40℃ to 500℃ (stainless steel models) and resists acids, alkalis, and organic solvents—adapting to diverse industrial environments.

3. Easy Processing & Cost-Efficiency

• Cuttable & Customizable: No rigid structure constraints—can be tailored into panels (1×2m, 1.2×2.4m) or rolls (50m/100m) and easily drilled, welded, or bonded to other materials.

• Cost-Effective Production: Simplified weaving process (no pre-crimping or heat setting) reduces manufacturing costs, offering competitive pricing for bulk orders.

• Low Maintenance: Smooth surface is easy to clean with water, steam, or chemical cleaners—reducing downtime for industrial users.

4. Compliance & Eco-Friendliness

• Global Certifications: Meets ASTM A480, ISO 9001, CE, FDA, and REACH standards—test reports for filtration precision, corrosion resistance, and material safety provided for customs clearance.

• 100% Recyclable: Made from recyclable metals, aligning with global green manufacturing trends and appealing to sustainability-focused buyers.

Global Applications (Scene-Specific Solutions)

In North America (USA/Canada), non-crimped woven wire mesh dominates food processing (sugar screening, oil filtration), pharmaceutical manufacturing (powder separation), and electronic shielding (circuit board protection). Stainless steel fine mesh is also used in water treatment plants for micro-particle filtration.

For Europe (EU/UK), food-grade 316 stainless steel mesh is essential for dairy processing (milk clarification) and beverage filtration (wine, beer), complying with strict hygiene regulations. Copper/aluminum mesh is favored for architectural decoration (facade cladding, interior screens) and electromagnetic shielding in telecom facilities.

In Southeast Asia (Indonesia/Vietnam), low-carbon steel woven mesh is widely used in agricultural screening (rice, coffee bean grading), seafood processing (fish sorting), and light-duty construction site fencing. Ultra-fine stainless steel mesh supports electronics manufacturing (semiconductor chip cleaning).

For Africa (Nigeria/South Africa), cost-effective low-carbon steel mesh powers small-scale mining (gemstone sorting), rural water filtration, and market stall partitioning. Its lightweight and easy installation suit remote areas with limited labor resources.

In the Middle East (UAE/Saudi Arabia), 304 stainless steel mesh is critical for air conditioning filtration (desert dust removal) and chemical processing (acid/alkali liquid filtration). Aluminum mesh is used in architectural decoration for its corrosion resistance and heat reflection.

✅ Why Choose Our Non-Crimped Woven Wire Mesh for Global Export?

• Global Compliance & Certification: Meet ASTM A480, ISO 9001, CE, FDA, and SGS standards—full technical reports provided to ensure smooth customs clearance.

• OEM/ODM Expertise: Customize mesh type (plain/twill/Dutch weave), material (stainless steel/steel/copper/aluminum), aperture size (0.05-50mm), wire diameter (0.05-2.0mm), and packaging. Support branded labeling for distributors.

• Flexible MOQ & Competitive Pricing: Accept small trial orders (50 sq.m/10 rolls) for new partners; bulk pricing discounts for orders over 5,000 sq.m to maximize profit margins.

• Comprehensive Global Support: Multilingual technical documents (English, Spanish, Arabic, French) and installation guides; 24/7 after-sales service to resolve issues across time zones.

• Efficient Logistics: Waterproof packaging (plastic wrap + carton) reduces sea freight damage; strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets).

Whether you’re supplying filtration plants, food processors, electronic manufacturers, or architectural firms, our non-crimped woven wire mesh delivers unbeatable flexibility, precision, and value. Join 400+ global partners and leverage the world’s most trusted flexible mesh solution to expand your export business—adaptable, reliable, and built for every light-duty application!