Product Introduction: The Global Backbone of Rigid Mesh Solutions

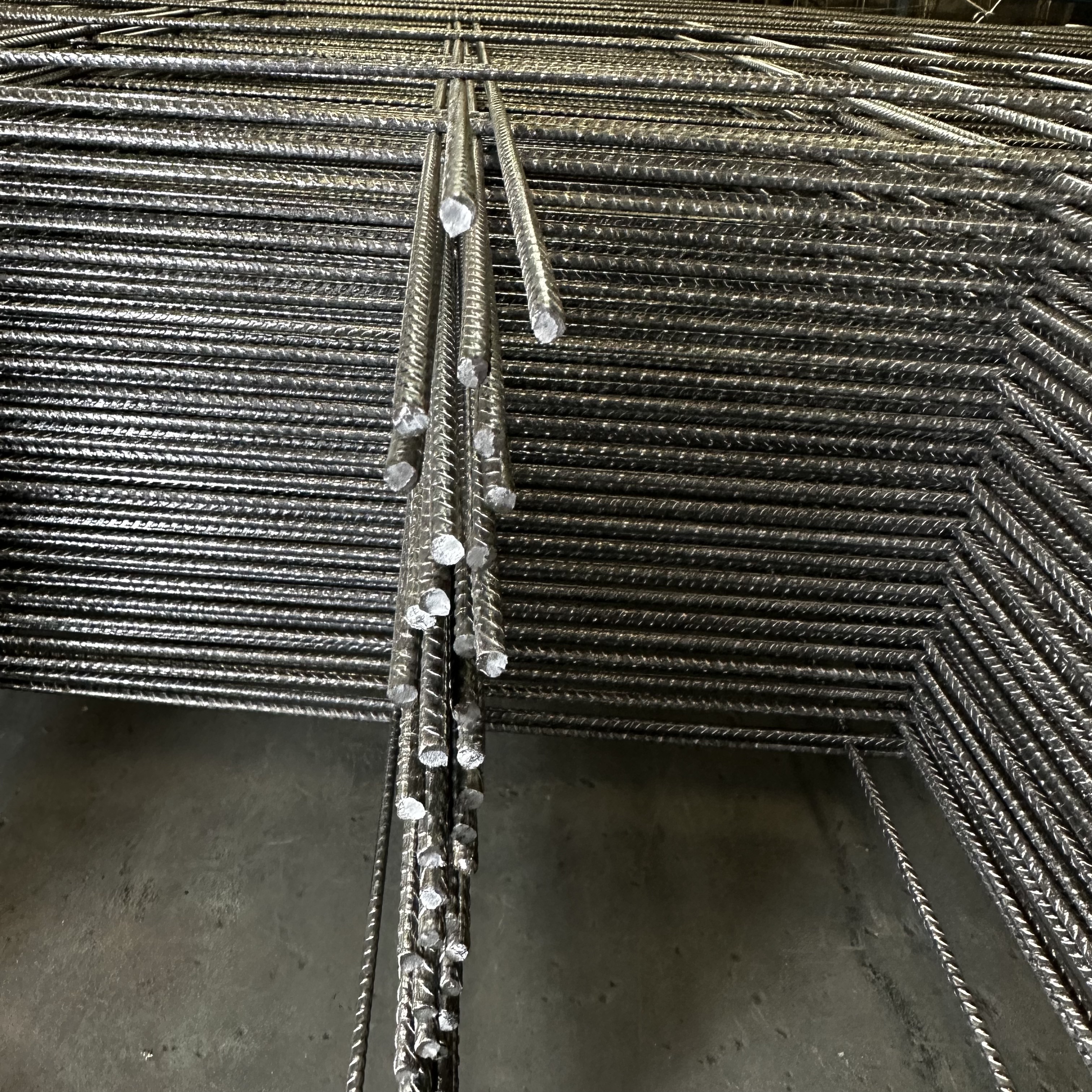

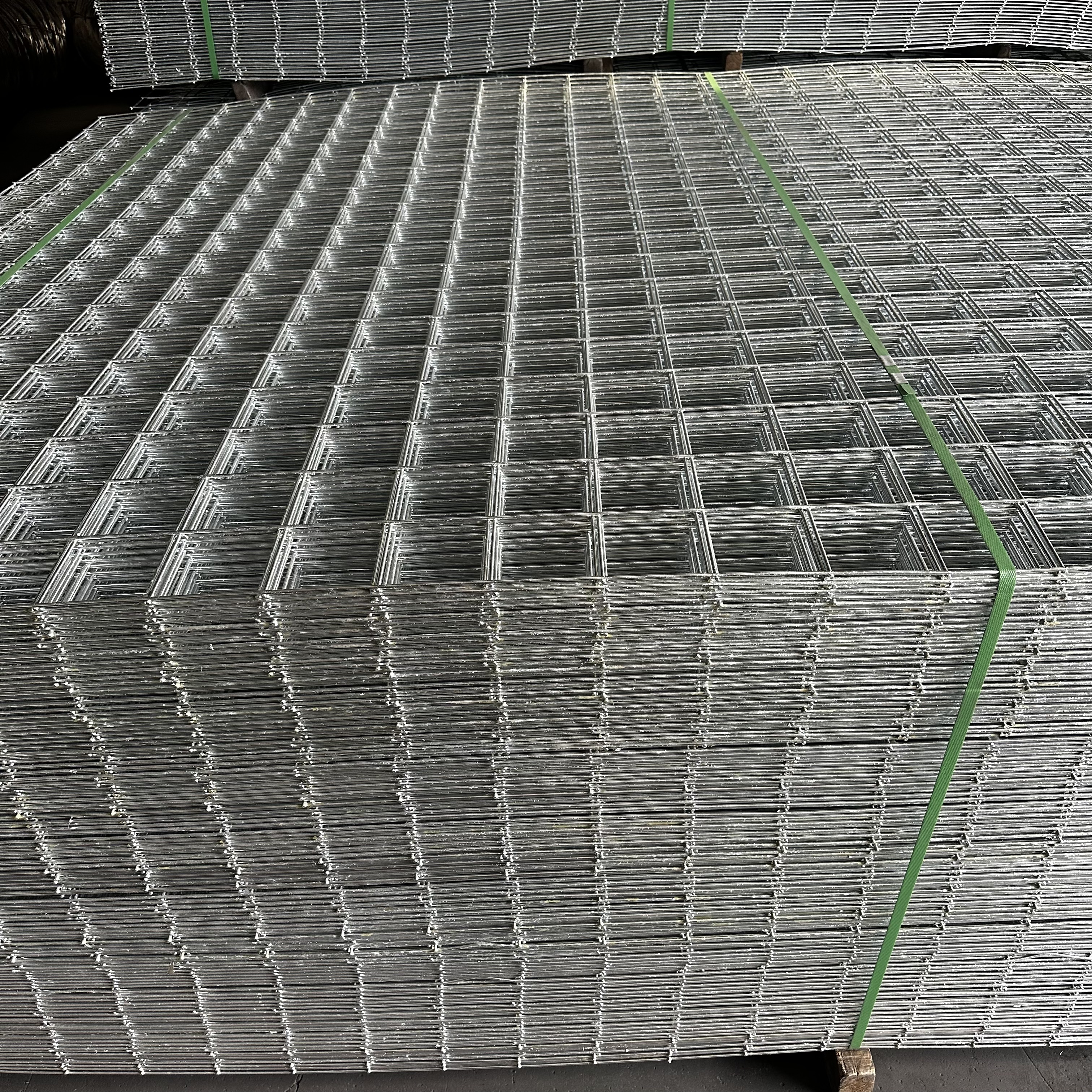

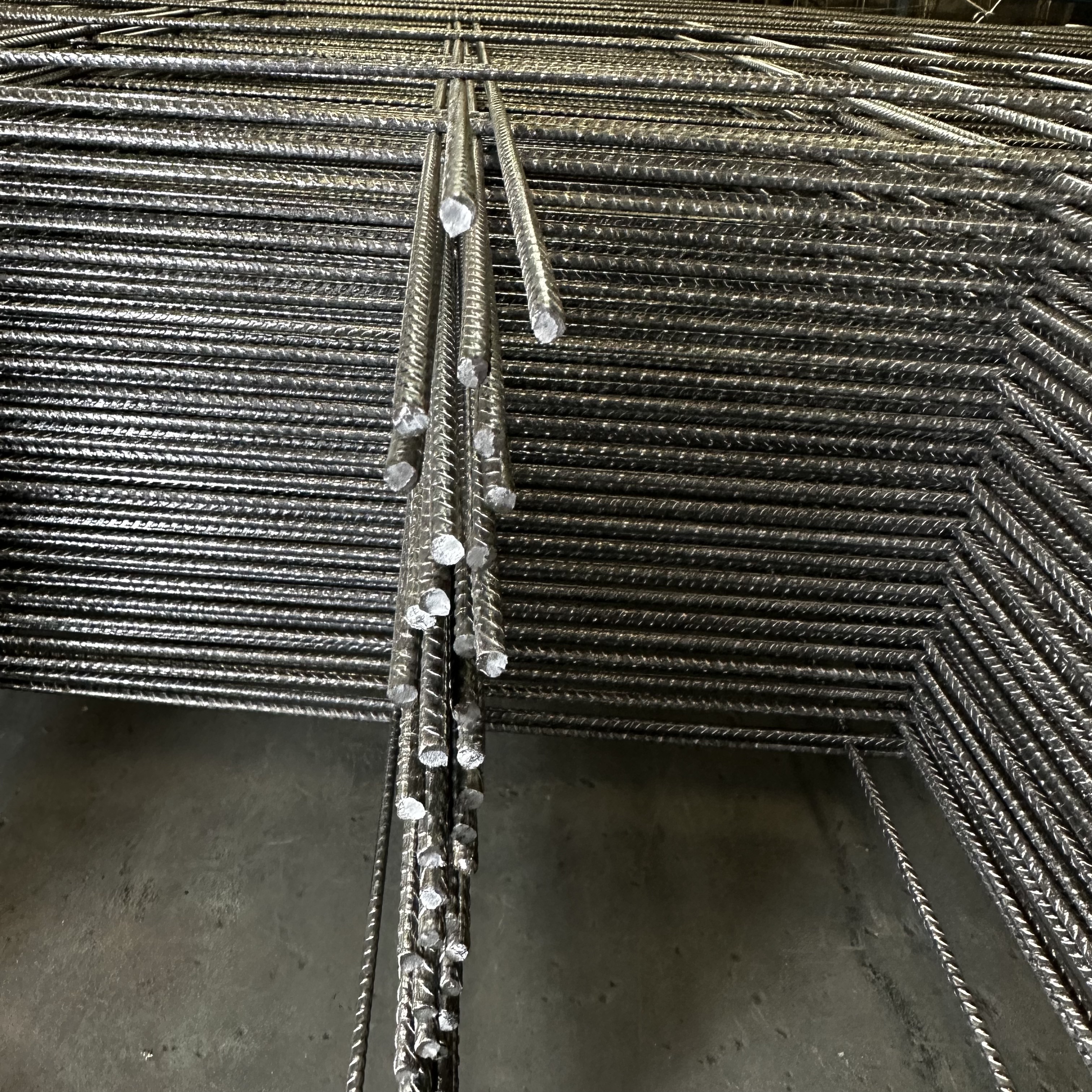

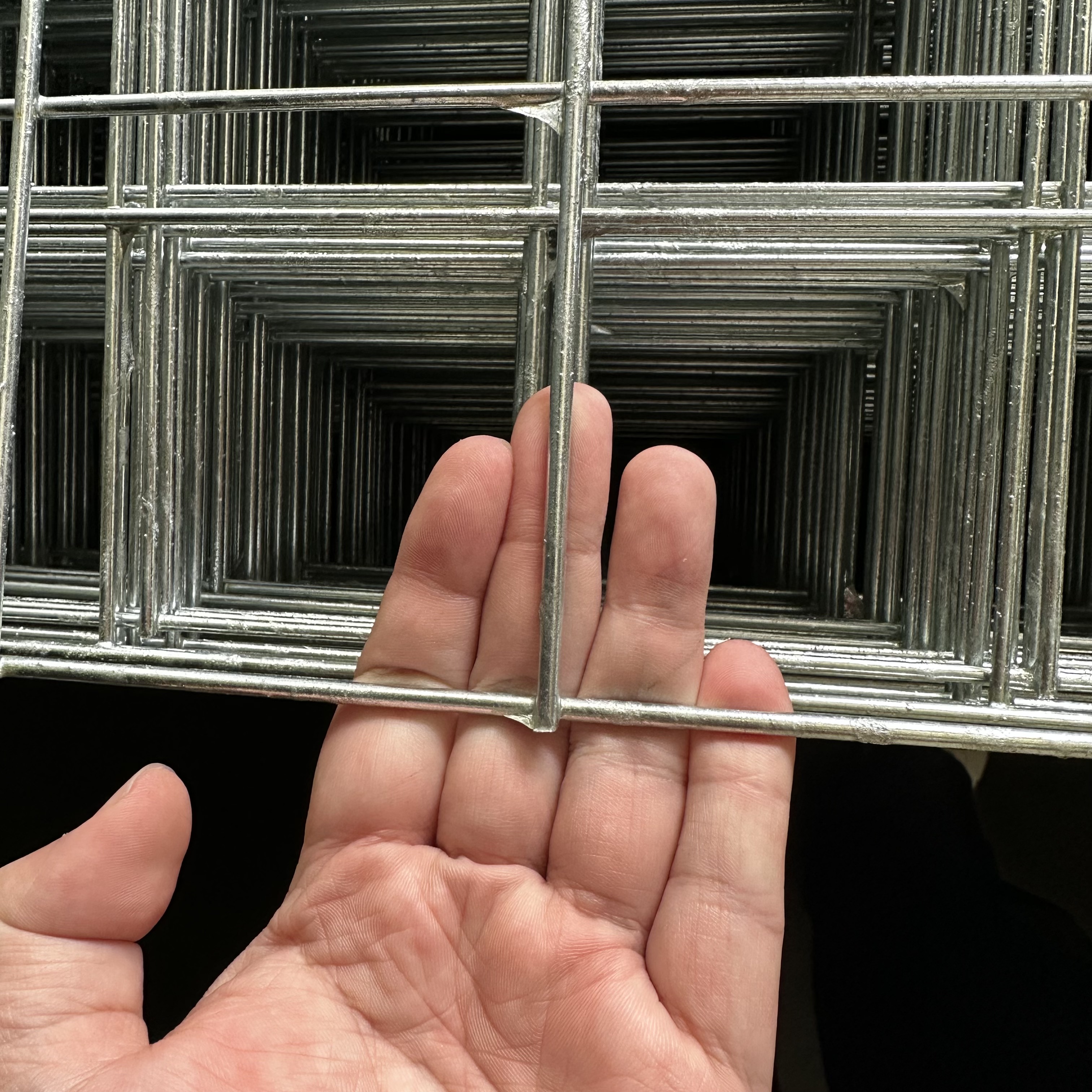

Welded Wire Mesh Panel (also called welded mesh panel or spot-welded wire mesh) is a high-strength, precision-engineered metal product crafted from premium low-carbon steel wire, stainless steel wire, or galvanized steel wire. Defined by its uniform spot-welded structure—where every warp and weft wire intersection is permanently fused—this panel delivers exceptional rigidity, stability, and load-bearing capacity. Compliant with international standards (ASTM A185, ISO 9001, EN 10223-3), it has become an indispensable choice across construction, agriculture, security, and industrial sectors in North America, Europe, Asia-Pacific, Africa, and the Middle East.

Unlike woven mesh, the welded design eliminates wire slippage, ensuring consistent mesh openings and uncompromised performance in harsh environments. With customizable mesh sizes, wire diameters, and surface treatments, it balances durability, functionality, and cost-efficiency—making it the trusted solution for global engineers, contractors, and manufacturers seeking reliability.

��️ Core Features (Global Competitive Advantages)

1. Superior Structural Rigidity & Strength

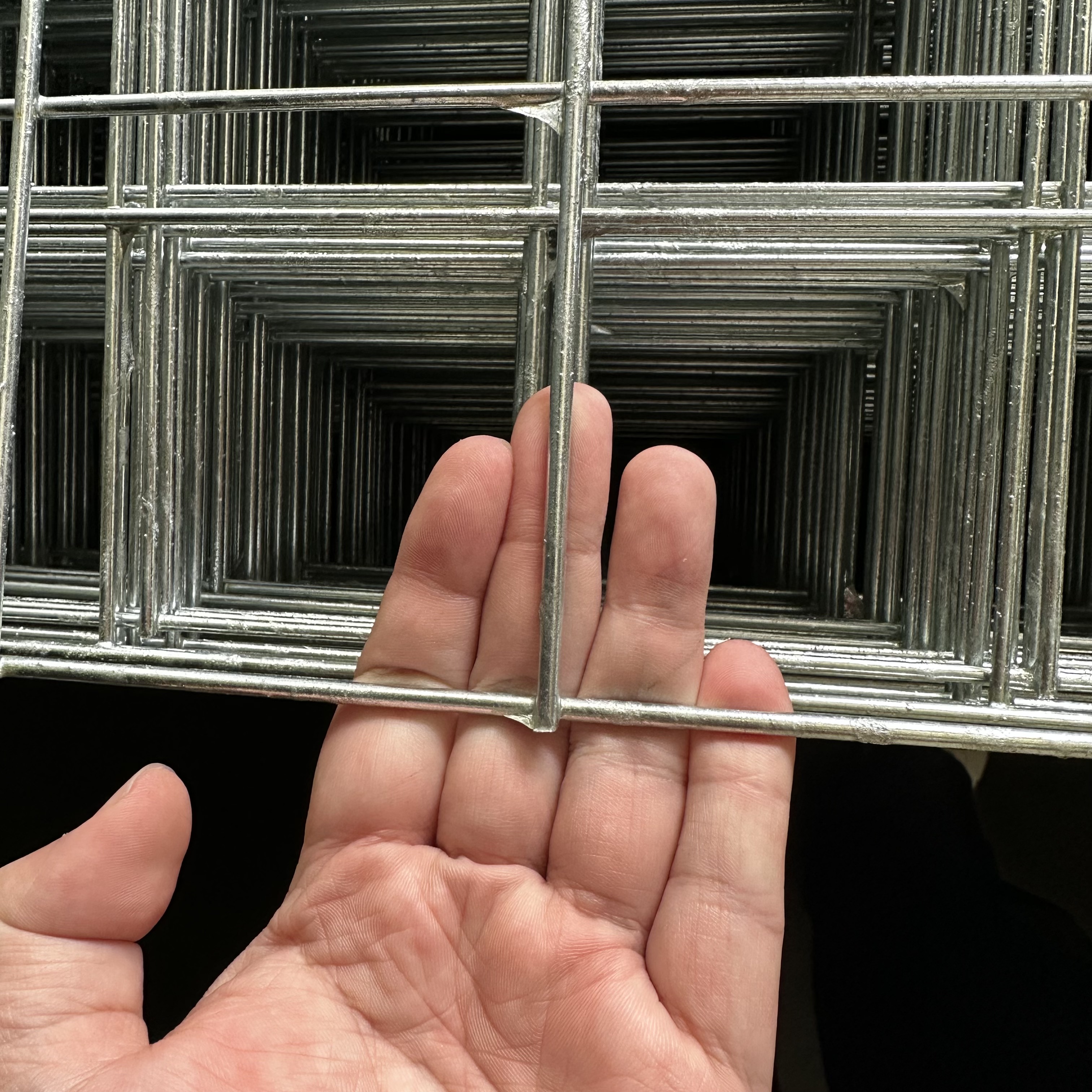

• Precision Spot-Welding Technology: Every wire intersection is fused via high-frequency resistance welding, with weld shear strength ≥2500N—no loose joints or deformation under heavy loads (up to 300kg/㎡). The rigid structure maintains flatness (error ≤1mm/m) even for large panels (up to 3×6m).

• High-Tensile Wire Construction: Wire diameters range from 1.0mm to 6.0mm, with tensile strength ≥500MPa for low-carbon steel and ≥600MPa for stainless steel variants. Reinforced edges (optional) enhance perimeter strength, preventing damage during installation.

• Uniform Mesh Openings: Mesh sizes from 5×5mm to 100×100mm (tolerance ≤±0.2mm) ensure consistent performance for screening, reinforcement, or containment—critical for construction and industrial applications.

2. All-Climate Corrosion Resistance & Durability

• Tailored Surface Treatments for Global Climates:

◦ Hot-dip galvanizing (≥120g/㎡ zinc layer): Salt spray resistance ≥800 hours; perfect for humid Southeast Asia, coastal North America, and tropical Africa—protects against rain, salt mist, and humidity.

◦ Electro-galvanizing (≥30g/㎡ zinc layer): Cost-effective corrosion protection; ideal for dry inland areas (Africa, Middle East) and indoor applications.

◦ 304/316 Stainless Steel: Ultimate corrosion resistance; immune to saltwater and chemical erosion—essential for marine engineering and coastal construction in the Mediterranean and Caribbean.

◦ Polyester Powder Coating: RAL color options (black, gray, green) with UV resistance ≥5000 hours; no fading or peeling—suited for residential landscaping and commercial security barriers in Europe and North America.

• Extreme Temperature Adaptability: Operates stably from -40℃ to 80℃; resists frost cracking in Northern Europe and heat deformation in Middle Eastern deserts. Service life ranges from 8 to 25 years depending on surface treatment.

3. Versatility & Customization

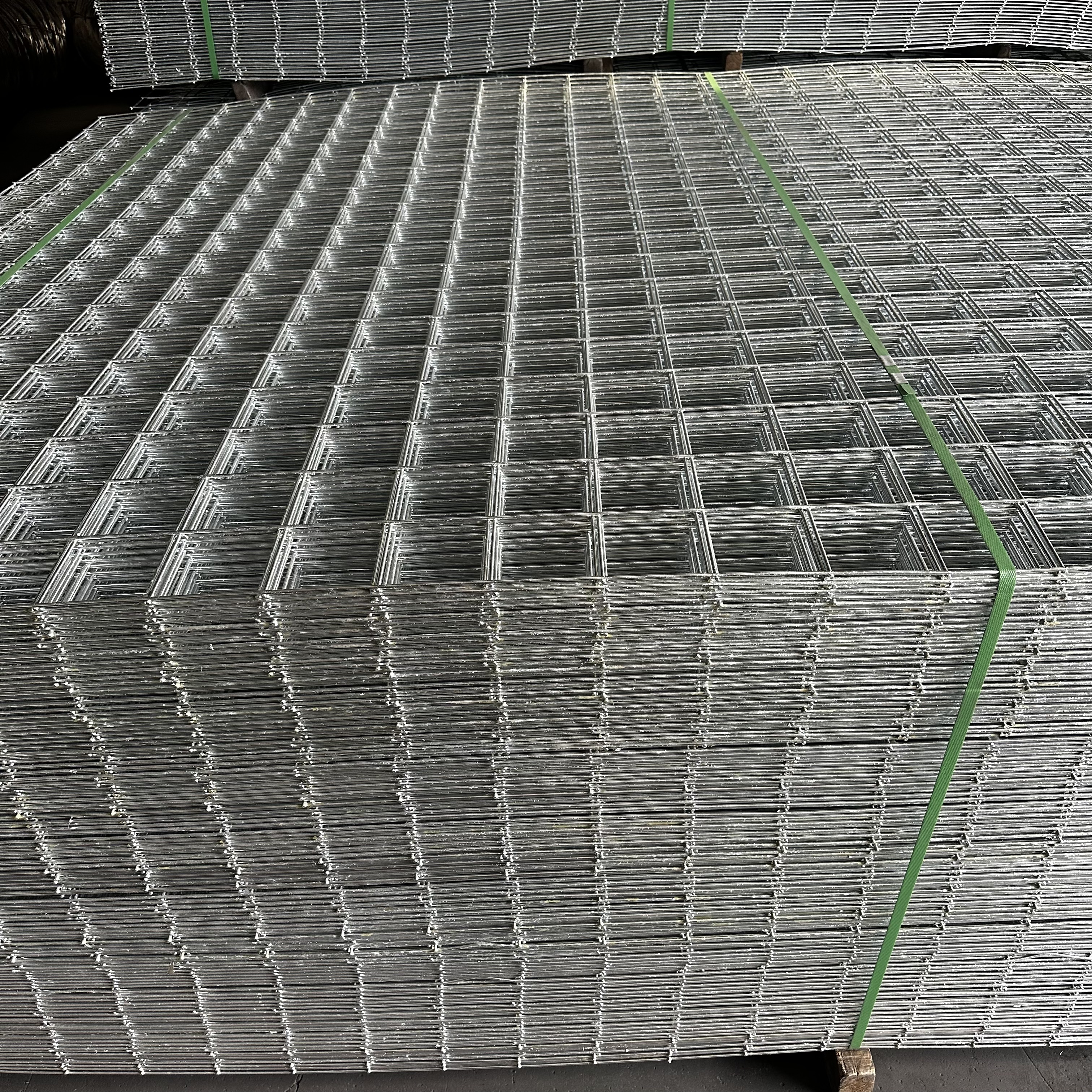

• Full-Spec Customization: Mesh sizes (5×5mm-100×100mm), panel dimensions (1×2m to 3×6m), wire diameters (1.0-6.0mm), and surface treatments can be tailored to regional needs. Supports custom edge treatments (flanging, bending) for seamless installation.

• Multi-Application Adaptability: Suitable for concrete reinforcement, livestock fencing, security barriers, industrial screening, and residential landscaping—one product fits diverse industry needs, reducing inventory costs for distributors.

• Cost-Efficient Options: Budget-friendly electro-galvanized panels for Africa’s infrastructure projects; premium stainless steel panels for Europe’s precision manufacturing—grades to fit every market segment.

4. Eco-Friendly & Compliance-Certified

• 100% Recyclable Material: Made from recyclable steel, aligning with EU REACH, RoHS, and North American LEED green building standards—appealing to sustainability-focused buyers.

• Global Quality Assurance: Full test reports for weld strength, corrosion resistance, and mesh uniformity provided with every order—ensuring smooth customs clearance worldwide.

�� Global Applications (Scene-Specific Solutions)

In North America (USA/Canada), welded wire mesh panels are a staple in construction—used for concrete slab reinforcement, highway bridge decking, and basement wall strengthening. Hot-dip galvanized panels secure agricultural livestock enclosures (cattle, horses) and residential security fencing, while stainless steel panels are favored for food processing (screening) and marine dock reinforcement.

For Europe (EU/UK), powder-coated welded mesh panels are popular for residential garden fencing and public park security barriers, blending aesthetics with durability. Stainless steel 316 panels are critical for coastal construction (sea walls, promenades) in the Mediterranean, resisting saltwater corrosion. Small-mesh panels are also used in industrial filtration and pharmaceutical manufacturing.

In Southeast Asia (Indonesia/Vietnam), hot-dip galvanized welded mesh panels protect palm oil plantations and fish ponds from tropical storms and animal intrusion. They’re widely used for low-cost housing reinforcement, supporting the region’s booming infrastructure development. Large-mesh panels are used for construction site safety barriers.

For Africa (Nigeria/South Africa), electro-galvanized welded mesh panels are a cost-effective solution for mining site safety fencing, rural water well filtration, and open-air market stall construction. Lightweight panels are preferred for easy transportation across remote areas, while heavy-duty panels secure livestock corrals and grain storage silos.

In the Middle East (UAE/Saudi Arabia), zinc-aluminum coated and 304 stainless steel panels are critical for desert construction—used in high-rise building facades, oil refinery security perimeters, and desert farm irrigation systems. The rigid structure withstands sandstorms and extreme heat, while corrosion-resistant treatments prevent rust from desert humidity.

✅ Why Choose Our Welded Wire Mesh Panel for Global Export?

• Global Compliance & Certification: Meet ASTM A185, ISO 9001, CE, and SGS standards—test reports available for every order to eliminate customs clearance delays.

• OEM/ODM Expertise: Customize mesh size, wire diameter, panel dimensions, surface treatment, and packaging; support branded labeling for distributors to build local market recognition.

• Flexible MOQ & Competitive Pricing: Accept small trial orders (100 panels) for new partners; bulk pricing discounts for orders over 10,000 units to maximize your profit margin.

• Comprehensive Global Support: Multilingual technical documents (English, Spanish, Arabic, French) and installation guides; 24/7 after-sales service to resolve customer issues across time zones.

• Efficient Logistics: Waterproof packaging with steel pallets reduces sea freight damage; strategic warehouses in China, Europe, and the USA enable fast delivery to global destinations—cutting lead times by 30% for key markets.

Whether you’re supplying construction contractors, agricultural enterprises, security firms, or industrial manufacturers, our welded wire mesh panel delivers unbeatable rigidity, durability, and versatility. Join 500+ global partners and leverage the world’s most trusted welded mesh solution to expand your export business—reliable, adaptable, and built for every industry!