Premium Safety Protection Net: Global Solution for Hazard Prevention & Site Security

Falls, falling objects, debris intrusion, and animal damage pose severe threats to global construction sites, industrial workshops, agricultural plantations, and public areas—leading to safety accidents, property losses, and operational disruptions. Our premium safety protection net, engineered with global safety standards and diverse environmental adaptability in mind, delivers reliable protection, durable performance, and multi-scenario versatility. Trusted by contractors, industrial enterprises, and distributors in 120+ countries across North America, Europe, Africa, Asia-Pacific, and South America, it’s the ultimate safety barrier for securing lives, assets, and operations worldwide.

🌍 What Makes Our Safety Protection Net Globally Trusted?

We don’t just manufacture safety nets—we tailor them to the unique safety regulations, environmental conditions, and application needs of different regions. Every feature is designed to eliminate potential hazards and meet international safety standards, ensuring peace of mind wherever you are:

✅ High-Strength Materials & Reliable Protection

- Premium Raw Material Selection: Mainly adopts 100% virgin HDPE, PP, and high-tenacity nylon (polyamide) resins, with optional fiberglass-reinforced (FRP) materials for high-temperature and corrosion-prone scenarios. HDPE/PP nets balance cost-effectiveness and impact resistance, ideal for general construction and agricultural use; nylon nets boast ultra-high tensile strength (≥35MPa) and elongation at break (≥25%), suitable for high-risk fall protection in construction sites; FRP nets resist high temperatures (up to 150℃) and chemical corrosion, perfect for European chemical plants and Asian industrial workshops. All materials are non-toxic, odorless, and comply with EU EN 1263-1, US OSHA 1926.502, and ISO 14688 standards, ensuring compliance with global safety regulations 13.

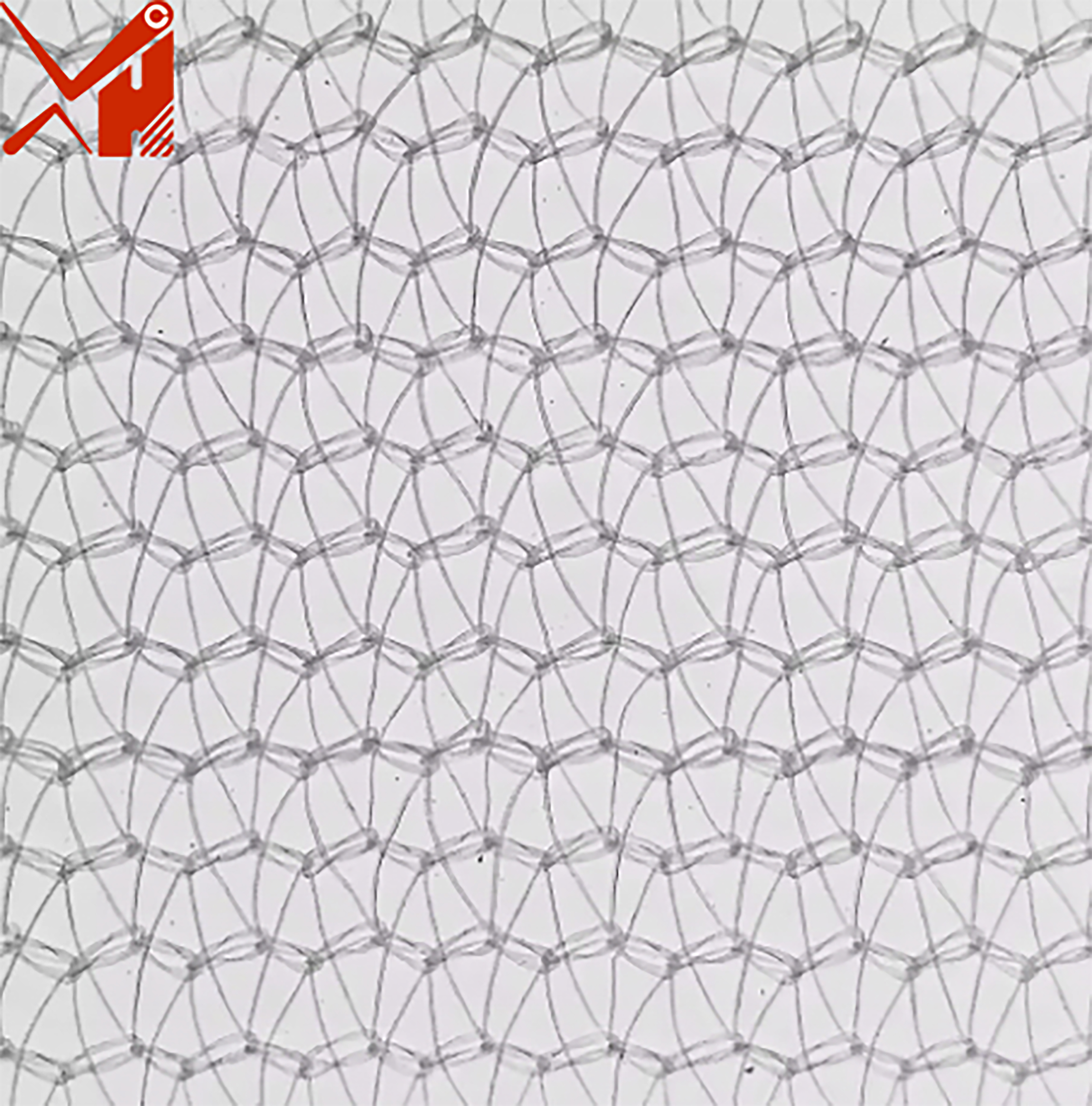

- Reinforced Structure & Impact Resistance: Adopts a double-weave or knotted weave structure, enhancing mesh stability and load-bearing capacity. The net can withstand an impact force of 100-500J (adjustable according to specifications), effectively blocking falling objects (such as construction debris, agricultural hail, and industrial parts) and preventing falls. For high-risk scenarios (e.g., high-rise construction in North America), we add reinforced edges and load-bearing ropes, ensuring the net does not break or deform under extreme loads 46.

- All-Weather Durability: Infused with 3-5% UV stabilizers and anti-aging agents during production, the net can withstand 6000+ hours of strong sunlight exposure, suitable for outdoor use in high-UV regions like Africa and the Middle East. It resists extreme temperatures (-40℃ to 90℃), heavy rain, snow, salt spray corrosion, and mold, with a service life of 3-8 years (depending on material) — far exceeding ordinary safety nets 24.

✅ Customizable Specifications for Global Needs

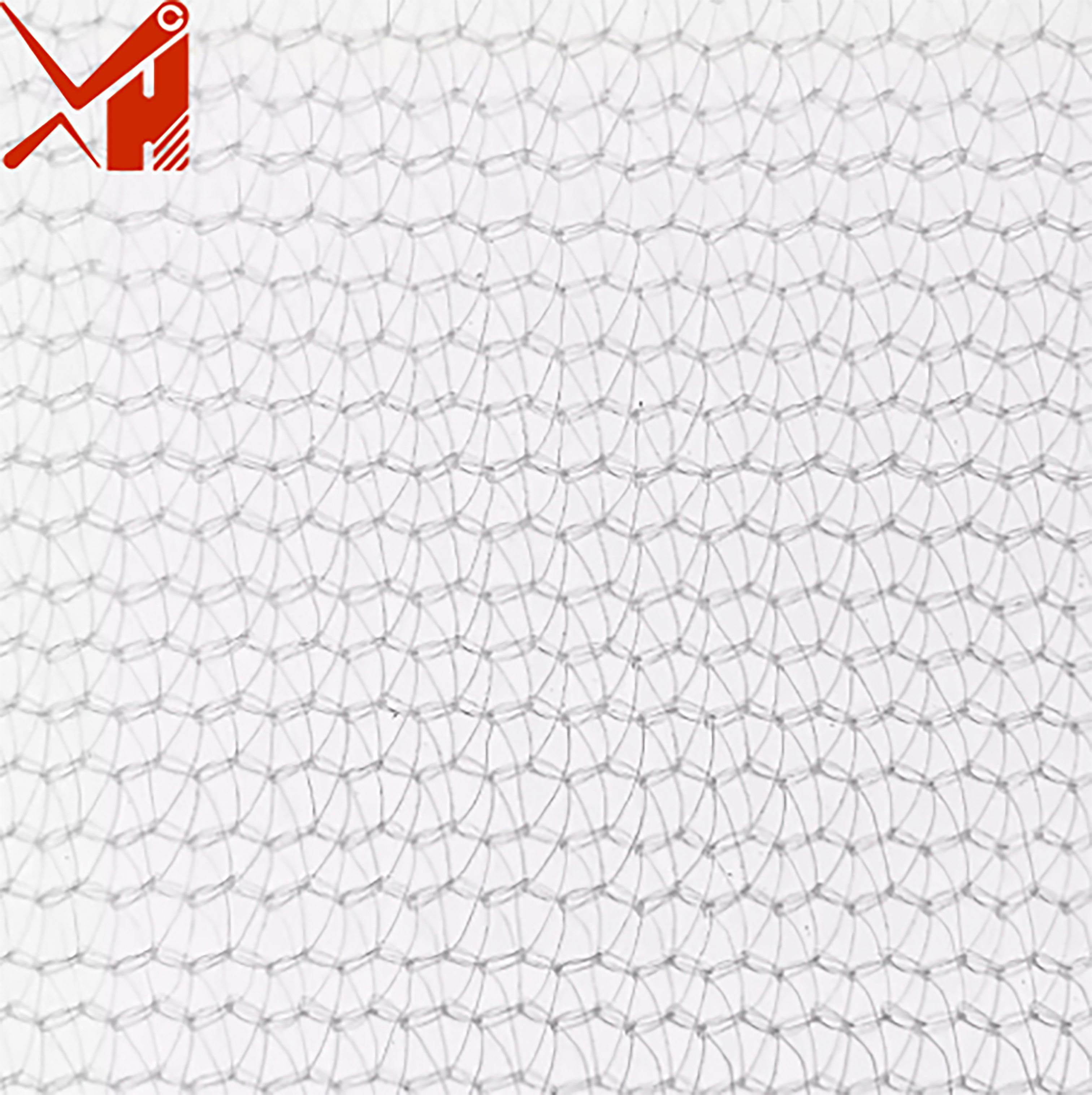

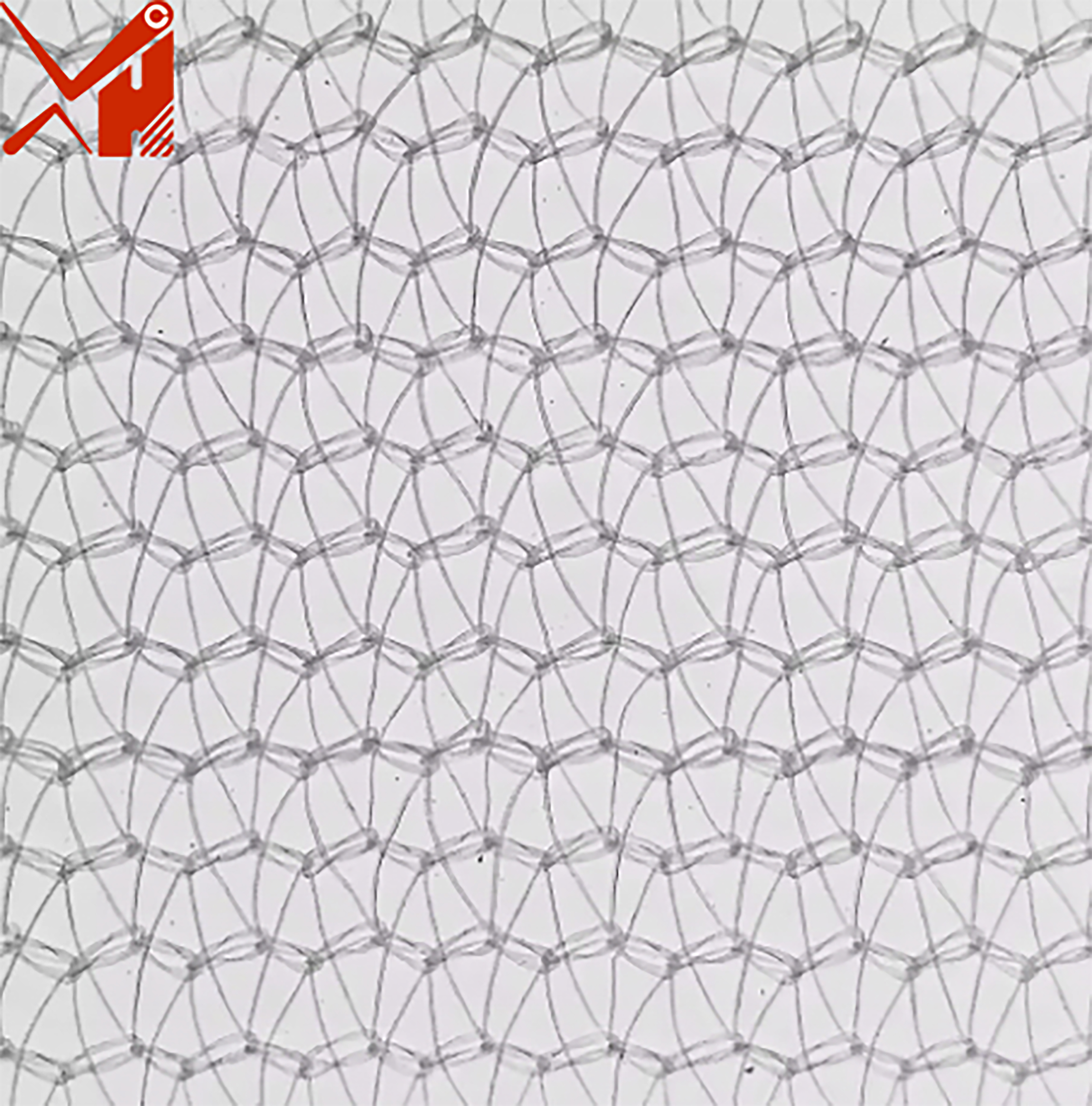

- Precision Mesh Size & Density: Support full customization of mesh size (0.5×0.5cm to 20×20cm) and mesh density to match regional application needs: ① Fine mesh (0.5×0.5-1×1cm) nylon/HDPE nets for European industrial workshops (blocking small debris) and Asian electronic factories (anti-static and dust-proof); ② Medium mesh (2×2-5×5cm) HDPE/PP nets for North American construction safety nets and African agricultural anti-hail nets; ③ Large mesh (10×10-20×20cm) PP nets for South American livestock fencing and Asian construction site perimeter protection 15.

- Flexible Sizes & Color Options: Width ranges from 1m to 15m, length from 5m to 100m (custom sizes available for large-scale projects like stadiums and high-speed rail construction). Color options are optimized for safety and regional preferences: ① High-visibility colors (orange, yellow) for construction sites worldwide (enhancing warning effect); ② Green for European agricultural plantations (blending with crops); ③ Black for North American industrial workshops (dust-proof and aesthetic) 46.

- Easy Installation & Maintenance: Equipped with reinforced eyelets (every 50-100cm) and load-bearing ropes for quick and secure installation—no professional equipment required. The smooth surface is easy to clean with water or detergent, and no regular maintenance (such as painting or anti-rust treatment) is needed. Lightweight design (80-400g/m²) reduces transportation and installation costs by 30% compared to metal protective barriers 67.

✅ Multi-Functional Advantages Beyond Protection

- Safety Warning & Perimeter Control: High-visibility colors and clear mesh structure serve as effective warning signs, preventing unauthorized entry into hazardous areas (e.g., construction sites, industrial zones). It can also be used as a perimeter fence for public areas (parks, stadiums) and private properties, enhancing security 27.

- Ventilation & Light Transmission: Open mesh structure ensures 60-80% air circulation and light transmission, avoiding air stagnation and dark environments in enclosed areas (e.g., construction scaffolding, greenhouse protection). In agricultural scenarios, it does not affect crop photosynthesis 15.

- Eco-Friendly & Cost-Effective: Recyclable materials align with global sustainability trends, helping customers meet EU EPD (Environmental Product Declaration) requirements. Compared to metal protective equipment, it has lower production and maintenance costs, and can be reused multiple times, reducing long-term operational expenses 39.

🏭 Advanced Manufacturing Process & Professional Surface Treatment

The reliable performance and global adaptability of our safety protection net originate from mature manufacturing processes and targeted surface treatment technologies, ensuring consistent quality and compliance with international safety standards:

1. Core Manufacturing Processes

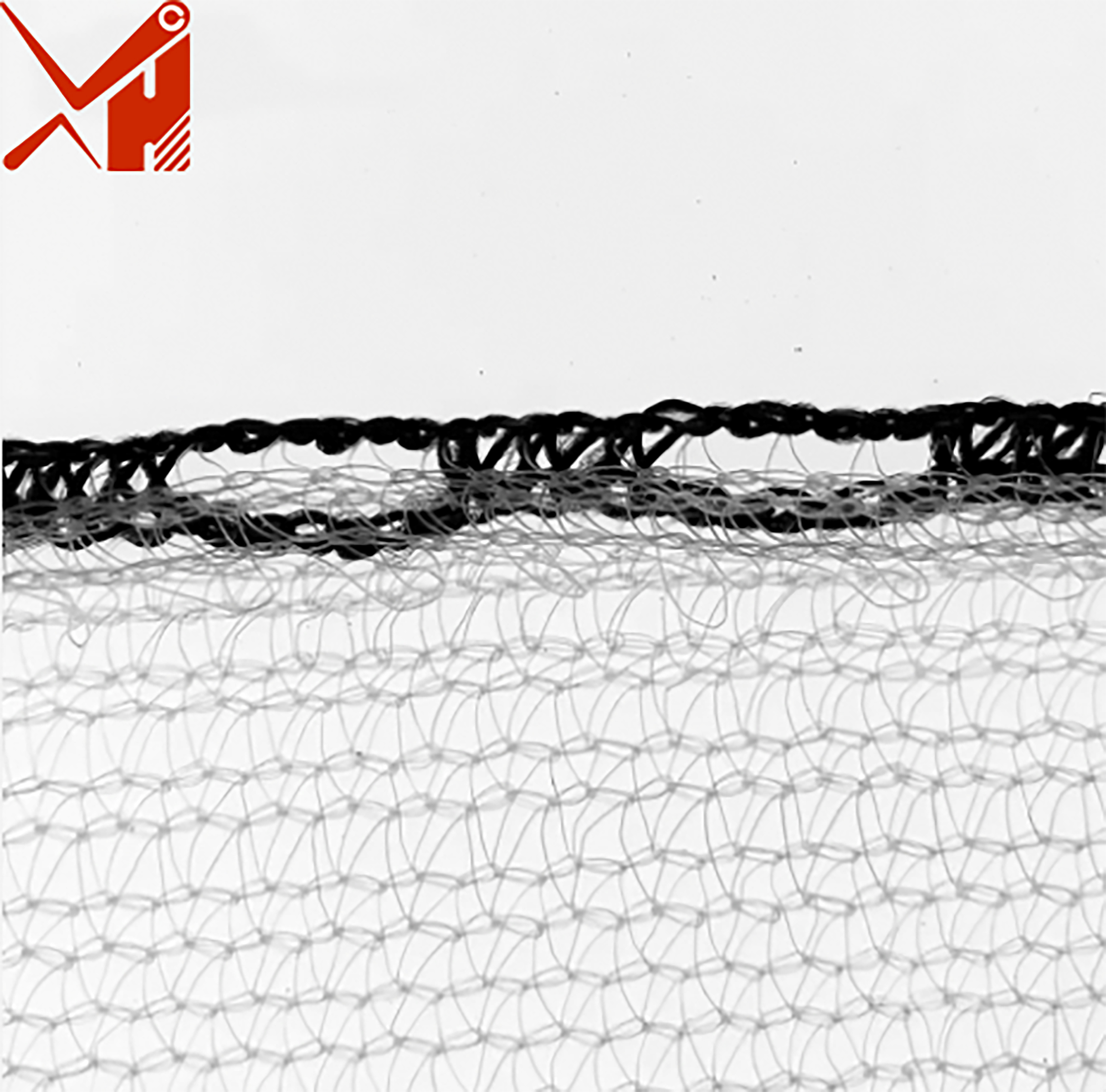

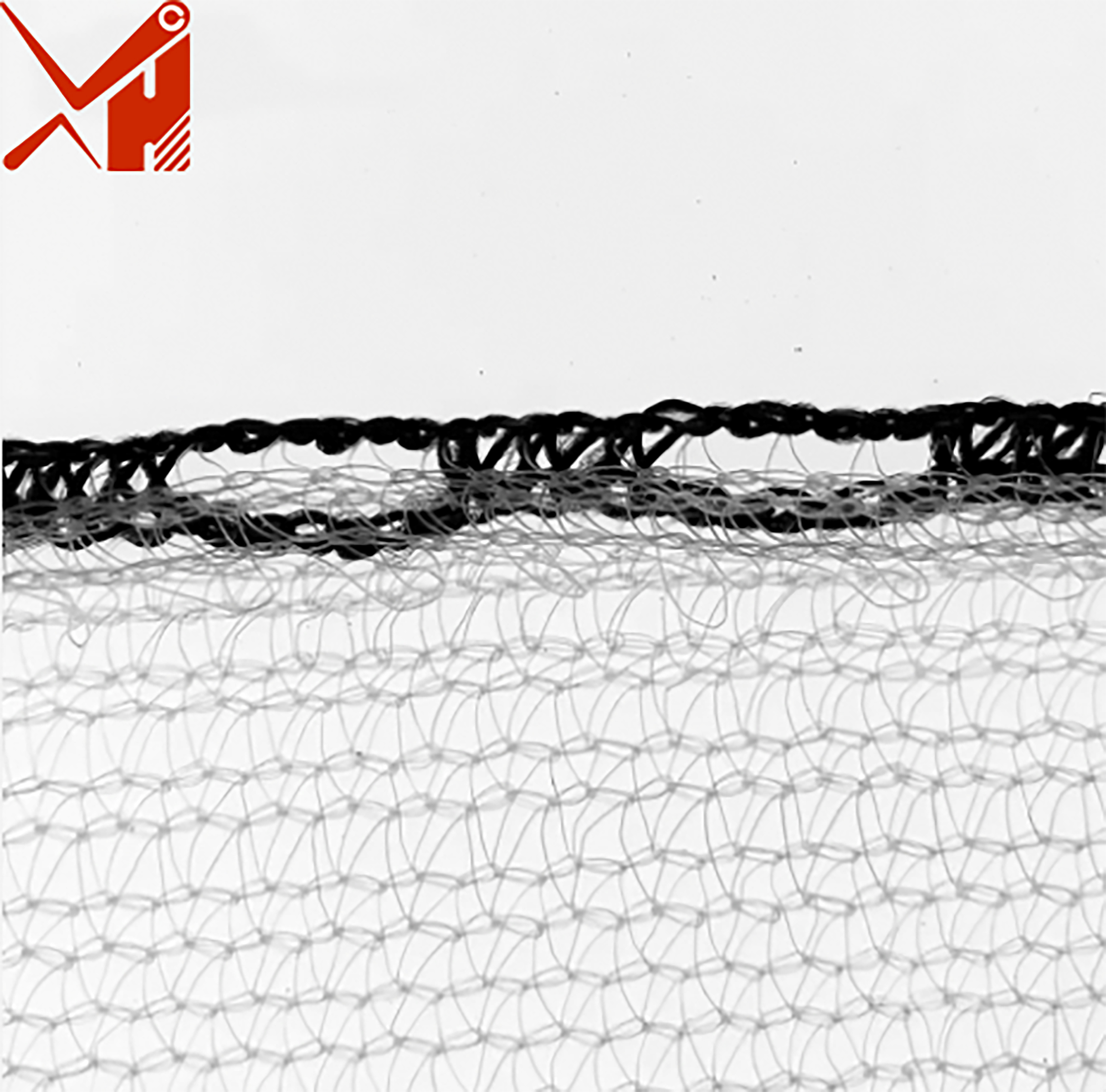

- High-Speed Precision Weaving: Using German-imported intelligent weaving machines (120-180 picks/min) with automatic tension control and yarn breakage detection systems, we achieve uniform mesh size (error ≤±0.1mm) and tight weaving. This process is suitable for mass production of HDPE/PP/nylon safety nets, with an output of 300-500kg/h and a defective rate ≤0.5%. For high-tenacity nylon nets, we adopt a knotted weave process to enhance mesh stability and load-bearing capacity 4.

- Ultrasonic Edge Sealing & Reinforcement: A critical post-processing step to ensure safety performance. We use ultrasonic edge sealing technology (sealing width 10-15mm) to fuse the net edges, preventing fraying and yarn shedding. For high-load scenarios, we add polyester load-bearing ropes (tensile strength ≥5kN) along the edges, further enhancing the net's overall load-bearing capacity. Automatic precision cutting machines ensure size consistency (error ≤±5mm) 6.

- Molding & Processing for Special Materials: For FRP safety nets, we adopt compression molding technology (120-150℃, 15-25MPa) to mix resin and fiber materials, ensuring uniform material distribution and high-temperature resistance. For anti-static nets, we add conductive fibers during the weaving process, achieving stable anti-static performance (surface resistance 10⁶-10⁹Ω) 7.

2. Targeted Surface Treatment Technologies

- UV-Resistant Coating: Core treatment for outdoor use in high-UV regions. After plasma cleaning, we spray acrylic UV-resistant coating (containing 3-5% UV absorber) to form a dense protective layer (5-8μm thickness). This enhances UV resistance by 50%, extending the net's service life to 8-10 years. The coating complies with EU REACH standards 2.

- Corrosion-Resistant Treatment: For coastal areas (Southeast Asia, South America) and chemical industries, we add anti-corrosion additives during raw material mixing and apply a fluorocarbon coating. The treated net can withstand 2000+ hours of salt spray corrosion (ASTM B117 standard) and resist most chemical solvents4.

- Anti-Static Treatment: Optional for Asian and European industrial scenarios. We apply a conductive anti-static coating on the net surface, ensuring long-term anti-static performance without affecting air permeability. It meets the anti-static requirements of industrial clean rooms 7.

- High-Visibility Coating: For construction safety nets, we use high-reflective, weather-resistant coatings (color fastness ≥4 grade) to enhance visibility in low-light conditions (e.g., dawn, dusk, and rainy days), further improving safety warning effects 6.

🌍 Global Application Scenarios: Securing Every Industry

Our safety protection net is widely used in various industries worldwide, providing targeted safety solutions for different regional needs:

🏗️ Construction & Infrastructure

- Construction Safety Nets: High-tenacity nylon/HDPE nets for North American high-rise construction, European bridge construction, and Asian subway projects—preventing falls and blocking falling objects. High-visibility colors enhance on-site safety warning 46.

- Scaffolding & Perimeter Protection: Medium mesh PP/HDPE nets for construction site scaffolding and perimeter fencing in Africa and South America—preventing debris intrusion and unauthorized entry. Lightweight design facilitates quick installation 7.

- Road & Railway Construction: Anti-corrosion HDPE nets for Southeast Asian coastal road construction and European high-speed rail projects—protecting construction personnel and passing vehicles from hazards4.

🏭 Industry & Manufacturing

- Workshop Safety & Dust-Proof: Fine mesh anti-static nets for Asian electronic factories and European chemical plants—blocking small debris and preventing static electricity. High-temperature resistant FRP nets for industrial furnaces and smelting workshops 79.

- Material Storage & Handling: Heavy-duty HDPE nets for North American warehouse storage areas and African open-air material yards—preventing material falling and dust pollution. It can also be used as a lifting net for light materials 6.

🍎 Agriculture & Horticulture

- Anti-Hail & Bird Protection Nets: Medium mesh HDPE nets for European fruit orchards, North American vineyards, and Asian vegetable plantations—protecting crops from hail, bird damage, and wind erosion. Green color blends with crops, avoiding light遮挡 15.

- Livestock Fencing: Large mesh PP nets for African cattle farms, South American poultry coops, and Asian pig farms—securing livestock and preventing escape. Corrosion-resistant treatment adapts to animal waste environments 46.

🏛️ Public Areas & Daily Life

- Public Area Security: High-visibility safety nets for European stadiums, North American parks, and Asian commercial plazas—preventing falls from heights and securing public safety. Customizable sizes fit various architectural structures 7.

- Residential Safety: Fine mesh HDPE nets for balcony railings and windows in Asian high-rise residential buildings—protecting children and pets from falling. Aesthetic design matches home decoration 6.

- Transportation Security: Safety nets for Middle Eastern highway guardrails and African railway platforms—preventing debris from entering the road/railway and ensuring traffic safety 4.

🌍 Your Trusted Global Safety Protection Net Partner

We understand the complexities of global trade and the importance of safety compliance. We provide comprehensive support to ensure smooth cooperation:

- Global Safety Standard Compliance: Passes ISO 9001 quality certification, EU EN 1263-1, US OSHA 1926.502, and ASTM standards. Provides complete SGS/Intertek test reports (tensile strength, impact resistance, UV resistance, corrosion resistance) for hassle-free customs clearance in 120+ countries 39.

- Full Customization Service: Tailor material, mesh size, size, color, and packaging to regional safety regulations and application needs. Support OEM/ODM with branded packaging (logo printing, multilingual safety instructions) to help you build local brand influence.

- Flexible Cooperation Terms: Accept small trial orders (10 rolls/pieces) for new partners; bulk orders enjoy tiered pricing discounts. Short production lead time: 7-15 days for standard orders, 15-25 days for custom orders.

- Efficient Logistics & Multilingual Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide technical documents and safety manuals in 5+ languages (English, Spanish, Portuguese, Arabic, French) and 24/7 after-sales service to solve your problems anytime.

📞 Secure Your Business with Custom Safety Solutions

Whether you’re a construction material distributor in North America, an industrial safety supplier in Europe, an agricultural supplies dealer in Africa, or a property manager in Asia-Pacific, we have the perfect safety protection net to meet your local safety needs. Send your inquiry now to get free samples, a customized quote, and detailed product specifications. Let’s work together to build a safer world!