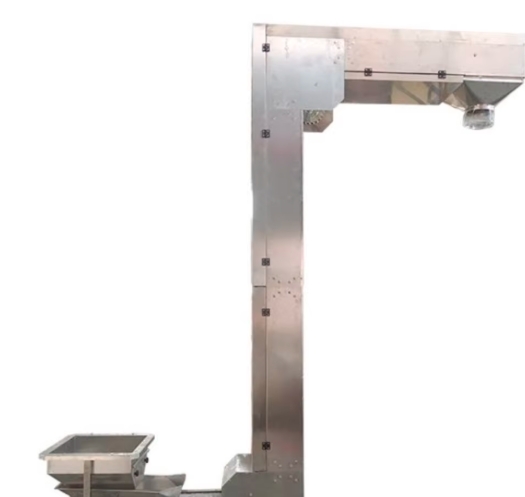

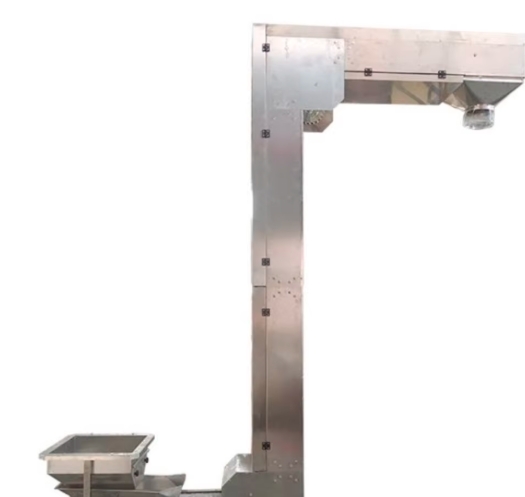

Z-Type Bucket Stainless Steel Vertical Conveyor: Efficient, Corrosion-Resistant for Global Material Lifting Needs

When global industries require efficient, stable vertical lifting and horizontal conveying of bulk, granular, or powdery materials—while overcoming space constraints and harsh environmental challenges—our Z-Type Bucket Stainless Steel Vertical Conveyor emerges as the optimal solution. Integrating the superior corrosion resistance of premium stainless steel with the innovative Z-type dual vertical-horizontal conveying structure, this conveyor redefines the efficiency of material lifting and transferring. Unlike traditional vertical conveyors that suffer from material leakage, uneven feeding, and poor adaptability to corrosive/high-temperature environments, our product is tailor-made to meet the diverse needs of 120+ countries across North America, Europe, Asia-Pacific, Africa, and South America. Trusted by food processing, pharmaceutical, chemical, mining, and grain storage industries worldwide, it’s not just a conveying device; it’s a space-saving, cost-effective investment in optimizing your production workflow.

🌟 Core Features: Why It’s Globally Preferred for Material Lifting

Every detail of our Z-type bucket stainless steel vertical conveyor is engineered to solve the critical pain points of global industrial material lifting—from space utilization and material integrity to environmental adaptability. It delivers consistent, reliable performance in the most demanding scenarios:

✅ Premium Stainless Steel & Global Standard Compliance

- Grade-Specific Material Selection: We offer 304/316L/310S stainless steel to match diverse global working environments. 304 stainless steel balances cost-effectiveness and corrosion resistance, ideal for European and Asia-Pacific grain storage, food processing, and light chemical industries; 316L boasts enhanced resistance to acids, alkalis, salt spray, and chloride corrosion, perfect for North American and Southeast Asian pharmaceutical, marine, and chemical processing (complying with EU FDA & US NSF standards); 310S withstands high temperatures up to 1100℃, suitable for Middle Eastern and African high-temperature material lifting (e.g., metallurgical powder, cement clinker) 13.

- Comprehensive Global Certifications: All conveyors pass strict quality inspections to meet EU CE, US UL, ISO 9001, EU EN 10088, and US ASTM A240 standards. Food-grade models fully comply with FDA 21 CFR Part 177 and GMP Class 100,000 standards, while chemical-resistant models meet ASTM G48 corrosion resistance requirements. These certifications ensure hassle-free customs clearance and market access worldwide 25.

- Hygienic & Green Design: Non-toxic, heavy-metal-free stainless steel ensures no material contamination—critical for food, pharmaceutical, and cosmetic industries. The enclosed structure prevents dust leakage and material pollution, complying with EU RoHS and environmental protection standards. All materials are 100% recyclable, aligning with global green production trends 46.

✅ Innovative Z-Type Structure & Superior Conveying Performance

- Space-Saving Z-Type Design: The unique Z-type structure integrates two vertical lifting sections and one horizontal conveying section, enabling material to be lifted from the lower level, transferred horizontally, and then lifted to the target height—all in one continuous process. This design reduces the need for multiple conveying devices, saving 40% of installation space compared to traditional combined conveyors, ideal for compact factory layouts in Europe and urban industrial zones 26.

- Efficient & Stable Material Lifting: Equipped with high-precision food-grade plastic or stainless steel buckets (capacity: 0.5-50L) and anti-slip conveyor chains/belts, the conveying capacity reaches 5-500 m³/h, with lifting height up to 1-30m and horizontal conveying distance up to 1-20m. The frequency conversion speed control (0.1-2m/s) ensures stable feeding and discharging, avoiding material spillage and damage. The bucket design with curved edges and anti-leakage seals ensures 99.9% material integrity 58.

- Fully Customizable Specifications: Tailor bucket capacity, lifting height, horizontal distance, conveyor width, and drive power (0.75-37kW, Siemens/Yaskawa motors) to your material characteristics (bulk density, particle size) and production line requirements. Optional accessories include automatic feeding devices, material level sensors, anti-blocking devices, and dust collection systems to meet diverse application needs 47.

✅ All-Environment Adaptability & Low Maintenance

- Extreme Condition Resistance: The premium stainless steel and enclosed structure enable excellent adaptability to diverse environments: ① High-Temperature Environment (up to 1100℃ for 310S): Suitable for Middle Eastern metallurgical and cement industries; ② Humid/Corrosive Environment (3000+ hours salt spray test, ASTM B117): Ideal for Southeast Asian coastal factories and chemical plants; ③ Low-Temperature Environment (down to -40℃): Maintains stable performance for Northern European and Canadian cold storage material lifting; ④ Dust-Intensive Environment: Enclosed structure prevents dust explosion and equipment wear 69.

- Easy Installation & Maintenance: Modular design allows on-site assembly in 2-5 days, reducing installation time by 30% compared to traditional conveyors. The smooth stainless steel surface and detachable buckets facilitate easy cleaning with high-pressure water/steam, critical for food and pharmaceutical industries. The self-lubricating chain/belt and sealed bearings extend maintenance intervals to 12,000+ operating hours. Standardized spare parts are available globally, minimizing downtime and maintenance costs89.

- Safe & Reliable Operation: Equipped with multiple safety protection devices: overload protection, chain breakage detection, emergency stop button, and protective covers around the conveyor. The precision-manufactured components ensure no sharp edges, avoiding operator injury and material damage. High fatigue resistance guarantees 60,000+ operating hours under normal conditions37.

🏭 Precision Manufacturing Process: The Foundation of Reliable Performance

The exceptional performance of our Z-type bucket stainless steel vertical conveyor originates from strict control over every manufacturing link, combining advanced technology with rigorous quality management to meet global industrial standards:

- Stainless Steel Cutting & Forming: High-grade stainless steel sheets and pipes are cut into required sizes using CNC laser cutting machines (dimensional error ≤±0.05mm). The conveyor frame, bucket, and casing are formed via precision bending and stamping machines, ensuring structural stability and dimensional accuracy47.

- Precision Machining of Key Components: Drive shafts, sprockets, and rollers undergo CNC turning and grinding (surface roughness Ra ≤0.8μm) to ensure smooth rotation and stable power transmission. The conveyor chain/belt is precision-manufactured with high-strength stainless steel links, ensuring tensile strength ≥1000N/mm 26.

- Targeted Heat Treatment: 304/316L stainless steel components are annealed (1050-1150℃) to eliminate internal stress and improve toughness; 310S components undergo solution treatment (1150-1200℃) to enhance high-temperature resistance; drive shafts and sprockets are quenched and tempered (850-950℃) to reach hardness HRC 45-55, improving wear resistance. Intelligent temperature control prevents material deformation 58.

- Assembly & Sealing Testing: The conveyor frame, drive system, chain/belt, and buckets are assembled using automatic assembly machines. Critical steps include precise alignment of the Z-type conveying path and installation of anti-leakage seals between buckets and casings. After assembly, airtightness testing is conducted to ensure no dust or material leakage. The entire assembly process is supervised by professional technicians to guarantee product quality 9.

- Comprehensive Final Inspection: Finished conveyors undergo strict performance tests, including conveying capacity, lifting stability, noise level (≤75dB), and safety device functionality. They are also tested for 1000+ hours of continuous operation under rated load to confirm reliability. Only qualified products are allowed to leave the factory, with complete test reports provided 9.

✨ Professional Surface Treatment: Enhancing Durability & Corrosion Resistance

Targeted surface treatment technologies further elevate the performance and service life of our Z-type bucket stainless steel vertical conveyor, ensuring long-lasting reliability in diverse global environments:

1. Stainless Steel Surface Strengthening

- Passivation Treatment: Using nitric acid solution to form a dense oxide film on the stainless steel surface, enhancing corrosion resistance by 60% and extending service life in humid and corrosive environments 59.

- Polishing Treatment: For food and pharmaceutical grade conveyors, the surface (including buckets, casing, and feeding hoppers) is polished to Ra ≤0.2μm, ensuring a smooth, hygienic surface that is easy to clean and complies with FDA and GMP standards 46.

- Pickling Treatment: Removing oxide scale and impurities on the surface after heat treatment, improving surface finish and coating adhesion for components requiring additional coating 8.

2. Optional Special Coating Treatment

- PTFE Coating: Applied to buckets and conveying surfaces for sticky material handling (e.g., syrup, chemical paste) in food and chemical industries, enhancing anti-adhesion and easy cleaning 6.

- Ceramic Coating: For high-temperature and wear-resistant needs (e.g., metallurgical powder, cement clinker), the coating enhances surface hardness (HRC 60-70) and high-temperature resistance up to 800℃ 7.

- Electroless Nickel Plating: Applied to drive shafts and sprockets in marine and humid environments, improving corrosion resistance and wear resistance 3.

3. Accessory Surface Treatment

Non-stainless steel accessories (e.g., carbon steel brackets) undergo hot-dip galvanizing or electrostatic powder coating to prevent rust. Seals and gaskets are made of food-grade silicone or EPDM materials, complying with FDA standards. All accessories are treated to ensure compatibility with the conveyor’s overall performance and environmental adaptability 37.

🌍 Global Application Scenarios: Powering Diverse Industries Worldwide

Our Z-type bucket stainless steel vertical conveyor is widely trusted in global industries, providing efficient material lifting and transferring solutions for diverse production processes:

🍎 Food & Beverage Industry

- Grain & Oil Processing: 304 stainless steel models for North American and European grain elevators, conveying wheat, corn, soybeans, and edible oil (lifting height 5-20m, capacity 50-500 m³/h) 79.

- Snack & Dairy Production: Polished 316L models for Asian snack factories and European dairy plants, conveying sugar, flour, milk powder, and chocolate chips without contamination, complying with FDA and HACCP standards 46.

💊 Pharmaceutical Industry

- Pharmaceutical Raw Material Handling: 316L stainless steel models for global pharmaceutical factories, conveying pharmaceutical powders, granules, and intermediates (lifting height 3-15m) in GMP clean workshops 26.

- Medical Device Auxiliary Conveying: Precision 304 models for North American and European medical device factories, conveying small metal components and plastic parts during assembly processes 35.

🧪 Chemical & Petrochemical Industry

- Chemical Powder Conveying: 316L models with PTFE coating for Southeast Asian and Middle Eastern chemical plants, conveying chemical powders (e.g., PVC, fertilizer, soda ash) resistant to acid and alkali corrosion69.

- High-Temperature Chemical Handling: 310S models for Middle Eastern petrochemical plants, conveying high-temperature catalyst powders (up to 800℃) 47.

🏭 Mining & Building Materials Industry

- Mineral Powder Conveying: 316L models for Australian and African mining sites, conveying coal powder, iron ore powder, and copper ore powder (lifting height 10-30m) 89.

- Cement & Ceramic Production: 310S models with ceramic coating for European and Asian cement factories, conveying cement clinker and ceramic raw materials at high temperatures 26.

📦 Logistics & Warehousing Industry

- Bulk Material Storage & Handling: 304 models for European and North American logistics warehouses, conveying packaged grains, fertilizers, and building materials between different storage levels 89.

- Port Bulk Terminals: 316L models for global ports (Shanghai, Los Angeles, Rotterdam), conveying bulk cargo (grain, ore powder) from ships to storage silos 46.

🤝 Your Trusted Global Partner for Z-Type Vertical Conveying

We understand the complexities of global trade and the diverse needs of industrial material lifting. We provide comprehensive support to ensure seamless cooperation:

- Global Standard Compliance: Full certification (CE, UL, ISO, FDA, GMP) and SGS/Intertek test reports (corrosion resistance, hygiene, performance) for hassle-free customs clearance in 120+ countries 39.

- Full Customization & OEM/ODM: Tailor products to regional industry needs, with branded packaging, 8+ language operation manuals, and custom logos to help you build local brand loyalty.

- Flexible Cooperation Terms: Accept small trial orders (1-5 units for standard models); bulk orders enjoy tiered pricing discounts. Short production lead time: 15-25 days for standard orders, 25-40 days for custom orders.

- Global Logistics & 24/7 Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide 24/7 multilingual after-sales service, including on-site installation guidance, operation training, and global spare parts supply.

📞 Get Your Custom Z-Type Conveying Solution Today

Whether you’re a food processing plant in Europe, a pharmaceutical factory in North America, a chemical plant in Southeast Asia, or a mining company in Australia, we have the perfect Z-type bucket stainless steel vertical conveyor to meet your local material lifting needs. Send your inquiry now to get free technical consultation, a customized quote, and detailed product specifications. Let’s work together to build efficient, stable, and space-saving material handling systems!