Stainless Steel Woven Wire Mesh Conveyor Belt: High-Temp Resistant, Corrosion-Proof for Global Industrial Conveying

When global industries seek reliable conveying solutions for high-temperature, corrosive, or hygiene-critical scenarios—such as food processing, metallurgy, chemical engineering, and electronics manufacturing—our Stainless Steel Woven Wire Mesh Conveyor Belt emerges as the first choice. Combining the exceptional heat resistance, corrosion resistance, and structural stability of premium stainless steel with the unique permeability and smooth conveying performance of woven mesh design, this belt excels in harsh industrial environments where ordinary conveyors fail. Unlike solid conveyor belts prone to poor heat dissipation, material accumulation, and corrosion damage, our product is custom-engineered to meet the stringent requirements of 120+ countries across North America, Europe, Asia-Pacific, Africa, and South America. Trusted by top enterprises worldwide, it’s not just a conveying component; it’s a durable, low-maintenance investment that optimizes your core production processes.

🌟 Core Features: Why It’s a Global Favorite for Harsh Environment Conveying

Every detail of our stainless steel woven wire mesh conveyor belt is designed to solve key pain points in global industrial conveying—from high-temperature stability and corrosion resistance to easy maintenance and gentle material handling. It delivers consistent, reliable performance in the most challenging conditions:

✅ Premium Stainless Steel Material & Global Standard Compliance

- Grade-Specific Material Selection: We use high-quality 304/316L/310S stainless steel wires, with wire diameters ranging from 0.8mm to 4.0mm and mesh sizes from 1mm×1mm to 50mm×50mm. 304 stainless steel balances cost-effectiveness and corrosion resistance, ideal for European and Asia-Pacific food processing and light industrial applications; 316L offers enhanced resistance to acids, alkalis, salt spray, and chloride (perfect for North American and Southeast Asian chemical plants, marine environments, and pharmaceutical industries, complying with EU FDA & US NSF standards); 310S withstands continuous high temperatures up to 1100℃ (suitable for Middle Eastern and African metallurgical, ceramic, and glass industries) 13.

- Comprehensive Global Certifications: All conveyor belts pass strict quality inspections, meeting EU CE, US UL, ISO 9001, ISO 14001, EU EN 10088, and US ASTM A240 standards. Food-grade models fully comply with FDA 21 CFR Part 177 and GMP Class 100,000 standards, while high-temperature models meet ASTM E2164 heat resistance requirements. These certifications ensure hassle-free customs clearance and market access worldwide 25.

- Hygienic & Easy to Clean: The open woven mesh structure enables thorough cleaning—residues, dust, and liquids can be easily removed with high-pressure water, steam, or air blowing, eliminating material accumulation and bacterial growth. This makes it indispensable for food, pharmaceutical, and electronic industries with strict hygiene requirements 46.

✅ Innovative Woven Mesh Design & Excellent Conveying Performance

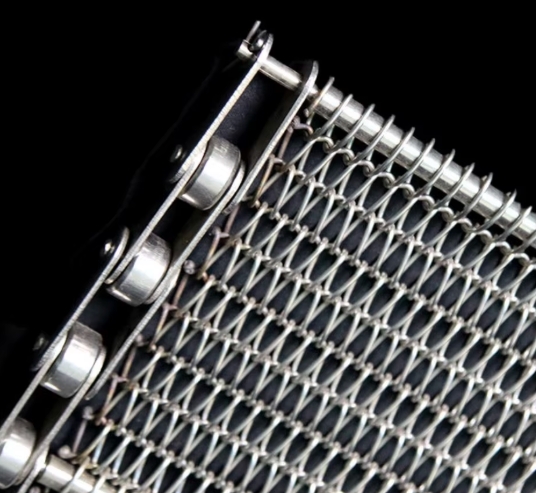

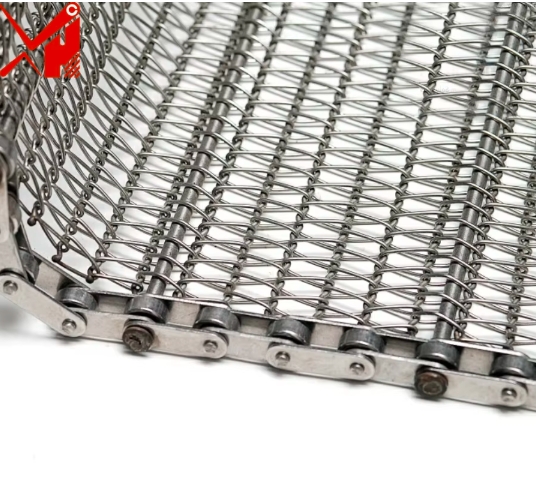

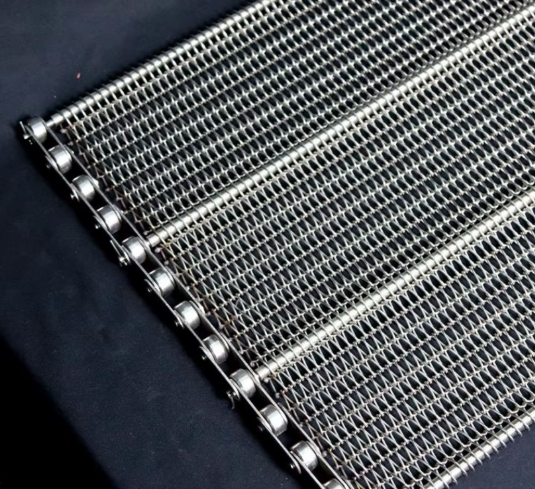

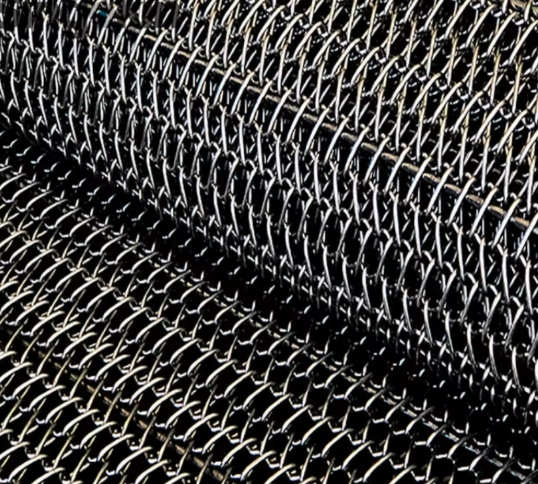

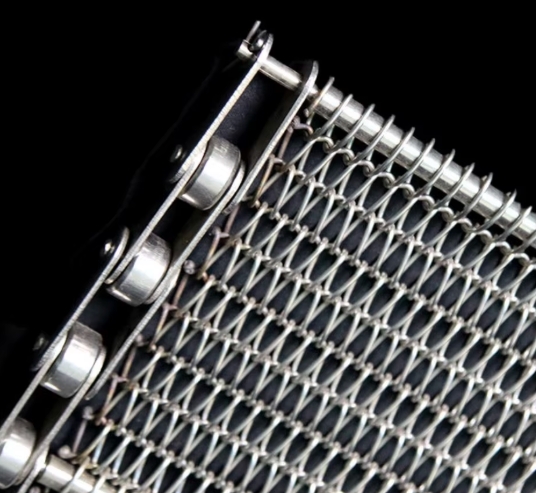

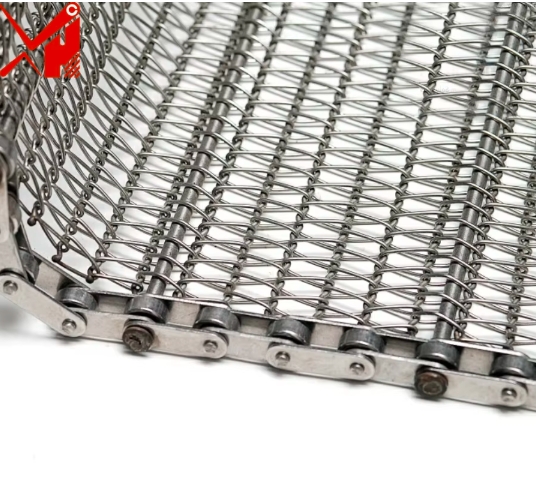

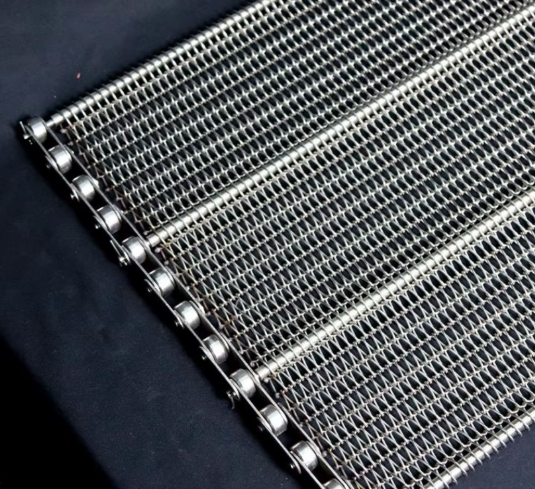

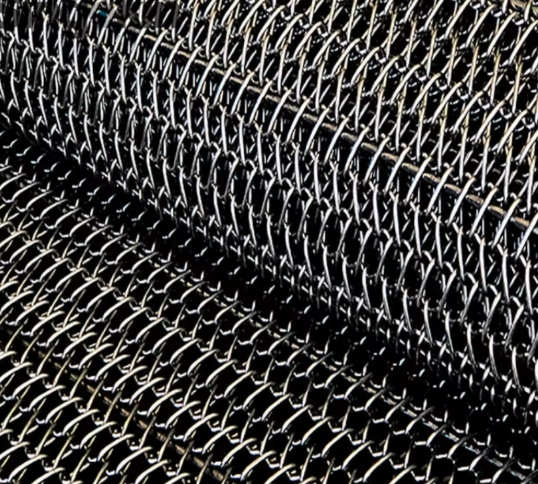

- Woven Mesh Structure Advantages: The belt is woven by computer-controlled precision looms (plain weave, twill weave, or Dutch weave) to ensure uniform mesh size and stable structure. With an open area ratio of 30%-80%, it enables excellent heat dissipation, air circulation, and liquid drainage—ideal for drying, cooling, and cooking processes. The smooth wire surface ensures gentle conveying, avoiding scratches or damage to delicate products (e.g., electronic components, fruits) 26.

- Efficient & Stable Conveying: Equipped with high-precision stainless steel sprockets and Siemens/Yaskawa drive motors (0.37-37kW), the conveying speed is adjustable (0.1-5m/s) via frequency conversion. The adjustable belt tension ensures smooth operation without deviation. Conveying capacity ranges from 0.5-100 m³/h, with belt width customizable from 300mm to 3000mm and length from 2m to 100m, adapting to diverse production line requirements 58.

- Fully Customizable Specifications: Tailor wire diameter, mesh size, weave type, belt width/length, and accessories (side guards, guide strips, anti-slip coatings, material detectors) to your material characteristics (particle size, weight, fragility) and production processes (high-temperature cooking, corrosion-resistant conveying, precision screening). Optional reinforced edges (folded or welded) enhance belt durability 47.

✅ All-Environment Adaptability & Long Service Life

- Extreme Condition Resistance: Premium stainless steel and woven structure ensure excellent adaptability to harsh environments: ① High-Temperature (up to 1100℃ for 310S): Suitable for Middle Eastern metallurgical and glass factories; ② Humid/Corrosive (5000+ hours salt spray test, ASTM B117): Ideal for Southeast Asian coastal factories and chemical plants; ③ Low-Temperature (down to -40℃): Maintains flexibility for Northern European and Canadian cold storage; ④ Abrasive: High-hardness stainless steel wires (HRC 45-55) resist wear from granular materials 69.

- Low Maintenance & Longevity: Corrosion-resistant and wear-resistant stainless steel ensures a service life of 5-10 years (3x longer than rubber belts) under normal operation. The simple structure and smooth surface minimize maintenance—only regular tension adjustment and cleaning are needed. Standardized spare parts (sprockets, wires, connectors) are available globally, reducing downtime and costs 89.

- Safe & Reliable Operation: Equipped with multiple safety devices: overload protection, belt deviation detection, emergency stop buttons, and protective covers. The stainless steel is non-toxic, flame-retardant (UL 94 V-0), and anti-static (surface resistance 10⁶-10⁹Ω), avoiding dust explosions and static damage. Precision-woven wires have no sharp edges, ensuring operator and production safety 37.

🏭 Precision Manufacturing Process: The Basis of Reliability

The outstanding performance of our stainless steel woven wire mesh conveyor belt comes from strict control over every manufacturing link, combining advanced weaving technology with rigorous quality management to meet global industrial standards:

- Stainless Steel Wire Preparation: High-grade stainless steel ingots are drawn into precise-diameter wires (error ≤±0.01mm) via multi-pass drawing machines. The wires are annealed (1050-1150℃) to eliminate internal stress, improve flexibility and tensile strength. Surface cleaning removes oil and impurities to ensure weaving quality47.

- Precision Mesh Weaving: Processed stainless steel wires are woven into mesh by computer-controlled precision looms. Weave types are selected based on applications: ① Plain weave for general conveying (uniform mesh, good air permeability); ② Twill weave for high-load conveying (higher tensile strength); ③ Dutch weave for precision screening (small mesh, high filtering accuracy). Weaving precision ensures mesh size error ≤±0.05mm 26.

- Belt Forming & Edge Reinforcement: Woven mesh is cut into required sizes by CNC cutting machines. Edge reinforcement prevents fraying—options include folded edges (welded or sewn) and reinforced steel strips (welded to edges). The mesh is then connected to drive chains or sprocket holes via precision argon arc welding to form a complete conveyor belt 58.

- Heat Treatment & Surface Finishing: Formed belts undergo targeted heat treatment: 304/316L belts are annealed to eliminate welding stress; 310S belts undergo solution treatment to enhance high-temperature resistance. Surface finishing (polishing, passivation) is performed as needed to improve corrosion resistance and smoothness 9.

- Comprehensive Final Inspection: Finished belts undergo strict performance tests (tensile strength, mesh accuracy, welding firmness, corrosion resistance, high-temperature resistance) and 2000+ hours of continuous operation under rated load. Only qualified products leave the factory with complete test reports 9.

✨ Professional Surface Treatment: Enhance Durability & Functionality

Targeted surface treatment further improves the performance and service life of our stainless steel woven wire mesh conveyor belt, ensuring long-term reliability in diverse global environments:

1. Stainless Steel Mesh Surface Treatment

- Passivation Treatment: Nitric acid or citric acid solution forms a dense oxide film on the mesh surface, increasing corrosion resistance by 60% and extending service life in humid/corrosive environments 59.

- Polishing Treatment: For food, pharmaceutical, and electronic industries, the mesh surface is polished to Ra ≤0.2μm, ensuring a smooth, hygienic surface that avoids material adhesion and scratches, while improving aesthetics 46.

- Pickling Treatment: Removes oxide scale and welding residues after heat treatment and welding, improving surface finish and corrosion resistance 8.

2. Optional Functional Coating Treatment

- PTFE Coating: Applied to mesh surfaces for food and chemical industries, enhancing anti-adhesion (prevents sticky material buildup) and corrosion resistance (resists acids, alkalis, organic solvents). Withstands temperatures up to 260℃6.

- Ceramic Coating: For high-temperature and abrasive environments (e.g., metallurgy, mining), enhances surface hardness (HRC 60-70) and wear resistance, extending service life by 2-3 times 7.

- Anti-Static Coating: For electronic components and flammable materials, achieves surface resistance 10⁶-10⁹Ω, complying with ANSI/ESD S20.20 standards to avoid static damage 3.

3. Accessory Surface Treatment

Stainless steel accessories (sprockets, guides, side guards) undergo passivation or polishing to match the belt’s corrosion resistance. Carbon steel accessories (drive shafts, brackets) undergo hot-dip galvanizing or electrostatic powder coating to prevent rust, ensuring seamless cooperation with the belt and long-term stable operation 37.

🌍 Global Application Scenarios: Powering Diverse Industries

Our stainless steel woven wire mesh conveyor belt is widely trusted by global industries, providing reliable conveying solutions for harsh and demanding production processes:

🍎 Food & Beverage Industry

- Food Processing & Cooking: 304/316L polished mesh models for European and Asian food factories, used in baking (bread, cookies), frying (chips, French fries), and drying (fruits, vegetables). The open mesh ensures uniform heating and easy oil/dust removal, complying with FDA and HACCP standards 79.

- Dairy & Pharmaceutical Processing: 316L passivated mesh models for North American dairy and pharmaceutical plants, conveying milk powder, pharmaceutical powders, and capsules. The hygienic surface and easy cleaning meet GMP requirements 46.

🏭 Metallurgy & Heat Treatment Industry

- High-Temperature Heat Treatment: 310S mesh models for Middle Eastern and European metallurgical plants, conveying metal parts, steel strips, and castings during annealing, quenching, and sintering (withstanding up to 1100℃) 26.

- Metal Powder Screening: Dutch weave mesh models for Australian and African mining sites, conveying and screening metal powders (iron ore, copper ore) with high precision 35.

🧪 Chemical & Petrochemical Industry

- Chemical Material Conveying: 316L mesh with PTFE coating for Southeast Asian and North American chemical plants, conveying chemical powders, granules, and corrosive materials (resisting acids, alkalis, organic solvents) 69.

- Wastewater Treatment: Plain weave mesh models for global wastewater treatment plants, filtering and conveying sludge and solid particles 47.

📱 Electronic & Electrical Industry

- Electronic Component Processing: 304 polished mesh models for Asian electronic factories, conveying chips, circuit boards, and accessories during cleaning, drying, and assembly. The smooth surface avoids scratches, and anti-static coating prevents static damage 89.

- Battery Production: 316L mesh models for global battery manufacturers, conveying electrodes and components during high-temperature drying 26.

🏭 Glass & Ceramic Industry

- Glass & Ceramic Firing: 310S mesh models for European and Asian glass/ceramic factories, conveying glass sheets, ceramic tiles, and greenware during high-temperature firing (withstanding up to 1000℃) 89.

- Raw Material Screening: Twill weave mesh models for Middle Eastern ceramic plants, conveying and screening raw materials (clay, feldspar) for uniform particle size 46.

🤝 Your Trusted Global Partner for Industrial Conveying

We understand the complexities of global trade and the rigorous requirements of industrial conveying. We provide comprehensive support for seamless cooperation:

- Global Standard Compliance: Full certifications (CE, UL, ISO, FDA, GMP) and SGS/Intertek test reports (corrosion resistance, heat resistance, hygiene, tensile strength) for hassle-free customs clearance in 120+ countries 39.

- Full Customization & OEM/ODM: Tailor wire diameter, mesh size, weave type, belt size, and surface treatment to regional needs. Provide branded packaging, 8+ language manuals, and custom logos to build local brand loyalty.

- Flexible Cooperation Terms: Accept small trial orders (1-5 meters for standard models); bulk orders enjoy tiered discounts. Short lead times: 15-25 days for standard orders, 25-40 days for custom high-temperature/corrosion-resistant models.

- Global Logistics & 24/7 Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide 24/7 multilingual after-sales service, including on-site installation guidance, operation training, and global spare parts supply.

📞 Get Your Custom Conveying Solution Today

Whether you’re a food processing plant in Europe, a metallurgical factory in the Middle East, a chemical plant in Southeast Asia, or an electronic factory in Asia, we have the perfect stainless steel woven wire mesh conveyor belt for your local needs. Send your inquiry now for free technical consultation, a customized quote, and detailed product specifications. Let’s build efficient, stable, and long-lasting material handling systems together!