Stainless Steel Flat Trapezoidal Mesh Belt Conveyor: High-Strength, Hygienic & Versatile for Global Industries

Stainless steel flat trapezoidal mesh belt conveyor, a specialized material handling equipment featuring a unique trapezoidal mesh structure and premium stainless steel construction, integrates the advantages of stable conveying, excellent ventilation, and strong corrosion resistance. It is globally recognized as a core component in automated production lines, especially for scenarios requiring hygiene, high temperature resistance, and long-term stable operation. Traditional conveyor belts often struggle with poor mesh stability, easy material jamming, and insufficient corrosion resistance in harsh environments, leading to frequent maintenance and reduced production efficiency. Our stainless steel flat trapezoidal mesh belt conveyor is engineered with high-grade stainless steel materials, precision trapezoidal mesh weaving technology, and global industrial standard compliance, tailored to the diverse needs of 120+ countries across North America, Europe, Asia-Pacific, Africa, and South America. Trusted by food processing, pharmaceutical, chemical, and automotive industries worldwide, it’s the reliable choice for high-efficiency, low-maintenance, and hygienic material handling solutions.

🌍 What Makes Our Stainless Steel Flat Trapezoidal Mesh Belt Conveyor Globally Preferred?

We don’t just produce stainless steel flat trapezoidal mesh belt conveyors—we optimize trapezoidal mesh structure design, stainless steel material selection, manufacturing precision, and surface treatment to adapt to diverse global industrial environments, from European food-grade clean workshops and North American pharmaceutical factories to Southeast Asian humid chemical plants and Middle Eastern high-temperature smelting sites. Every feature is designed to solve mesh instability, material jamming, corrosion, and hygiene pain points, ensuring consistent performance in complex scenarios:

✅ Premium Stainless Steel Material & Global Standard Compliance

- High-Grade Stainless Steel Selection: We adopt 304/316L/310S stainless steel as the core material to meet diverse environmental needs: ① 304 Stainless Steel: Excellent corrosion resistance and cost-effectiveness, suitable for general food processing and logistics industries in Europe and Asia-Pacific; ② 316L Stainless Steel: Enhanced resistance to acids, alkalis, and salt spray, ideal for chemical, pharmaceutical, and coastal applications in North America and Southeast Asia, complying with EU FDA and US NSF standards; ③ 310S Stainless Steel: High-temperature resistance up to 1100℃, suitable for smelting, drying, and heat treatment processes in Middle Eastern and African industrial plants 13.

- Strict Global Standard Adherence: All conveyors pass rigorous quality inspections, complying with EU CE, US UL, ISO 9001, and FDA 21 CFR Part 177 standards. The stainless steel materials meet EU EN 10088 and US ASTM A240 standards, ensuring hassle-free customs clearance and market access in 120+ countries. Food-grade models fully comply with GMP requirements, making them suitable for high-hygiene industries25.

- Hygienic & Environmental Protection: The stainless steel material is non-toxic, tasteless, and free of heavy metals (lead, cadmium ≤0.001%), ensuring no contamination of conveyed materials. The trapezoidal mesh structure is easy to clean, avoiding dead corners for bacteria accumulation. Our production processes adopt environmentally friendly technologies, complying with EU RoHS standards, and all materials are 100% recyclable, meeting global green production requirements 46.

✅ Unique Trapezoidal Mesh Structure & Excellent Conveying Performance

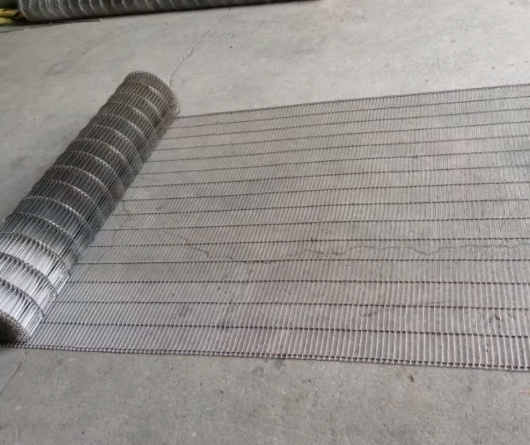

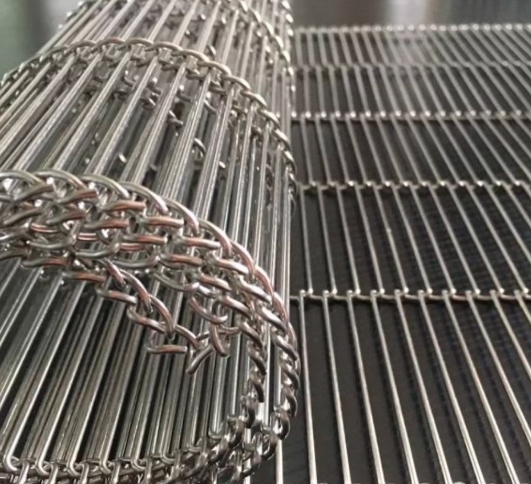

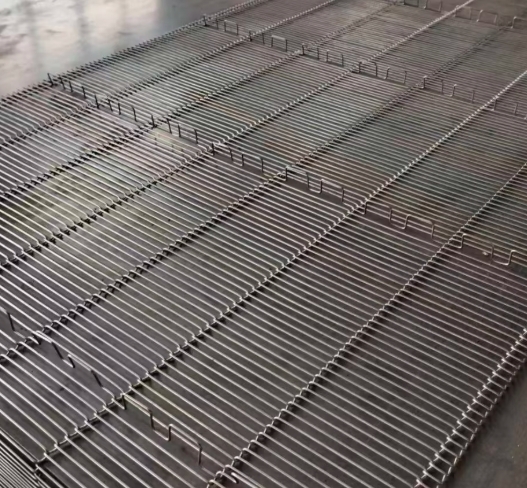

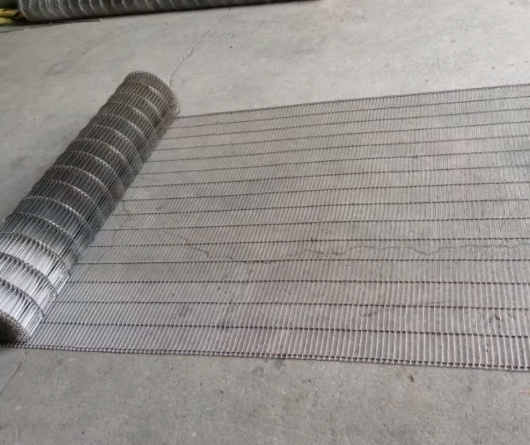

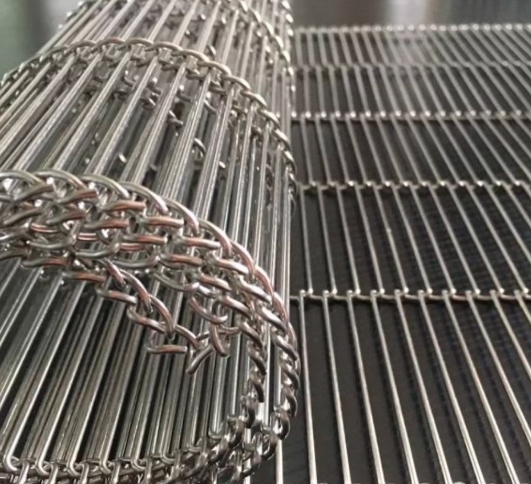

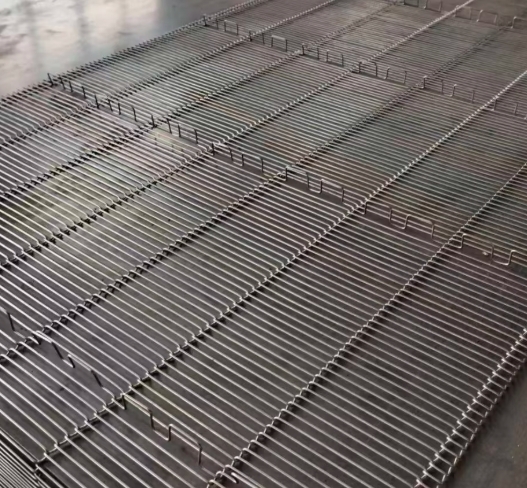

- Stable Trapezoidal Mesh Design: The unique trapezoidal mesh structure (wire diameter: 1.0-5.0mm, mesh size: 5×10-50×100mm) features strong tensile resistance and load-bearing capacity (up to 300kg/m). The flat mesh surface ensures smooth material conveying without jamming, suitable for granular, powdery, block, and packaged materials. The trapezoidal holes enhance ventilation and drainage, making it ideal for washing, blanching, and drying processes 26.

- Efficient & Adjustable Conveying: Equipped with high-efficiency Siemens/Yaskawa gear motors, the conveying speed can be adjusted from 0.1-3m/s via frequency conversion technology, matching different production line rhythms. The adjustable conveying angle (0-25°) supports horizontal and inclined conveying, maximizing space utilization. The conveying efficiency reaches 5-300m³/h, significantly improving production efficiency 58.

- Customizable Specifications: Support customization of mesh belt width (500-2000mm), length (2-50m), wire diameter, and mesh size according to customer production line layout and material characteristics. Optional accessories include side baffles, guide rails, scrapers, and metal detectors, adapting to diverse material handling needs47.

✅ All-Environment Adaptability & Easy Maintenance

- Extreme Environment Resistance: The stainless steel material and trapezoidal mesh structure enable excellent adaptability to extreme conditions: ① High-Temperature Environment (up to 1100℃ for 310S stainless steel): Suitable for smelting and drying processes in the Middle East and Africa; ② Humid/Corrosive Environment: 316L stainless steel resists acid, alkali, and salt spray corrosion (2000+ hours salt spray test, ASTM B117), suitable for coastal logistics and chemical plants in Southeast Asia; ③ Low-Temperature Environment (down to -40℃): Maintains flexibility without brittle fracture, suitable for cold storage logistics in Northern Europe and Canada 69.

- Easy Installation & Maintenance: The modular design facilitates on-site installation and disassembly, reducing installation time by 30% compared to traditional conveyors. The trapezoidal mesh belt is easy to clean with water or steam, requiring no special maintenance. Standardized spare parts are available globally, reducing maintenance costs and downtime 89.

- Safe & Reliable Operation: Equipped with multiple safety protection devices, including emergency stop buttons, anti-deviation sensors, overload protection, and safety guards, ensuring operator safety. The smooth trapezoidal mesh surface avoids material damage and operator scratches 37.

🏭 Core Manufacturing Process & Professional Surface Treatment

The excellent performance of our stainless steel flat trapezoidal mesh belt conveyor originates from sophisticated core manufacturing processes and targeted professional surface treatment technologies. We strictly control every link from stainless steel wire drawing to finished conveyor assembly, ensuring each product meets global industrial quality standards. Below is a detailed breakdown:

1. Core Manufacturing Processes: Precision-Driven from Wire to Conveyor

- Stainless Steel Wire Drawing & Straightening: High-grade stainless steel ingots are drawn into wires of required diameters (error ≤±0.05mm) using precision wire drawing machines. The drawn wires are straightened by automatic straightening machines to ensure uniform wire diameter and straightness, laying a foundation for stable mesh weaving 47.

- Precision Trapezoidal Mesh Weaving: Adopt automatic CNC weaving machines to weave the straightened stainless steel wires into trapezoidal mesh. The weaving process is intelligently controlled, ensuring uniform mesh size, tight wire connection, and flat mesh surface. The trapezoidal mesh structure is reinforced by interlocking wires, enhancing tensile strength and load-bearing capacity. The mesh is cut into required widths and lengths with dimensional error ≤±1mm 26.

- Mesh Belt Edge Reinforcement & Sprocket Installation: The edges of the trapezoidal mesh belt are reinforced by welding or folding to avoid fraying. High-strength sprockets (stainless steel or carbon steel with galvanizing treatment) are installed at both ends of the mesh belt to ensure smooth power transmission. The sprocket and mesh belt are precisely matched to avoid slipping during operation 58.

- Conveyor Assembly & Debugging: The trapezoidal mesh belt is assembled with the frame, motor, reducer, and control system. Professional technicians conduct comprehensive debugging, including speed test, deviation test, load test, and safety protection test. The conveyor undergoes a 72-hour continuous operation test under rated load to ensure stable operation, and only qualified products are allowed to leave the factory 9.

2. Professional Surface Treatment: Enhancing Corrosion Resistance & Hygiene

- Stainless Steel Mesh Belt Surface Treatment: ① Passivation Treatment: Use nitric acid solution to form a dense oxide film on the mesh belt surface, enhancing corrosion resistance and extending service life; ② Polishing Treatment: For food-grade and pharmaceutical-grade conveyors, the mesh belt surface is polished to Ra ≤0.2μm, ensuring a smooth, hygienic surface that is easy to clean and complies with FDA and GMP standards; ③ Pickling Treatment: Remove oxide scale and impurities on the mesh surface, improving surface finish and corrosion resistance 59.

- Frame & Metal Component Surface Treatment: The frame (304/316L stainless steel) undergoes passivation and polishing treatment. For carbon steel accessories (if any), hot-dip galvanizing or electrostatic powder coating is adopted to enhance corrosion resistance. All metal components are free of sharp edges, ensuring safe operation and compliance with global safety standards 68.

- Electrical Component Protection: Electrical components (motor, PLC, sensor) are selected with IP54-IP65 protection ratings according to the working environment. The junction box and wiring harness are equipped with waterproof and dustproof covers, and wiring terminals are treated with anti-oxidation, ensuring stable operation in harsh environments 37.

3. Strict Quality Control: Guarding Every Process

- Raw Material & Component Inspection: Each batch of stainless steel wires is tested for chemical composition (spectrometer) and mechanical properties (tensile strength tester). Core components (motor, reducer, PLC) are purchased from authorized suppliers, with strict incoming inspection and certificate verification 37.

- In-Process Quality Supervision: During wire drawing and weaving, real-time inspections of wire diameter, mesh size, and mesh flatness are conducted. During assembly and debugging, inspections of assembly accuracy, electrical connection reliability, and operation stability are performed. All inspection data is recorded and traceable 68.

- Final Performance Testing: Finished conveyors undergo comprehensive performance tests, including tensile strength, load-bearing capacity, corrosion resistance (salt spray test, ASTM B117), high-temperature resistance, and hygiene performance. A 2% random sampling method is adopted for each batch, and complete SGS/Intertek test reports are provided for bulk orders 9.

🌍 Global Application Scenarios: Covering Diverse High-Demand Industries

Our stainless steel flat trapezoidal mesh belt conveyor is widely used in global food processing, pharmaceutical, chemical, automotive, and other high-demand industries, providing efficient and stable material handling solutions for various production processes:

🍎 Food & Beverage Industry

- Food Processing Lines: 304/316L stainless steel conveyors for European and North American food processing plants (fruit, vegetable, meat, seafood, dairy, bakery). The hygienic, polished mesh belt is easy to clean, complying with FDA standards. Suitable for washing, blanching, drying, and packaging processes, the trapezoidal mesh ensures good ventilation and drainage79.

- Beverage Production Lines: 316L stainless steel conveyors for Asian and European beverage factories. Used for conveying bottles, cans, and beverage raw materials, the corrosion-resistant mesh belt adapts to the humid production environment 35.

💊 Pharmaceutical Industry

- Pharmaceutical Production Lines: 316L stainless steel conveyors with polished surfaces for global pharmaceutical factories. Used for conveying pharmaceutical raw materials, intermediates, and finished products, ensuring no contamination and complying with GMP Class 100,000 standards. Suitable for drying, granulating, and packaging processes 46.

- Medical Device Conveying: Precision trapezoidal mesh belt conveyors for North American and European medical device factories. Used for conveying medical devices during assembly and sterilization processes, the stable mesh structure ensures no damage to delicate components 28.

🧪 Chemical & Petrochemical Industry

- Chemical Raw Material Conveying: 316L stainless steel conveyors for Southeast Asian and Middle Eastern chemical plants. Resists corrosion from acids, alkalis, and organic solvents, suitable for conveying chemical powders, granules, and intermediates 69.

- High-Temperature Chemical Processes: 310S stainless steel conveyors for Middle Eastern petrochemical plants. Used for conveying high-temperature chemical products and catalysts, withstanding temperatures up to 1100℃ 47.

🚗 Automotive & Electronic Industry

- Automotive Parts Heat Treatment: 310S stainless steel conveyors for global automotive manufacturers (BMW, Toyota, Ford). Used for conveying auto parts during heat treatment processes, the high-temperature resistant mesh belt ensures stable operation 26.

- Electronic Component Conveying: Anti-static polished stainless steel conveyors for Asian electronic component factories. Used for conveying chips and circuit boards, the anti-static mesh surface avoids electrostatic damage to components35.

🏭 Other Industrial Fields

- Mining & Metallurgy: 316L stainless steel conveyors for Australian and African mining sites. Used for conveying ore and metal particles, the wear-resistant trapezoidal mesh belt adapts to harsh mining environments 89.

- Logistics & Warehousing: 304 stainless steel conveyors for European and North American logistics warehouses. Used for conveying packaged goods, the flat mesh surface ensures smooth conveying without jamming 46.

🌍 Your Trusted Global Stainless Steel Flat Trapezoidal Mesh Belt Conveyor Partner

We understand the complexities of global trade and the high requirements of stainless steel flat trapezoidal mesh belt conveyors in diverse high-demand industries. We provide comprehensive support to ensure smooth cooperation:

- Global Standard Compliance: Passes CE, UL, ISO 9001, FDA, and GMP standards. Provides complete SGS/Intertek test reports (corrosion resistance, hygiene, high-temperature resistance) for hassle-free customs clearance in 120+ countries 39.

- Full Customization Service: Tailor mesh belt width, length, wire diameter, mesh size, surface treatment (polishing/passivation), and control system to regional industrial needs. Support OEM/ODM with branded packaging, multilingual (8+ languages) operation manuals, and custom logos to help you build local brand loyalty.

- Flexible Cooperation Terms: Accept small trial orders (1-5 units for standard models) for new partners; bulk orders enjoy tiered pricing discounts. Short production lead time: 15-25 days for standard orders, 25-40 days for custom orders.

- Efficient Logistics & Multilingual Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide 24/7 after-sales service in 8+ languages, including on-site installation guidance, operation training, and global spare parts supply.

📞 Get Your Custom Solution Today

Whether you’re a food processing plant in Europe, a pharmaceutical factory in North America, a chemical plant in Southeast Asia, or an automotive manufacturer globally, we have the perfect stainless steel flat trapezoidal mesh belt conveyor to meet your local industrial needs. Send your inquiry now to get free technical consultation, a customized quote, and detailed product specifications. Let’s work together to build efficient, hygienic, and stable automated material handling systems!