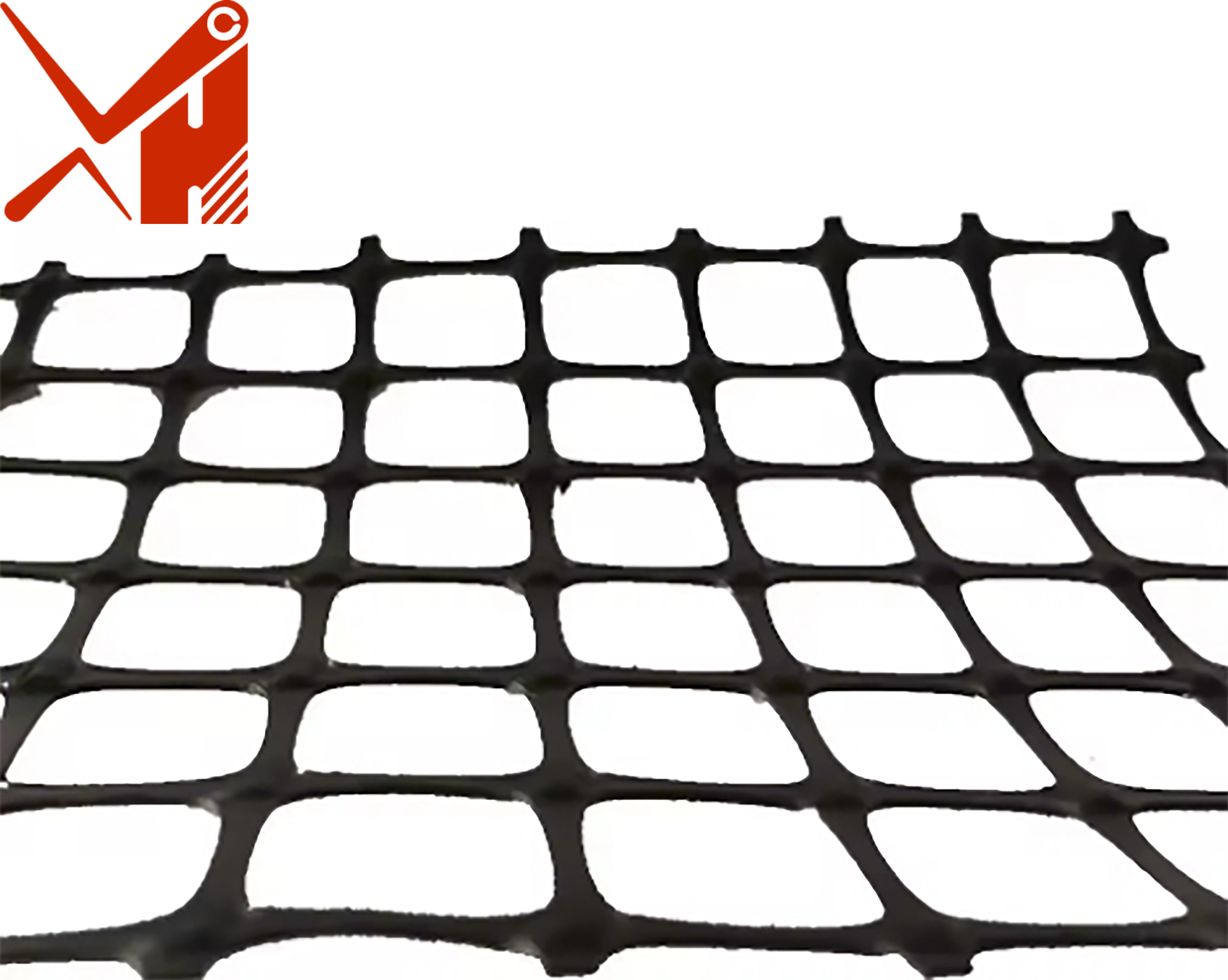

Premium Plastic Grille: Versatile Global Solution for Construction, Agriculture & Industry

Plastic grille, as a high-performance alternative to traditional metal, wood, and concrete grilles, has become a staple in global construction, agriculture, transportation, and industrial sectors. Poor-quality grilles often suffer from issues like easy corrosion, heavy weight, high maintenance costs, and environmental non-compliance. Our premium plastic grille offers alightweight, durable, eco-friendly, and region-adapted solution, trusted by distributors, contractors, and end-users in 120+ countries across North America, Europe, Asia-Pacific, Africa, and South America.

🌍 Why Our Plastic Grille Dominates Global Markets

We tailor our plastic grille to the unique climate conditions, industry standards, and application needs of different regions, integrating high-quality materials and advanced craftsmanship. Here are the core features that win global recognition:

✅ Superior Material & All-Weather Durability

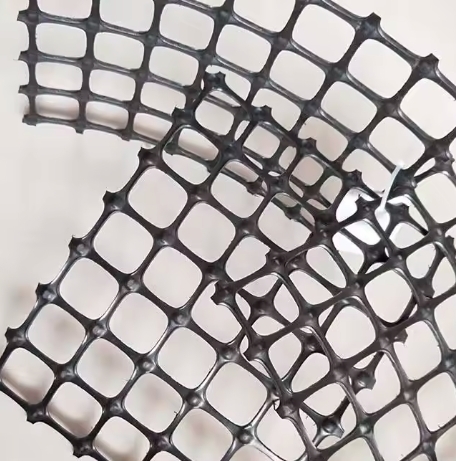

- High-Grade Raw Materials: Mainly adopts 100% virgin HDPE, PP, and PVC resins, with optional fiberglass-reinforced plastic (FRP) for high-strength scenarios. HDPE/PP grilles balance cost-effectiveness and toughness; PVC grilles offer excellent waterproof and flame-retardant performance; FRP grilles boast ultra-high load-bearing capacity. All materials are non-toxic, odorless, recyclable, and comply with EU REACH, US FDA, and RoHS standards, safe for food contact and environmental protection 13.

- Extreme Environment Resistance: Added with 3-5% UV stabilizers and anti-aging agents, the grille can withstand 6000+ hours of strong sunlight exposure, suitable for high-sunlight regions like Africa, the Middle East, and North America. It resists extreme temperatures (-40℃ to 90℃), heavy rain, frost, salt spray corrosion, and chemical erosion (acid, alkali), with a service life of 5-10 years — 2-3 times longer than metal and wood grilles 24.

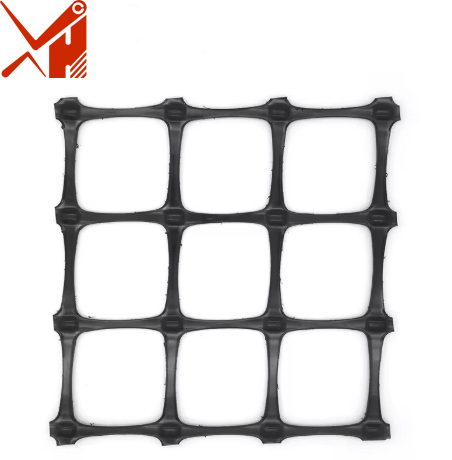

- Lightweight & High Load-Bearing: Weighs only 1/3 of steel and 1/2 of concrete, easy to transport, hoist, and install — reducing transportation and labor costs by 40%. Despite its lightweight, it has excellent tensile strength (20-50MPa) and load-bearing capacity (10-50kN/m²), meeting global industrial and construction standards. For example, our HDPE grille can bear 30kN/m², suitable for pedestrian walkways and light vehicle passage 46.

✅ Precision Design for Versatile Global Needs

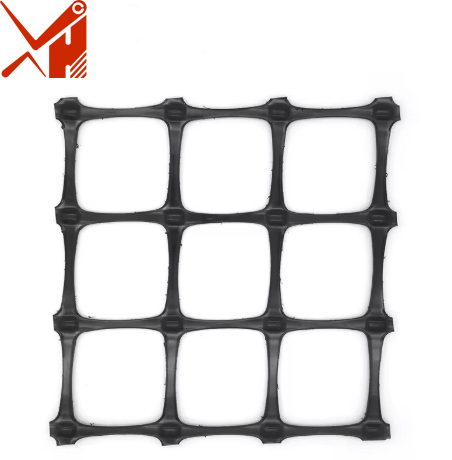

- Customizable Specifications: Support full customization of structure (honeycomb, grid, perforated), grille size (thickness 5mm-50mm, width 1m-1.5m, length 2m-6m), and grid spacing (10mm×10mm to 100mm×100mm). For example: ① Fine grid (10×10mm) FRP grille for European chemical plant platforms; ② Medium grid (30×30mm) HDPE grille for North American agricultural drainage channels; ③ Large grid (50×50mm) PP grille for African livestock pens 15.

- Anti-Slip & Safety Design: Surface options include embossed, grit-coated, and serrated anti-slip designs, with a friction coefficient ≥0.8 — ensuring safety in wet, oily, or icy environments (critical for European industrial platforms and North American outdoor walkways). Edge reinforcement design prevents cracking and deformation, enhancing overall structural stability 67.

- Easy Installation & Maintenance: Lightweight design allows manual installation without heavy machinery; standard sizes and pre-drilled holes facilitate quick assembly. The grille is stain-resistant, easy to clean with water or detergent, and requires no painting or anti-rust treatment — reducing long-term maintenance costs to almost zero 68.

✅ Multi-Functional & Eco-Friendly Advantages

- Excellent Drainage & Ventilation: Open grid structure ensures 60-80% drainage and ventilation rate, ideal for drainage channels, platform floors, and agricultural greenhouses. It prevents water accumulation, reduces humidity, and avoids mold and corrosion of underlying structures 15.

- Sound & Vibration Insulation: Compared to metal grilles, our plastic grille reduces noise by 30% and vibration by 25%, suitable for European residential areas, transportation hubs, and industrial workshops requiring low noise levels 7.

- Eco-Friendly & Sustainable: Recyclable materials and low-carbon production processes comply with global environmental trends. It can replace scarce wood and high-energy-consuming metal, helping customers achieve carbon reduction goals and meet EU EPD (Environmental Product Declaration) requirements 39.

🏭 Advanced Manufacturing Process & Professional Surface Treatment

The excellent performance of our plastic grille originates from mature manufacturing processes and targeted surface treatment technologies, tailored to global market needs and quality standards.

1. Core Manufacturing Processes

- Extrusion Molding Process: Main process for HDPE/PP grid grilles. Adopt twin-screw extruders to melt raw materials at 180-220℃, extrude through precision molds, and cool and shape via circulating water. This process ensures uniform material distribution and stable structure, suitable for mass production of standard-size grilles (output 200-300kg/h, defective rate ≤0.5%). Optimized for African agricultural and Asian construction grilles 4.

- Compression Molding Process: Used for FRP and thickened PVC grilles (thickness ≥20mm). Mix resin and fiber materials, then compress and cure at 120-150℃ and high pressure (15-25MPa). The process enhances material density and load-bearing capacity, making the grille suitable for high-strength scenarios (European chemical plants, North American heavy-duty platforms). Mold service life ≥100,000 shots, ensuring consistent quality for bulk orders 6.

- Thermoforming & Cutting Process: For custom-shaped grilles (e.g., curved, irregular sizes for Asian architectural decorations). Heat plastic sheets to softening temperature, then form via molds, and cut with CNC precision cutting machines (error ≤±2mm). This process supports small-batch personalized orders and complex shape requirements 5.

2. Targeted Surface Treatment Technologies

- UV-Resistant Coating: Core treatment for high-sunlight regions. Spray acrylic UV-resistant coating (3-5% UV absorber) after plasma cleaning, improving UV resistance by 50% and extending service life to 8-10 years. Complies with EU REACH standards, non-toxic and environmentally friendly 2.

- Corrosion-Resistant Treatment: For coastal areas (Southeast Asia, South America) and chemical industries, add anti-corrosion additives during raw material mixing and apply a fluorocarbon coating. The treated grille can withstand 2000+ hours of salt spray corrosion (ASTM B117 standard) and resist most chemical solvents 4.

- Anti-Slip Surface Treatment: Two anti-slip treatments for different scenarios: ① Grit coating (aluminum oxide grit + polyurethane adhesive) for industrial platforms; ② Embossed molding (integrated during extrusion) for agricultural and residential use. Both treatments ensure long-term anti-slip performance without peeling6.

- Color Coating & Logo Printing: High-temperature dyeing (color fastness ≥4 grade) supports RAL full-color customization; REACH-compliant ink printing for brand logos, load-bearing parameters, and warning signs. The color and logo remain intact even after long-term outdoor use and friction 6.

🌐 Global Application Scenarios: Covering Multiple Industries

Our plastic grille is widely used in various industries worldwide, providing targeted solutions for different regional needs:

🏗️ Construction & Infrastructure

- Industrial Platforms & Walkways: FRP and HDPE grilles for European chemical plants, North American oil refineries, and Asian power stations — corrosion-resistant, anti-slip, and safe for high-risk environments 67.

- Drainage Channels & Gullies: PP and HDPE grilles for Southeast Asian urban drainage systems, African agricultural irrigation channels, and European residential areas — excellent drainage, anti-clogging, and easy maintenance 15.

- Architectural Decoration: Custom-shaped PVC and FRP grilles for Asian commercial buildings, European shopping malls, and North American landscape projects — lightweight, aesthetic, and customizable in color and shape 58.

🍎 Agriculture & Horticulture

- Greenhouse Floors & Benches: HDPE grilles for European organic greenhouses, North American flower farms, and Asian vegetable plantations — drainage, ventilation, and corrosion-resistant to fertilizer and pesticide 19.

- Livestock Pens & Poultry Coops: PP grilles for African cattle farms, South American poultry farms, and Asian pig farms — anti-slip, easy to clean, and resistant to animal waste corrosion. It improves breeding hygiene and reduces disease risks 56.

- Agricultural Drainage & Irrigation: Large-grid HDPE grilles for African farmland drainage channels and Southeast Asian paddy fields — preventing s