Perforated Mesh: High-Precision, Versatile for Global Industrial Applications

When global industries demand high-precision, durable, and versatile screening, filtering, or conveying solutions—from automotive manufacturing to food processing, construction to electronics—our Perforated Mesh stands out as the ultimate choice. Crafted from premium metals with advanced punching technology, our perforated mesh boasts uniform hole distribution, exceptional structural strength, and customizable specifications to adapt to diverse harsh environments. Unlike traditional woven mesh, it offers precise hole control, stable load-bearing capacity, and superior resistance to wear and impact. Trusted by enterprises across North America, Europe, Asia-Pacific, Africa, and South America, our perforated mesh complies with global industry standards, making it a reliable investment for optimizing your production efficiency and product quality.

🌟 Core Features: Why Global Industries Choose Our Perforated Mesh

Every aspect of our perforated mesh is engineered to address critical pain points in global industrial applications, delivering consistent performance in demanding conditions:

✅ Premium Material Selection & Global Standard Compliance

- Diverse Material Options: We offer perforated mesh in carbon steel, stainless steel (304, 316L, 310S), aluminum, copper, and galvanized steel. 304 stainless steel balances cost and corrosion resistance, ideal for European and Asian food processing; 316L excels in salt spray and chemical resistance, perfect for Southeast Asian coastal projects and North American pharmaceutical industries (complies with FDA & GMP standards); 310S withstands high temperatures up to 1100℃, suitable for Middle Eastern metallurgical plants. Material thickness ranges from 0.3mm to 20mm, accommodating various load requirements 13.

- Comprehensive Global Certifications: All perforated mesh products pass strict quality inspections, meeting EU CE, US UL, ISO 9001, ISO 14001, and ASTM standards. Food-grade models comply with FDA 21 CFR Part 177, while construction-grade products meet EN 10025 standards. Complete SGS/Intertek test reports ensure hassle-free customs clearance in 120+ countries 25.

✅ High-Precision Punching & Customizable Specifications

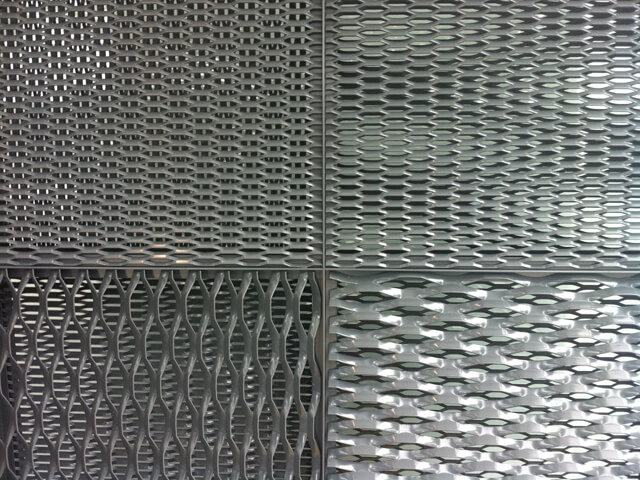

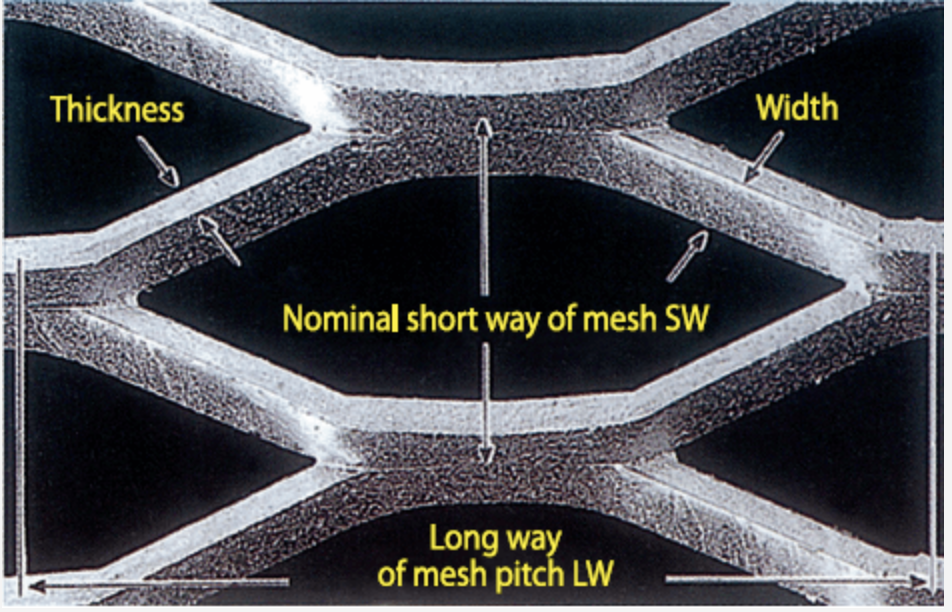

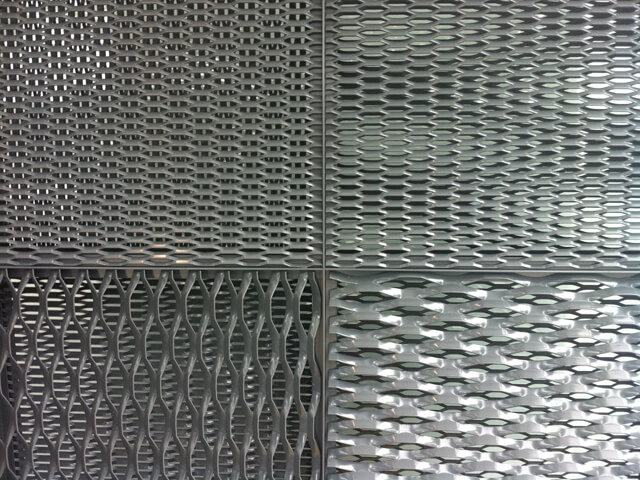

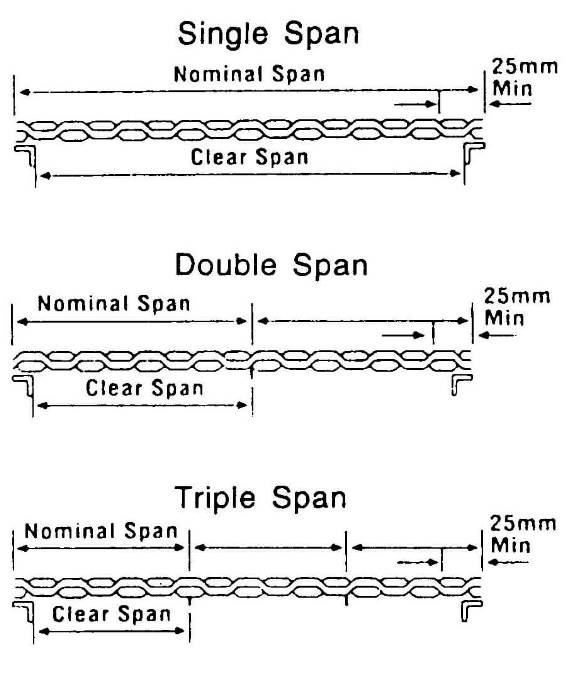

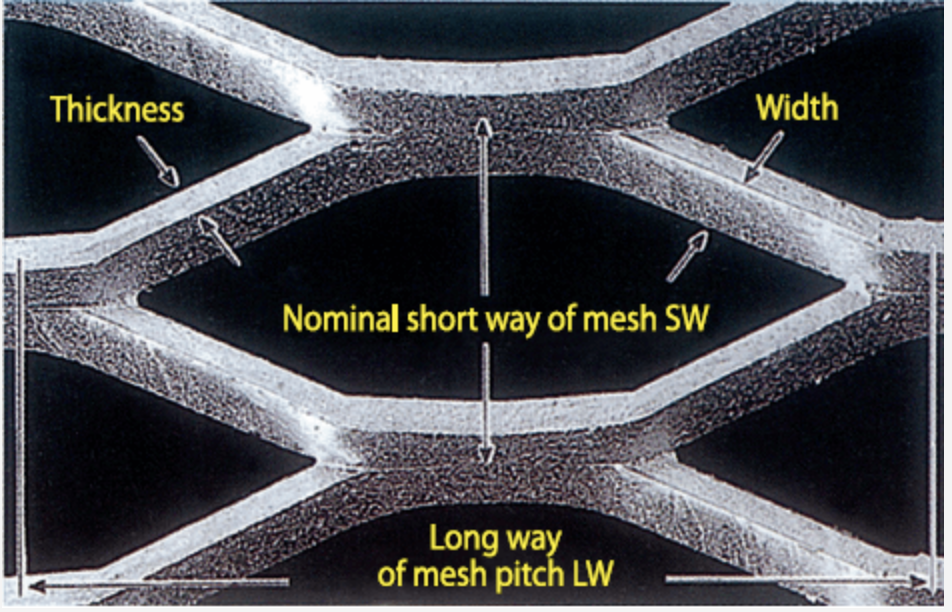

- Precision Hole Design: Adopting CNC turret punching machines and laser punching technology, our perforated mesh achieves hole diameter accuracy of ±0.01mm. Common hole patterns include round, square, rectangular, hexagonal, slotted, and custom shapes. Hole size ranges from 0.5mm to 100mm, with open area ratio adjustable from 10% to 70%, ensuring optimal screening, filtering, and ventilation performance 46.

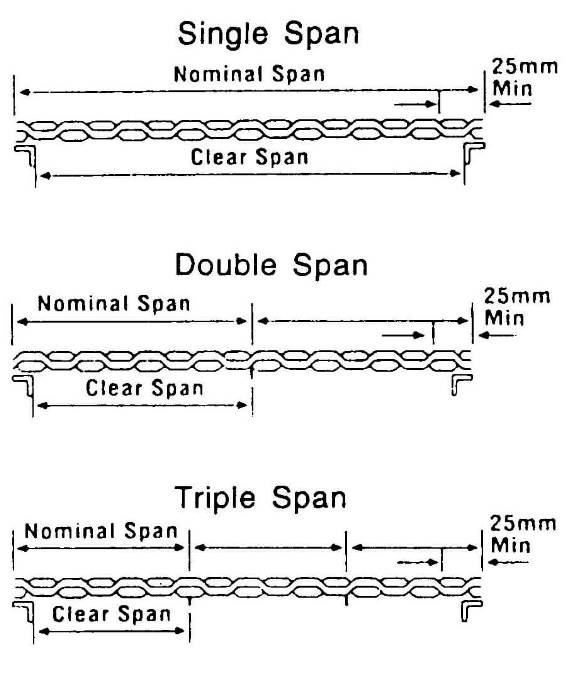

- Fully Customizable Dimensions: Mesh width can be customized from 300mm to 3000mm, length from 1m to 10m (or coil form for continuous use). We also offer tailored edge treatments (folded, welded, polished) and surface modifications to match your specific application scenarios, such as high-temperature resistance, anti-slip, or anti-corrosion 37.

✅ Exceptional Durability & All-Environment Adaptability

- Superior Structural Strength: The one-piece punching process ensures the mesh retains the original mechanical properties of the material, with tensile strength 30% higher than woven mesh. It can withstand heavy loads (up to 500kg/m²) and impact, making it suitable for heavy-duty applications like construction scaffolding and automotive parts conveying 69.

- Extreme Condition Resistance: ① High-Temperature (310S model up to 1100℃): Ideal for Middle Eastern glass and steel factories; ② Corrosive Environments (316L model with 5000+ hours salt spray resistance): Suitable for Southeast Asian chemical plants and coastal infrastructure; ③ Low-Temperature (down to -40℃): Maintains flexibility for Northern European cold storage; ④ Wear Resistance: High-hardness materials (HRC 40-55) resist abrasion from granular materials 58.

- Low Maintenance & Longevity: Smooth surface and corrosion-resistant materials reduce maintenance needs—only regular cleaning is required. Service life ranges from 5-15 years (2-3 times longer than ordinary mesh) under normal operation, with global availability of standardized spare parts 79.

🏭 Advanced Manufacturing Process: The Foundation of Precision

The exceptional quality of our perforated mesh lies in strict control over every manufacturing step, combining advanced technology with rigorous quality management to meet global industrial standards:

- Material Selection & Cutting: High-grade metal coils/sheets are selected based on customer requirements and inspected for surface defects, thickness uniformity, and mechanical properties. The material is then cut into required sizes using CNC shearing machines, ensuring dimensional accuracy ±0.5mm 47.

- Precision Punching: For small to medium holes (0.5-20mm), CNC turret punching machines with high-speed stamping heads (up to 1200 strokes/min) are used; for large or complex holes (20-100mm) or thin materials, laser punching technology is adopted to avoid material deformation. The punching process is computer-controlled to ensure uniform hole distribution and consistent hole size 26.

- Edge Treatment & Forming: The punched mesh undergoes edge trimming to remove burrs and sharp edges, ensuring safe handling. Optional edge treatments include folded edges (for increased rigidity), welded edges (for connection), or flanging. For curved or special-shaped applications, the mesh is formed using hydraulic presses 58.

- Heat Treatment (Optional): For high-temperature or high-strength applications, the perforated mesh undergoes annealing or quenching heat treatment to eliminate internal stress, enhance tensile strength and toughness. 310S stainless steel mesh undergoes solution treatment at 1150-1200℃ to improve high-temperature resistance 9.

- Surface Treatment: According to application needs, surface treatments such as galvanizing, passivation, or painting are performed (detailed in the next section) 3.

- Final Inspection & Packaging: Finished perforated mesh undergoes strict inspections, including hole size accuracy, open area ratio, surface flatness, and mechanical performance tests. Qualified products are packaged with moisture-proof films and wooden pallets to ensure safe transportation, accompanied by complete test reports 9.

✨ Professional Surface Treatment: Enhance Performance & Longevity

Targeted surface treatment further improves the corrosion resistance, wear resistance, and aesthetics of our perforated mesh, enabling it to adapt to diverse global environments. We offer the following surface treatment solutions:

1. Basic Surface Treatment

- Galvanizing Treatment: Hot-dip galvanizing or electro-galvanizing forms a zinc layer (thickness 85-100μm) on the mesh surface, increasing corrosion resistance by 80%. Ideal for outdoor construction, agricultural machinery, and coastal projects in Southeast Asia and Africa 58.

- Passivation Treatment: Using nitric acid or citric acid solution, a dense oxide film is formed on stainless steel mesh surfaces, enhancing corrosion resistance in acidic/alkaline environments. Widely used in North American and European chemical and pharmaceutical industries 39.

- Polishing Treatment: The mesh surface is polished to Ra ≤0.2μm, ensuring a smooth, hygienic surface that avoids material adhesion and scratches. Suitable for food processing, electronic component manufacturing, and decorative applications 46.

- Pickling Treatment: Removes oxide scale and oil stains from the mesh surface, improving surface finish and enhancing the adhesion of subsequent coatings. Used for pre-treatment before painting or coating 7.

2. Optional Functional Coating Treatment

- PTFE Coating: Applied to food and chemical industry mesh, it enhances anti-adhesion and corrosion resistance (resists acids, alkalis, and organic solvents) and can withstand temperatures up to 260℃ 6.

- Ceramic Coating: For high-temperature and abrasive environments (metallurgy, mining), it increases surface hardness to HRC 60-70, extending service life by 2-3 times 7.

- Anti-Static Coating: Tailored for electronic and flammable material applications, it achieves surface resistance of 10⁶-10⁹Ω, complying with ANSI/ESD S20.20 standards to avoid static damage3.

- Powder Coating: Available in various colors, it provides excellent corrosion resistance and aesthetics. Suitable for decorative applications, automotive parts, and outdoor equipment 8.

🌍 Global Application Scenarios: Powering Diverse Industries

Our perforated mesh is widely used in global industrial sectors, providing reliable solutions for screening, filtering, conveying, ventilation, and protection:

1. Industrial Manufacturing

- Automotive Industry: 304 stainless steel perforated mesh for European and North American automotive factories, used in engine air filters, exhaust systems, and interior decorative panels.

- Metallurgy & Mining: 310S high-temperature perforated mesh for Middle Eastern metallurgical plants, used in sintering equipment and ore screening; wear-resistant ceramic-coated mesh for Australian mining sites.

- Electronics Industry: Anti-static polished perforated mesh for Asian electronic factories, used in circuit board production lines and component storage racks.

2. Food & Pharmaceutical

- Food Processing: 316L stainless steel polished perforated mesh for European and Asian food factories, used in grain screening, fruit sorting, and oil filtration (complies with FDA and HACCP standards).

- Pharmaceutical Industry: 316L passivated perforated mesh for North American pharmaceutical plants, used in powder screening and drug conveying (meets GMP requirements).

3. Construction & Infrastructure

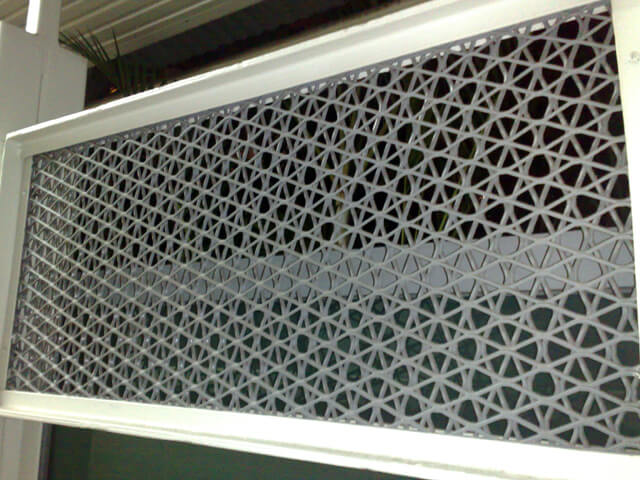

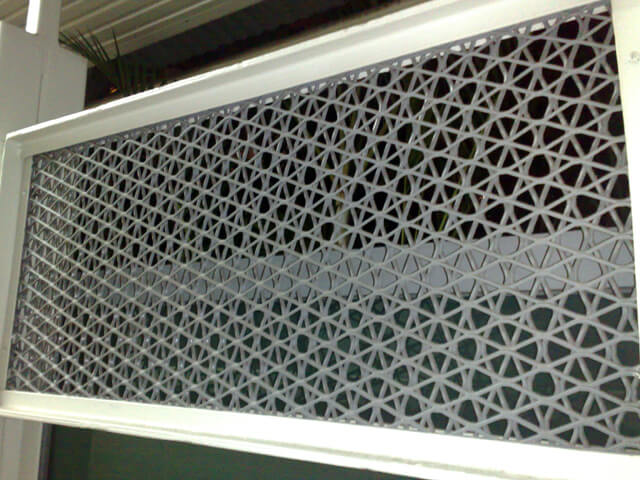

- Building Facades: Aluminum perforated mesh for global high-rise buildings, used for exterior cladding (aesthetic and ventilating).

- Noise Reduction: Slotted perforated mesh for European highway and railway noise barriers.

- Water Treatment: 316L perforated mesh for Southeast Asian and North American wastewater treatment plants, used in filter screens and sedimentation tanks.

4. Agriculture & Environmental Protection

- Agricultural Machinery: Galvanized perforated mesh for African and Asian agricultural equipment, used in seed screens and fertilizer spreaders.

- Air Purification: High-precision perforated mesh for global air purifiers and dust collectors.

🤝 Your Trusted Global Partner for Perforated Mesh

We understand the complexities of global trade and the diverse needs of industrial applications. We provide comprehensive support to ensure seamless cooperation:

- Full Customization & OEM/ODM Services: Tailor material, hole pattern, size, and surface treatment to your regional and application needs. Offer branded packaging, 8+ language manuals, and custom logos.

- Flexible Cooperation Terms: Accept small trial orders (1-10 sheets/coils for standard models); bulk orders enjoy tiered discounts. Short lead times: 10-20 days for standard orders, 20-35 days for custom orders.

- Global Logistics & After-Sales Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide 24/7 multilingual after-sales service, including on-site installation guidance and global spare parts supply.

📞 Get Your Custom Perforated Mesh Solution Today

Whether you’re an automotive manufacturer in Europe, a construction company in Southeast Asia, a food processor in North America, or a mining enterprise in Africa, we have the perfect perforated mesh for your needs. Send your inquiry now for free technical consultation, a customized quote, and detailed product specifications. Let’s build efficient, stable, and durable industrial systems together!