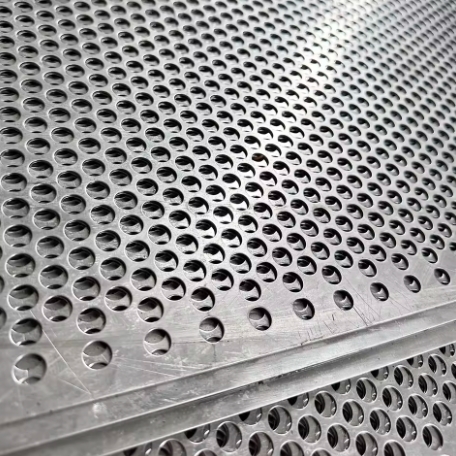

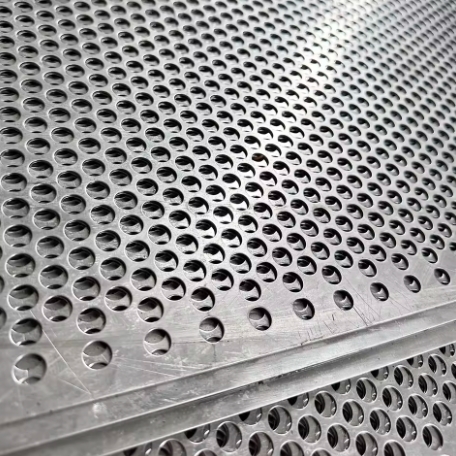

Premium Perforated Metal Mesh: Versatile, Durable & Precision-Made for Global Applications

Perforated metal mesh, a high-performance metal product crafted by precision punching or drilling on premium metal sheets, is globally recognized for its exceptional structural strength, precise hole patterns, excellent ventilation/filtration performance, and aesthetic versatility. Traditional metal meshes often suffer from irregular holes, weak load-bearing capacity, and poor adaptability to extreme environments, limiting their application scope. Our premium perforated metal mesh is engineered with high-quality metal materials, advanced precision punching technology, and global standard compliance, tailored to the diverse needs of 120+ countries across North America, Europe, Asia-Pacific, Africa, and South America. Trusted by construction, automotive, aerospace, food processing, and environmental protection industries worldwide, it’s the reliable choice for applications requiring both functionality and aesthetics.

🌍 What Makes Our Perforated Metal Mesh Globally Preferred?

We don’t just produce perforated metal mesh—we optimize material selection, hole pattern design, and surface treatment to adapt to diverse global working environments, from European high-rise building facades and North American automotive factories to Southeast Asian coastal filtration systems and African mining sites. Every feature is designed to solve hole precision, structural stability, corrosion resistance, and application versatility pain points, ensuring consistent performance in complex scenarios:

✅ High-Quality Metal Materials & Global Standard Compliance

- Multi-Material Options for Diverse Needs: We offer a full range of metal materials to meet global application requirements: ① 304/316L Stainless Steel: Excellent corrosion resistance and rust resistance, suitable for marine, chemical, and food-grade scenarios in Europe and North America, complying with EU FDA and US NSF standards; ② Carbon Steel: High structural strength and cost-effectiveness, ideal for construction reinforcement and industrial screening in South America and Africa; ③ Aluminum Alloy: Lightweight, corrosion-resistant, and good thermal conductivity, suitable for automotive parts and architectural decoration in Asia-Pacific; ④ Copper/Brass: Excellent electrical conductivity and aesthetic appeal, used in electronic components and decorative applications in Europe 13.

- High Purity & Stable Material Performance: All metal sheets adopt high-purity raw materials with low impurity content (sulfur, phosphorus ≤0.03%), ensuring uniform internal structure and stable mechanical properties. The sheets undergo strict quality inspection before processing, complying with EU EN 10025, US ASTM A36, and ISO 9001 standards, laying a solid foundation for precision punching25.

- Non-Toxic & Environmental Protection: The metal materials are non-toxic, tasteless, and free of heavy metals (lead, cadmium ≤0.001%). Our production processes adopt environmentally friendly technologies, complying with EU RoHS and US EPA standards, and all materials are 100% recyclable, meeting global green development requirements 46.

✅ Precision Punching & Diversified Hole Patterns

- Advanced Precision Punching Technology: We adopt CNC precision punching machines and laser punching technology, ensuring high hole precision (diameter error ≤±0.01mm) and uniform hole distribution. The punching process is controlled by an intelligent computer system, avoiding burrs, deformation, and edge curling of the mesh. For thick metal sheets (up to 10mm), we use heavy-duty punching machines to ensure smooth hole formation and no damage to the sheet structure 47.

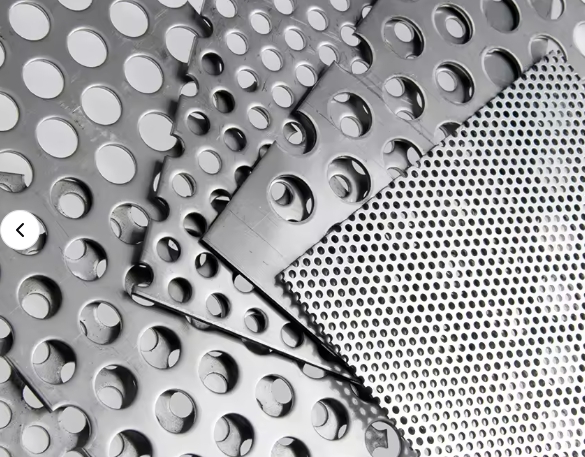

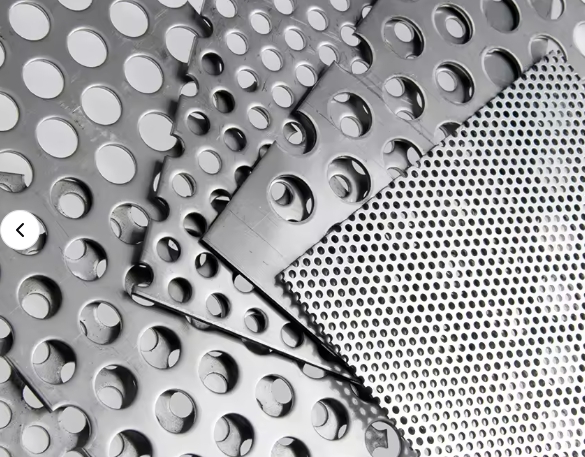

- Diversified Hole Patterns & Customization: We offer a full range of standard hole patterns to meet global market needs: ① Round Holes: The most widely used, suitable for ventilation, filtration, and decoration, with hole diameters from 0.5mm to 50mm; ② Square Holes: Good load-bearing capacity, used in screening and reinforcement, with side lengths from 1mm to 30mm; ③ Slotted Holes: Excellent ventilation and drainage, suitable for outdoor construction and automotive parts; ④ Special Patterns (Hexagonal, Diamond, Decorative): Customized for architectural decoration and special industrial applications. We also support custom hole patterns, hole sizes, and hole spacing according to customer drawings 26.

- Controllable Open Area Ratio: The open area ratio (percentage of hole area to total mesh area) can be customized from 10% to 70% according to application needs. A high open area ratio ensures excellent ventilation and filtration efficiency, while a low open area ratio enhances structural strength, adapting to different functional requirements such as screening, sound insulation, and light transmission 58.

✅ High Structural Strength & All-Environment Adaptability

- Excellent Load-Bearing & Impact Resistance: The perforated metal mesh maintains high structural strength due to the uniform distribution of holes and the integrity of the metal matrix. The tensile strength reaches ≥350MPa (for carbon steel) and ≥500MPa (for 304 stainless steel), and it can withstand impact loads of ≥10J without deformation. It is suitable for heavy-duty applications such as construction platforms and industrial machinery protection 47.

- Corrosion Resistance & Long Service Life: The surface of the mesh undergoes professional surface treatment: stainless steel mesh is passivated to form a dense oxide film; carbon steel mesh is galvanized (hot-dip/electro-galvanized) or powder-coated; aluminum alloy mesh is anodized. These treatments significantly enhance corrosion resistance, making the mesh withstand 2000+ hours of salt spray corrosion (ASTM B117 standard) for stainless steel and 1500+ hours for galvanized carbon steel. The service life reaches 8-15 years for stainless steel and 5-8 years for carbon steel, far exceeding ordinary perforated meshes 58.

- Stable Performance in Extreme Conditions: The mesh maintains stable performance in extreme temperatures (-40℃ to 800℃, depending on material), avoiding brittle fracture in cold regions (Northern Europe, Canada) and softening in high-temperature environments (Middle East, Africa). It also has excellent weather resistance, resisting UV radiation, rain, and wind erosion, suitable for outdoor long-term use 69.

✅ Versatile Specifications & User-Friendly Design

- Comprehensive Specification Coverage: Supports customization of sheet thickness (0.1mm to 10mm), mesh size (100×200mm to 2000×4000mm), and edge treatment (plain edge, folded edge, welded edge). Common standard sizes (1000×2000mm, 1220×2440mm) are available in stock for immediate delivery, adapting to different application scenarios and installation requirements 26.

- User-Friendly Installation & Maintenance: The mesh is designed with pre-drilled installation holes (optional) for easy fixing with bolts, screws, or clips. The smooth surface and regular hole patterns prevent dust and debris accumulation, making it easy to clean with water or a brush. No special maintenance is required, saving users time and effort 89.

- Aesthetic Versatility: The diversified hole patterns and surface finishes (bright, matte, colored) make the perforated metal mesh not only functional but also aesthetically pleasing. It can be used as architectural decoration materials to create unique visual effects, meeting the aesthetic needs of different regions and industries 13.

🏭 Advanced Manufacturing Process & Strict Quality Control

The reliable performance of our perforated metal mesh stems from sophisticated manufacturing processes and rigorous quality control systems, ensuring that every mesh meets global safety and quality standards:

1. Core Manufacturing Processes

- Raw Material Selection & Cutting: Select high-quality metal sheets that comply with global standards, and cut them into the required size (error ≤±1mm) using precision shearing machines or laser cutting machines according to customer orders47.

- Precision Punching/Laser Drilling: For thin sheets (≤3mm), use CNC laser punching machines for high-precision hole forming; for thick sheets (>3mm), use CNC mechanical punching machines. The punching parameters (pressure, speed, position) are strictly controlled by a computer system to ensure hole precision and uniformity. For custom hole patterns, we use CAD software for pattern design and simulation before production26.

- Edge Treatment & Forming: The punched mesh undergoes edge trimming to remove burrs and sharp edges. According to application needs, edge folding, edge welding, or reinforcement frame installation is performed to enhance structural stability. For curved or special-shaped meshes, hydraulic forming machines are used for shaping 58.

- Surface Treatment & Finishing: The formed mesh undergoes surface treatment according to material type: stainless steel mesh is passivated (nitric acid solution); carbon steel mesh is galvanized (hot-dip galvanizing temperature 450-460℃) or powder-coated (electrostatic spraying, curing temperature 180-200℃); aluminum alloy mesh is anodized. After surface treatment, the mesh is cleaned and dried to remove surface impurities 9.

- Final Inspection & Packaging: The finished mesh is inspected for hole precision, hole distribution, surface quality, and dimensional accuracy. It is then packaged in moisture-proof plastic films, wooden pallets, or custom cartons. The packaging can be printed with brand logos, product specifications, and installation instructions in 5+ languages to ensure safe transportation and enhance brand influence9.

2. Strict Quality Control System

- Raw Material Inspection: Each batch of metal sheets is tested for chemical composition (spectrometer), mechanical properties (tensile strength tester), and surface quality (no scratches, pits) to ensure compliance with global standards. Test reports are provided for customer review 37.

- In-Process Quality Supervision: During punching, real-time inspections are conducted on hole diameter, hole spacing, and hole distribution using a coordinate measuring machine and a magnifying glass. During surface treatment, the thickness of the galvanized layer/powder coating and the quality of the passivation film are inspected to ensure uniformity and adhesion 68.

- Final Performance Testing: Finished products undergo comprehensive testing, including load-bearing capacity, impact resistance, corrosion resistance (salt spray test, ASTM B117), and high-temperature resistance. A 2% random sampling method is adopted for each batch, and only products that pass all tests are allowed to leave the factory. Complete SGS/Intertek test reports are provided for bulk orders 9.

🌍 Global Application Scenarios: Covering Diverse Industries

Our perforated metal mesh is widely used in global construction, industrial manufacturing, automotive, aerospace, environmental protection, and other fields, providing reliable solutions for various functional and decorative needs:

🏗️ Construction & Architectural Decoration

- Building Facades & Cladding: Aluminum alloy and stainless steel perforated mesh with decorative hole patterns for European and North American high-rise buildings. The mesh provides sunshade, ventilation, and sound insulation effects while creating unique architectural aesthetics 13.

- Interior Decoration & Partitioning: Thin stainless steel and copper perforated mesh for Asian and European commercial spaces (shopping malls, hotels, offices). Used as partitions, ceiling decorations, and wall panels, adding a sense of fashion and layering 25.

- Outdoor Facilities: Galvanized carbon steel perforated mesh for African and South American outdoor fences, railings, and platforms. The corrosion resistance and load-bearing capacity adapt to outdoor harsh environments 46.

🏭 Industrial Manufacturing & Screening

- Industrial Screening & Classification: Carbon steel and stainless steel perforated mesh with different hole sizes for global mining, chemical, and food processing industries. Used for screening ores, grains, and chemical raw materials, ensuring precise classification 79.

- Machinery Protection & Ventilation: Thick stainless steel perforated mesh for North American and European industrial machinery (motors, generators, pumps). Used as protective covers and ventilation grilles, preventing debris from entering and ensuring heat dissipation 48.

- Filtration Systems: Fine-hole stainless steel perforated mesh for Southeast Asian and Middle Eastern chemical and water treatment plants. Used as filter elements in liquid and gas filtration systems, ensuring high filtration efficiency 69.

🚗 Automotive & Aerospace

- Automotive Parts: Aluminum alloy and stainless steel perforated mesh for global automotive manufacturers. Used as radiator grilles, exhaust filters, and sound insulation panels, improving automotive performance and safety 26.

- Aerospace Components: High-precision stainless steel perforated mesh for European and North American aerospace industries. Used in aircraft engine components and cabin ventilation systems, meeting strict aerospace quality standards 47.

🌍 Environmental Protection & Energy

- Wastewater Treatment: Stainless steel perforated mesh for global wastewater treatment plants. Used as filter screens and aeration discs, improving wastewater treatment efficiency 69.

- Solar Energy & Wind Power: Aluminum alloy perforated mesh for Asian and North American solar panels and wind turbine components. Used as protective covers and heat dissipation materials, ensuring the stable operation of renewable energy equipment 35.

🍎 Food & Medical

- Food Processing: Food-grade 304/316L stainless steel perforated mesh for European and North American food processing plants. Used as sieves, conveyor belts, and drying trays, complying with FDA/NSF standards and ensuring food safety 79.

- Medical Equipment: High-precision stainless steel perforated mesh for European medical equipment manufacturers. Used in medical filters and diagnostic equipment components, meeting medical grade requirements (ISO 13485) 48.

🌍 Your Trusted Global Perforated Metal Mesh Partner

We understand the complexities of global trade and the high requirements of perforated metal mesh in diverse industries. We provide comprehensive support to ensure smooth cooperation:

- Global Standard Compliance: Passes ISO 9001, EU EN 10025, US ASTM A36, and FDA/NSF standards. Provides complete SGS/Intertek test reports (chemical composition, corrosion resistance, hole precision) for hassle-free customs clearance in 120+ countries 39.

- Full Customization Service: Tailor material, hole pattern, hole size, mesh size, surface treatment, and packaging to regional needs. Support OEM/ODM with branded packaging, multilingual product manuals, and custom logos to help you build local brand loyalty.

- Flexible Cooperation Terms: Accept small trial orders (50pcs for standard sizes) for new partners; bulk orders enjoy tiered pricing discounts. Short production lead time: 7-15 days for standard orders, 15-25 days for custom orders.

- Efficient Logistics & Multilingual Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide 24/7 after-sales service in 5+ languages to solve your problems anytime, including technical consultation, order tracking, and quality feedback.

📞 Get Your Custom Perforated Metal Mesh Solution Today

Whether you’re an architectural firm in Europe, an automotive manufacturer in North America, a mining company in Africa, or a food processing plant in Asia-Pacific, we have the perfect perforated metal mesh to meet your local needs. Send your inquiry now to get free samples, a customized quote, and detailed product specifications. Let’s work together to create functional, durable, and aesthetically pleasing solutions!