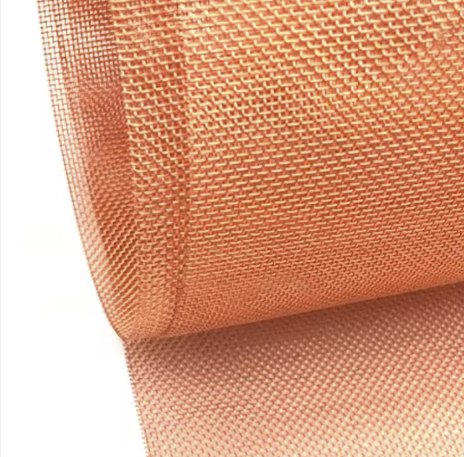

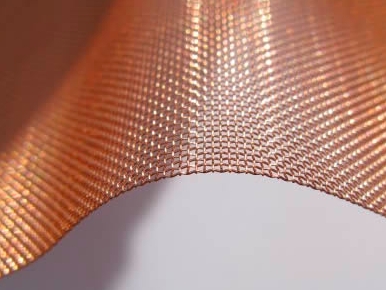

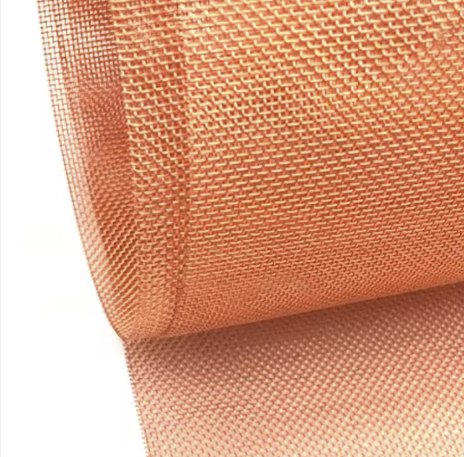

Copper Wire Mesh: High-Conductivity, Corrosion-Resistant for Global Industrial & Decorative Applications

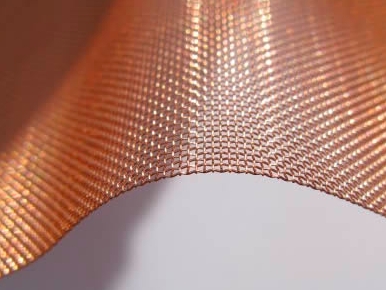

When global industries and designers seek a versatile material that combines high conductivity, excellent corrosion resistance, and unique aesthetic appeal—from electronic manufacturing in Asia to architectural decoration in Europe, and industrial filtration in North America—our Copper Wire Mesh stands out as the premier choice. Crafted from high-purity copper (Cu ≥99.9%) and brass (copper-zinc alloy) via precision weaving technology, our copper wire mesh delivers exceptional performance in conductive shielding, filtration, heat transfer, and decorative scenarios. Unlike ordinary metal meshes, it boasts natural anti-microbial properties, stable chemical performance, and a timeless metallic luster. Compliant with global standards such as ISO 9001, ASTM B134, and EN 1652, our copper wire mesh is trusted by customers across 120+ countries, making it an ideal investment for industrial efficiency enhancement and creative design realization.

🌟 Core Features: Why Global Customers Choose Our Copper Wire Mesh

Every detail of our copper wire mesh is engineered to address diverse global industrial and decorative needs, delivering reliable performance in harsh and sophisticated environments:

✅ Premium Material & Global Standard Compliance

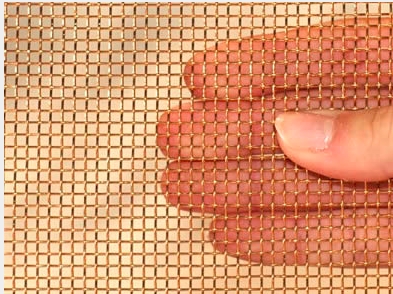

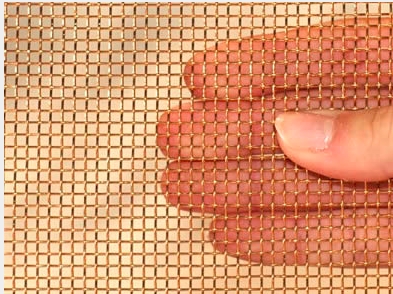

- High-Purity Material Options: We offer copper wire mesh in pure copper (C1100, C1020) and brass (C2600, C2720). Pure copper excels in conductivity (≥98% IACS) and corrosion resistance, ideal for electronic shielding and industrial filtration; brass enhances strength and wear resistance while retaining copper’s advantages, suitable for decorative and marine applications. Wire diameter ranges from 0.02mm to 2.0mm, mesh count from 10 to 600 meshes, fully customizable to meet specific project requirements 13.

- Comprehensive Global Certifications: All copper wire mesh products pass strict quality inspections, meeting EU CE, US ASTM B134, ISO 9001, and RoHS standards. Material purity test reports (SGS/Intertek certified) and corrosion resistance test reports ensure compliance with local regulations in Europe, North America, Asia, and Oceania 25.

✅ Exceptional Functional Performance

- Superior Electrical & Thermal Conductivity: Pure copper wire mesh has electrical conductivity up to 98% IACS and thermal conductivity of 401 W/(m·K), making it perfect for electromagnetic shielding (EMI/RFI), heat dissipation components, and conductive grounding in global electronic and aerospace industries 46.

- Excellent Corrosion & Oxidation Resistance: Copper forms a dense patina layer when exposed to air, effectively preventing further corrosion. It resists most organic acids, alkalis, and salt spray, suitable for marine environments in Southeast Asia, chemical filtration in Europe, and coastal architectural applications 37.

- Natural Anti-Microbial & Hygienic Properties: Copper ions inhibit the growth of bacteria (E. coli, Staphylococcus aureus), viruses, and fungi, with a 99.9% microbial reduction rate within 24 hours. Ideal for food processing, medical equipment, and public hygiene facilities in North America and Europe 58.

✅ Versatile Design & Customization

- Diverse Weave Types: Available in plain weave, twill weave, Dutch weave, and crimped weave. Plain weave for general filtration and decoration; twill weave for high-strength industrial applications; Dutch weave for high-precision filtration (mesh count up to 600 meshes); crimped weave for vibration-resistant scenarios 69.

- Fully Customizable Specifications: Customizable wire diameter, mesh count, sheet size (max width 3000mm, max length 10000mm), and roll size. Optional surface treatments (polishing, patina, coating) to match different aesthetic and functional needs 38.

✅ Durable & Easy to Process

- High Tensile Strength & Longevity: Tensile strength ≥200MPa, with service life ranging from 15-25 years in indoor environments and 10-15 years in outdoor/marine environments—2-3 times longer than ordinary steel mesh in corrosive scenarios 59.

- Flexible & Easy to Install: Lightweight and malleable, copper wire mesh can be easily cut, bent, and shaped to fit complex structures. Suitable for on-site installation in architectural decoration, equipment shielding, and filtration systems 78.

🏭 Advanced Manufacturing Process: The Foundation of Quality

The exceptional performance of our copper wire mesh comes from strict control over every manufacturing step, combining precision technology with rigorous quality management to meet global customer needs:

- Material Selection & Purification: High-purity copper ingots (Cu ≥99.9%) or brass ingots are selected and inspected for chemical composition and impurities. Impurities are removed via vacuum smelting to ensure material purity and conductivity 47.

- Wire Drawing: Purified copper/brass ingots are drawn into fine wires of precise diameters using multi-pass precision drawing machines. The drawing process is controlled by computer to ensure wire diameter error ≤±0.005mm. Annealing treatment (350-450℃) is performed to eliminate internal stress and enhance wire flexibility 26.

- Precision Weaving: Copper/brass wires are woven into mesh using high-speed computer-controlled looms. Different weave types (plain, twill, Dutch) are produced according to customer requirements, with mesh count accuracy ±1 mesh. The weaving process ensures uniform mesh distribution and tight wire bonding 38.

- Trimming & Shaping: The woven copper wire mesh is trimmed into required sheet or roll sizes using CNC cutting machines. Dimensional accuracy is controlled within ±1mm. For custom-shaped products, the mesh is bent and formed using hydraulic presses 59.

- Surface Treatment: According to application needs, surface treatments such as polishing, patina, or coating are performed (detailed in the next section) 3.

- Final Inspection & Packaging: Finished copper wire mesh undergoes strict inspections, including wire diameter measurement, mesh count verification, conductivity testing, and corrosion resistance testing. Qualified products are packaged with moisture-proof films and wooden pallets to prevent oxidation and damage during transportation, accompanied by complete test reports 9.

✨ Professional Surface Treatment: Enhance Performance & Aesthetics

Targeted surface treatment further improves the corrosion resistance, aesthetics, and functional performance of copper wire mesh, enabling it to adapt to diverse global environments and application scenarios. We offer the following surface treatment solutions:

1. Basic Surface Treatment

- Polishing Treatment: The mesh surface is polished to a mirror finish (Ra ≤0.1μm), enhancing metallic luster and aesthetic appeal. Suitable for architectural decoration, furniture, and high-end electronic equipment in Europe and North America 59.

- Natural Patina Treatment: Accelerated natural oxidation forms a uniform, stable patina layer (green or brown) on the surface, enhancing corrosion resistance and vintage aesthetic. Ideal for outdoor architecture, historical building restoration, and decorative art in Europe and South America 78.

- Cleaning & Degreasing: Removes oil stains and impurities from the mesh surface via ultrasonic cleaning, ensuring good conductivity and adhesion of subsequent coatings. Used as pre-treatment for electronic shielding and coating applications 6.

2. Optional Functional Coating Treatment

- Nickel Plating: Forms a thin nickel layer on the mesh surface, enhancing corrosion resistance and wear resistance while retaining conductivity. Suitable for marine environments in Southeast Asia and high-precision electronic components 58.

- Tin Plating: Improves solderability and oxidation resistance, making it ideal for electronic circuit boards, connectors, and soldering applications in Asian and North American electronic industries 7.

- Clear Coating: A transparent protective coating (acrylic or polyurethane) preserves the natural luster of copper and prevents patina formation. Suitable for indoor decoration, furniture, and high-end medical equipment 9.

🌍 Global Application Scenarios: Powering Industrial & Creative Industries

Our copper wire mesh is widely used in global industrial, electronic, architectural, and medical sectors, providing reliable solutions for shielding, filtration, heat transfer, and decoration:

1. Electronic & Electrical Industry

- EMI/RFI Shielding: Pure copper wire mesh for Asian and North American electronic factories, used in mobile phone components, computer cases, and communication equipment to block electromagnetic interference.

- Conductive Components: High-conductivity copper mesh for European aerospace and automotive industries, used in battery packs, heat sinks, and conductive grounding systems.

2. Industrial Filtration & Separation

- Chemical Filtration: Corrosion-resistant copper mesh for European and Southeast Asian chemical plants, used in acid-base solution filtration and catalyst separation.

- Oil & Gas Filtration: Brass wire mesh for Middle Eastern and North American oil fields, used in oil well screens and fuel filtration systems.

- Food & Beverage Filtration: Anti-microbial copper mesh for European and North American food factories, used in wine filtration, sugar refining, and beverage clarification (complies with FDA standards).

3. Architectural Decoration & Construction

- Building Facades: Patinated copper wire mesh for European high-rise buildings and historical restorations, providing unique aesthetic appeal and weather resistance.

- Interior Decoration: Polished copper mesh for global hotels, shopping malls, and luxury homes, used in ceiling panels, wall cladding, and room dividers.

- Insect Screens & Ventilation: Brass wire mesh for Southeast Asian and African residential buildings, used in window screens (corrosion-resistant and insect-proof).

4. Medical & Public Hygiene

- Medical Equipment: Anti-microbial copper mesh for North American and European hospitals, used in medical device components and sterile room ventilation systems.

- Public Facilities: Copper mesh for global public transport hubs and public toilets, used in handrails and ventilation grilles to inhibit microbial growth.

🤝 Your Trusted Global Partner for Copper Wire Mesh

We understand the diverse needs of global customers for copper wire mesh in industrial and decorative applications. We provide comprehensive support to ensure seamless cooperation:

- Full Customization & OEM/ODM Services: Tailor material, wire diameter, mesh count, size, weave type, and surface treatment to your regional market needs. Offer branded packaging, 8+ language technical manuals, and custom logos.

- Flexible Cooperation Terms: Accept small trial orders (10-50 sheets/rolls for standard models); bulk orders enjoy tiered discounts. Short lead times: 7-15 days for standard orders, 15-30 days for custom orders.

- Global Logistics & After-Sales Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide 24/7 multilingual after-sales service, including technical consultation, installation guidance, and global spare parts supply (5-10 years warranty for different surface treatments).

📞 Get Your Custom Copper Wire Mesh Solution Today

Whether you’re an electronic manufacturer in Asia, an architectural designer in Europe, a chemical enterprise in North America, or a decoration supplier in South America, we have the perfect copper wire mesh for your needs. Send your inquiry now for free technical consultation, a customized quote, and detailed product specifications. Let’s power your industrial efficiency and creative designs together!