🌟 Product Introduction: The Backbone of Global Industrial Conveyance

Conveyor Belt Mesh (also called conveyor mesh belt or industrial transmission mesh) is a high-strength, heat-resistant industrial component engineered for continuous material handling. Compliant with international standards (ASTM A480, ISO 9001, EN 10204), it has become an indispensable part of manufacturing, food processing, mining, and logistics sectors in North America, Europe, Asia-Pacific, Africa, and the Middle East.

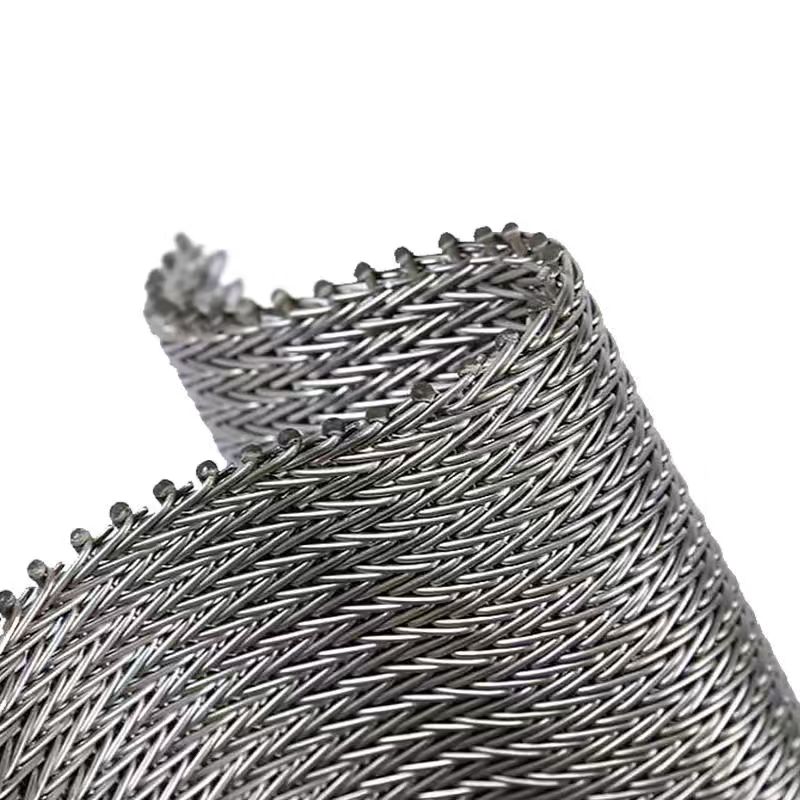

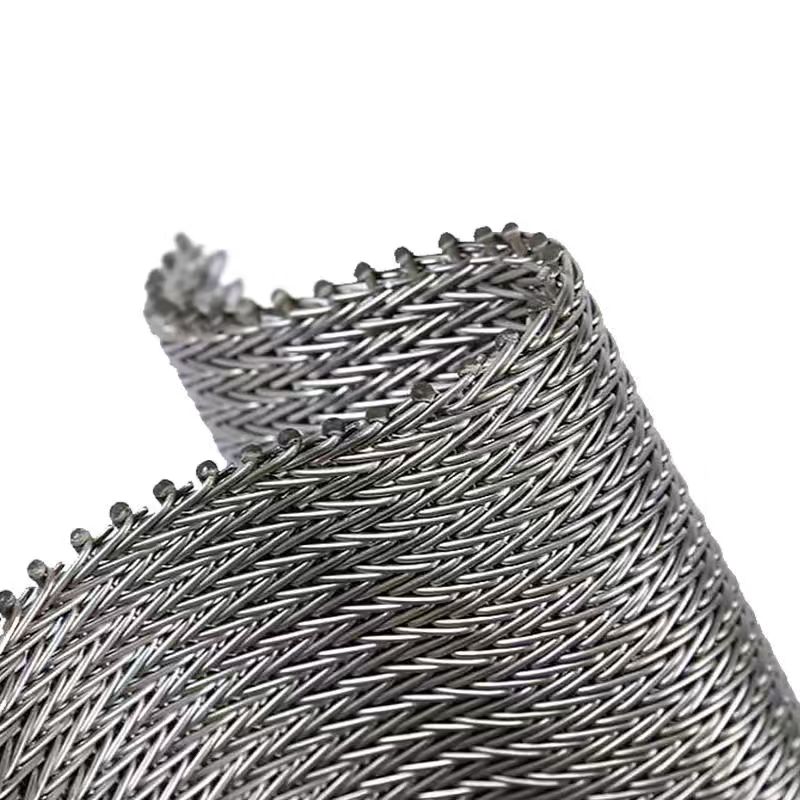

Crafted from premium stainless steel (304/316), carbon steel, or heat-resistant alloy wire, this mesh belt balances exceptional tensile strength, temperature resistance, and corrosion resistance. Its open-mesh structure enables uniform heat transfer, drainage, and visibility—solving critical pain points for global industries requiring efficient, reliable material transmission. Whether for high-temperature baking, heavy-duty mining, or sterile food processing, it’s the trusted choice for engineers and plant managers worldwide.

🛠️ Core Features (Global Competitive Advantages)

1. Superior Strength & Durability for Continuous Operation

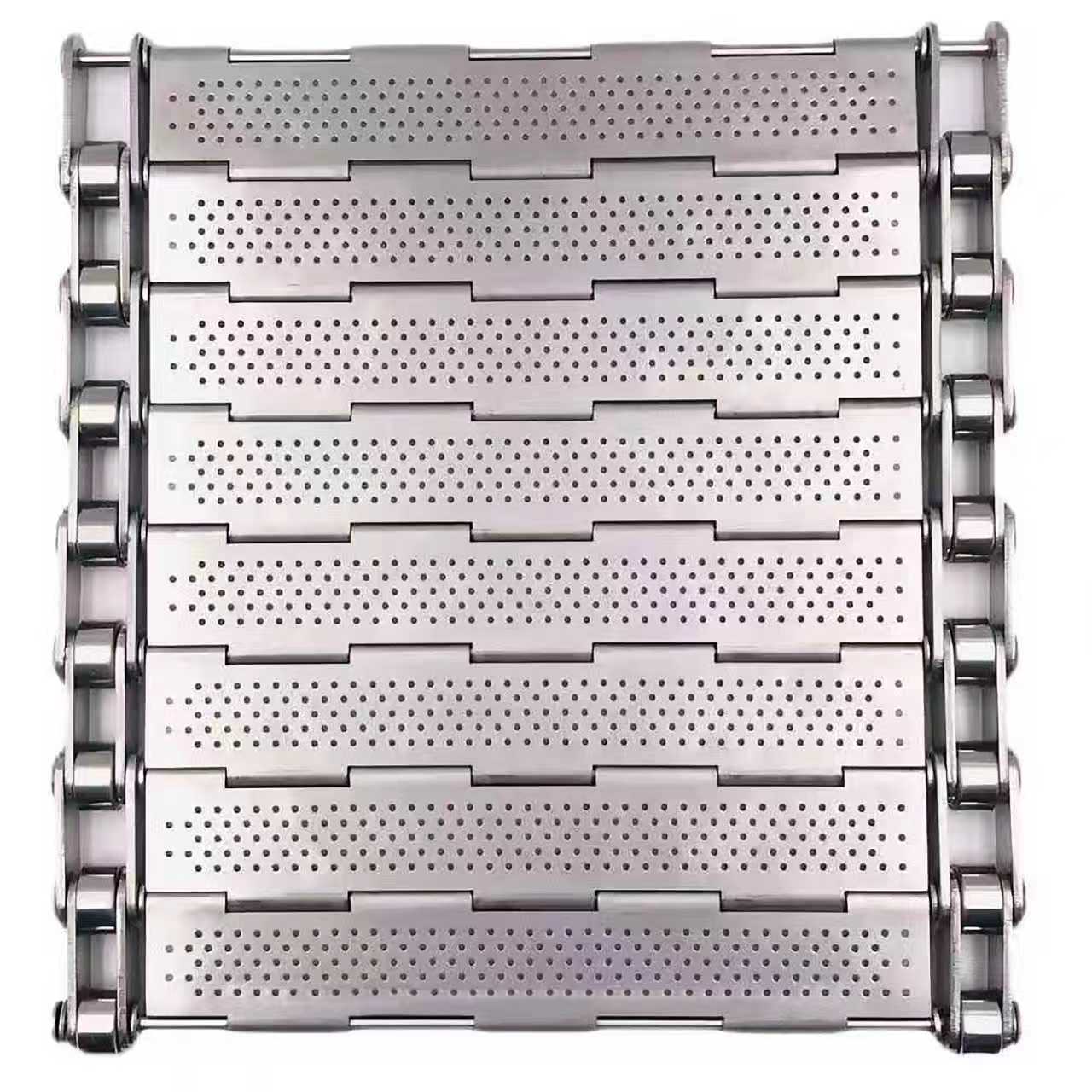

- High-Tensile Construction: Wire diameters range from 1.0mm to 5.0mm, with tensile strength ≥600MPa for carbon steel and ≥700MPa for stainless steel variants. Reinforced edge bars and cross rods enhance load-bearing capacity (up to 500kg/㎡), supporting 24/7 continuous operation.

- Robust Weaving/Welding Technology:

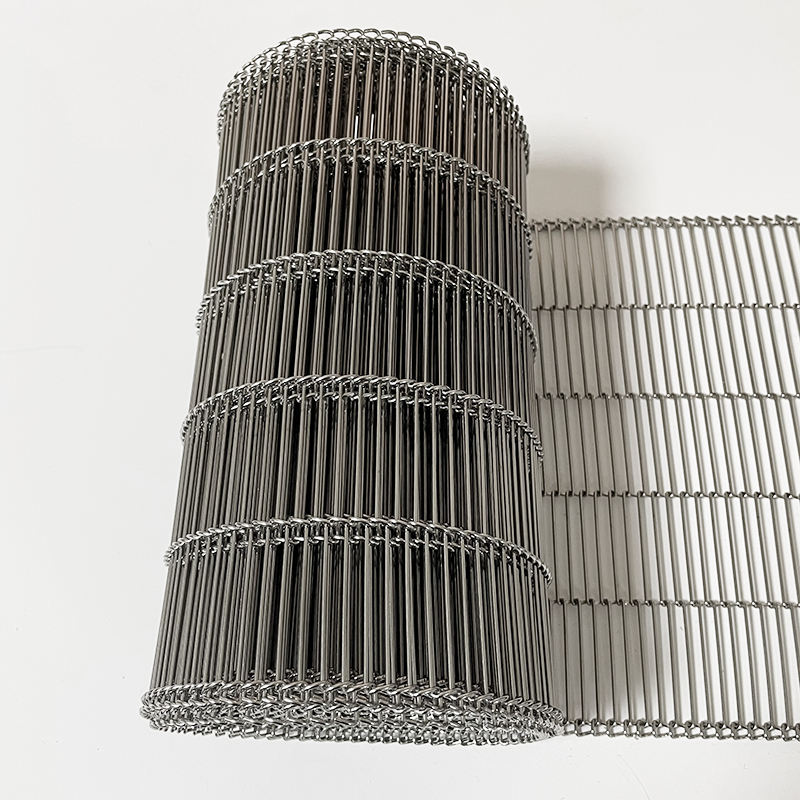

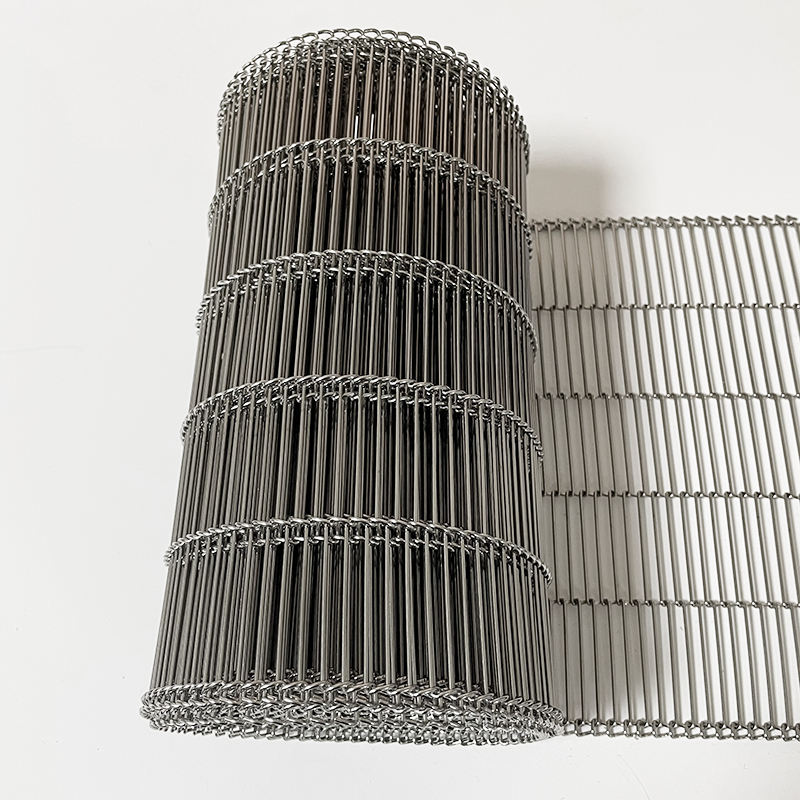

- Woven mesh belt: Interlaced wire design (chain link, plain weave) for flexibility, ideal for curved conveyors and light-to-medium loads.

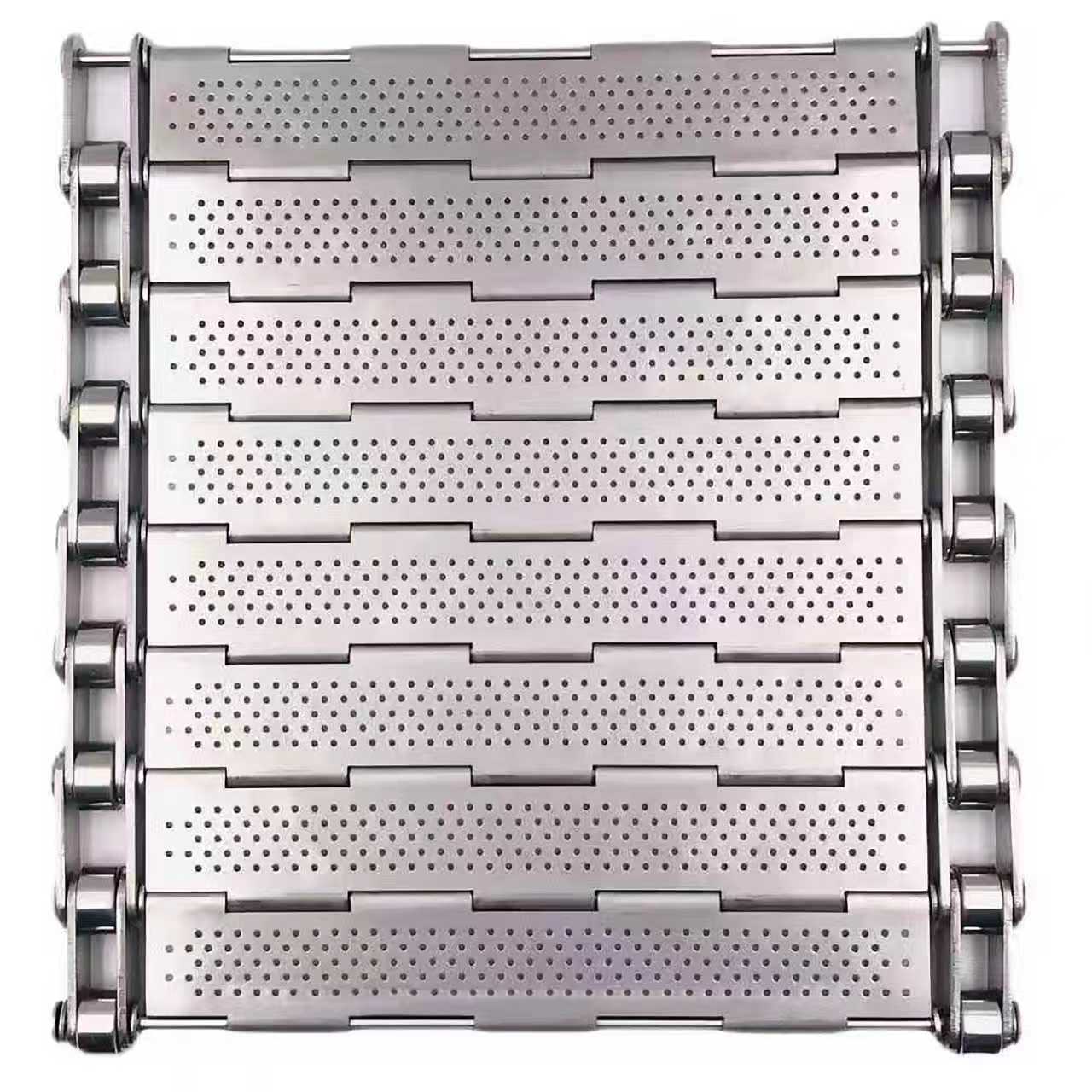

- Welded mesh belt: Precision spot-welded at every cross point (weld shear strength ≥3000N) for rigidity, perfect for heavy-duty mining and high-temperature industrial processes.

- Long Service Life: 5-15 years depending on material and application, outperforming rubber or plastic belts in harsh industrial environments.

2. Extreme Temperature & Corrosion Resistance

- Wide Temperature Adaptability: Withstands -40℃ to 1200℃ (alloy steel variants), resisting thermal shock and deformation—suitable for freezing warehouses (North America/Europe) and high-temperature furnaces (steel mills, ceramic factories).

- Global Climate/Environment Adaptation:

- 304/316 Stainless Steel: Ultimate corrosion resistance to saltwater, acids, and alkalis—ideal for coastal food processing plants (Mediterranean, Southeast Asia) and chemical factories.

- Hot-dip Galvanized Carbon Steel: Cost-effective corrosion protection (salt spray resistance ≥800 hours) for humid mining areas (Africa, South America).

- Heat-Resistant Alloy (Inconel): Withstands 800-1200℃ for industrial baking, smelting, and heat treatment processes (Europe, North America manufacturing hubs).

3. Efficiency & Versatility for Diverse Industries

- Open-Mesh Advantage: 30%-70% open area enables rapid drainage (food washing lines), uniform heat distribution (oven conveyors), and easy cleaning—reducing downtime for maintenance.

- Customizable Specifications: Mesh sizes from 5×5mm to 50×50mm, belt widths from 300mm to 3000mm, and lengths up to 100m. Supports custom edge treatments (chain attachments, guide rails) for seamless integration with existing equipment.

- Low Friction & Energy Saving: Smooth surface reduces friction between belt and rollers, cutting energy consumption by 15%-20% compared to traditional belts.

4. Compliance & Hygiene for Specialized Sectors

- Food-Grade Certification: 304/316 stainless steel mesh belts meet FDA, EU 10/2011, and HACCP standards—non-toxic, easy to sanitize, and suitable for food processing (baking, freezing, washing).

- Eco-Friendly & Recyclable: Made from 100% recyclable metal, aligning with EU REACH, RoHS, and LEED green manufacturing standards.

🌍 Global Applications (Scene-Specific Solutions)

In North America (USA/Canada), stainless steel conveyor belt mesh dominates the food processing industry (bakeries, meat packing plants) and automotive manufacturing (part assembly lines). Heat-resistant alloy belts are used in steel mills and ceramic factories, withstanding extreme temperatures in industrial furnaces.

For Europe (EU/UK), food-grade 316 stainless steel mesh belts are essential for pharmaceutical and dairy processing, complying with strict hygiene regulations. Welded carbon steel mesh belts are favored for mining (coal/ore transportation) and logistics hubs, supporting heavy-duty material handling.

In Southeast Asia (Indonesia/Vietnam), hot-dip galvanized mesh belts are widely used in agricultural processing (palm oil, rice drying) and seafood processing plants, resisting tropical humidity and saltwater corrosion. Lightweight woven mesh belts are used in electronics manufacturing for component conveyance.

For Africa (Nigeria/South Africa), cost-effective carbon steel mesh belts power mining operations (gold, diamond ore transportation) and construction material factories (cement, aggregate conveyance). Their durability and low maintenance suit remote industrial sites with limited service access.

In the Middle East (UAE/Saudi Arabia), 304 stainless steel and heat-resistant alloy mesh belts are critical for oil & gas refineries (chemical processing) and desert-based manufacturing plants. They withstand extreme heat (up to 50℃ ambient) and sandstorms, ensuring uninterrupted operation.

✅ Why Choose Our Conveyor Belt Mesh for Global Export?

- Global Compliance & Certification: Meet ASTM A480, ISO 9001, CE, FDA, and SGS standards—test reports for tensile strength, temperature resistance, and corrosion resistance provided for customs clearance.

- OEM/ODM Expertise: Customize mesh type, wire diameter, belt width/length, edge treatment, and packaging. Support branded labeling for distributors to build local market trust.

- Flexible MOQ & Competitive Pricing: Accept small trial orders (10m/roll) for new partners; bulk pricing discounts for orders over 1000m to maximize your profit margin.

- Comprehensive Global Support: Multilingual technical documents (English, Spanish, Arabic, French) and installation guides; 24/7 after-sales service to resolve issues across time zones.

- Efficient Logistics: Reinforced waterproof packaging (steel core + plastic wrap) reduces sea freight damage; strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets).

Whether you’re supplying food processing plants, mining companies, automotive factories, or logistics hubs, our conveyor belt mesh delivers unbeatable performance, durability, and value. Join 400+ global industrial partners and leverage the world’s most trusted conveyor mesh solution to expand your export business—reliable, adaptable, and built for every industrial challenge!