Premium Stainless Steel Wire: Global Solution for Corrosion-Resistant & High-Strength Applications

Stainless steel wire, a high-performance metal wire product made from premium stainless steel alloys, is globally renowned for its exceptional corrosion resistance, high tensile strength, hygiene, and durability. Traditional carbon steel wire is prone to rust and degradation in humid, acidic, or high-temperature environments, leading to product failure and safety risks. Our premium stainless steel wire is engineered withhigh-purity stainless steel materials, precision processing technology, and global standard compliance, tailored to the industry needs of 120+ countries across North America, Europe, Asia-Pacific, Africa, and South America. Trusted by medical, food, chemical, construction, and electronic industries worldwide, it’s the reliable choice for demanding applications requiring long-term stability and safety.

🌍 What Makes Our Stainless Steel Wire Globally Preferred?

We don’t just produce stainless steel wire—we optimize material selection, processing technology, and surface treatment to adapt to diverse global working environments, from European medical cleanrooms to Southeast Asian coastal chemical plants, and from North American food processing facilities to African high-temperature industrial sites. Every feature is designed to solve corrosion, strength, and hygiene pain points, ensuring consistent performance in extreme and demanding scenarios:

✅ Superior Corrosion Resistance & All-Environment Adaptability

- High-Quality Stainless Steel Alloys: We offer a full range of stainless steel grades to meet global application needs: ① 304 Stainless Steel (1.4301): Excellent general corrosion resistance, resisting acid, alkali, salt, and atmospheric corrosion, suitable for most industrial, food, and construction scenarios; ② 316/316L Stainless Steel (1.4401/1.4404): Enhanced corrosion resistance (especially to chloride ions), ideal for marine, coastal, and chemical environments in Southeast Asia and North America; ③ 310S Stainless Steel (1.4845): High-temperature resistance up to 1200℃, suitable for European industrial furnaces and Middle Eastern high-temperature processing; ④ 430 Stainless Steel (1.4016): Cost-effective, with good oxidation resistance, suitable for dry indoor environments in South America and Africa 13.

- Uniform Material Structure & Purity: Adopts high-purity stainless steel billets with low sulfur and phosphorus content (≤0.03%), ensuring a uniform austenitic/ferritic structure. The wire undergoes vacuum melting and refining to remove impurities, further enhancing corrosion resistance and mechanical properties. All materials comply with EU EN 10088, US ASTM A498, and ISO 6892 standards 25.

- Passivation Treatment for Enhanced Protection: All stainless steel wires undergo professional passivation treatment (using nitric acid or citric acid solution), forming a dense oxide film on the surface. This film significantly improves corrosion resistance, making the wire withstand 2000+ hours of salt spray corrosion (ASTM B117 standard) for 304 grade and 3000+ hours for 316 grade 46.

✅ High Tensile Strength & Mechanical Stability

- Precision Drawing & Heat Treatment: The stainless steel billets undergo 6-10 passes of precision diamond die drawing, achieving precise diameter (error ≤±0.01mm) and smooth surface. According to application needs, we provide different strength grades: soft (annealed), half-hard, and full-hard. The soft wire has excellent ductility for easy shaping; the full-hard wire has high tensile strength (≥1200MPa for 304 grade) for heavy-duty reinforcement scenarios47.

- Stable Performance in Extreme Conditions: The stainless steel wire maintains stable mechanical properties in extreme temperatures (-270℃ to 1200℃, depending on grade), avoiding brittle fracture in cold regions (Northern Europe, Canada) and softening in high-temperature environments (Middle East, Africa). It also has excellent fatigue resistance, withstanding repeated bending and tension without deformation 69.

- Consistent Quality Batch-to-Batch: Advanced production lines and strict quality control ensure uniform diameter, strength, and surface quality across batches. This consistency is critical for mass production industries such as electronics, automotive, and food processing 38.

✅ Hygienic & Environmentally Friendly & Versatile Specifications

- Hygienic & Easy to Clean: The smooth surface of stainless steel wire has no pores or cracks, preventing the growth of bacteria and microorganisms. It is non-toxic, tasteless, and complies with EU FDA and US NSF food safety standards, making it ideal for food processing, medical equipment, and pharmaceutical applications 79.

- Environmentally Friendly & Recyclable: Stainless steel is 100% recyclable, with no environmental pollution during production and use. Our production processes adopt environmentally friendly technologies, complying with EU RoHS and US EPA standards, meeting global green development requirements 35.

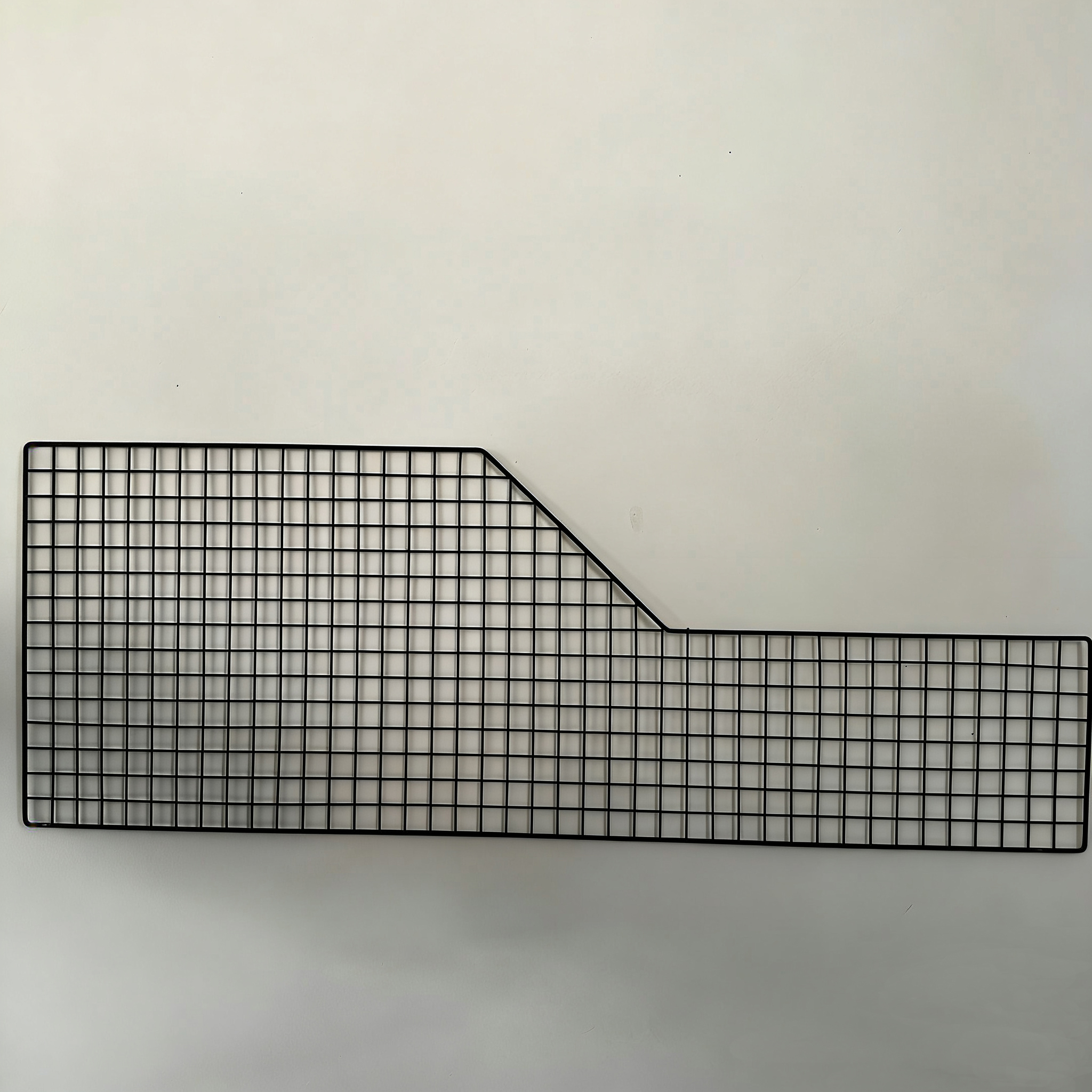

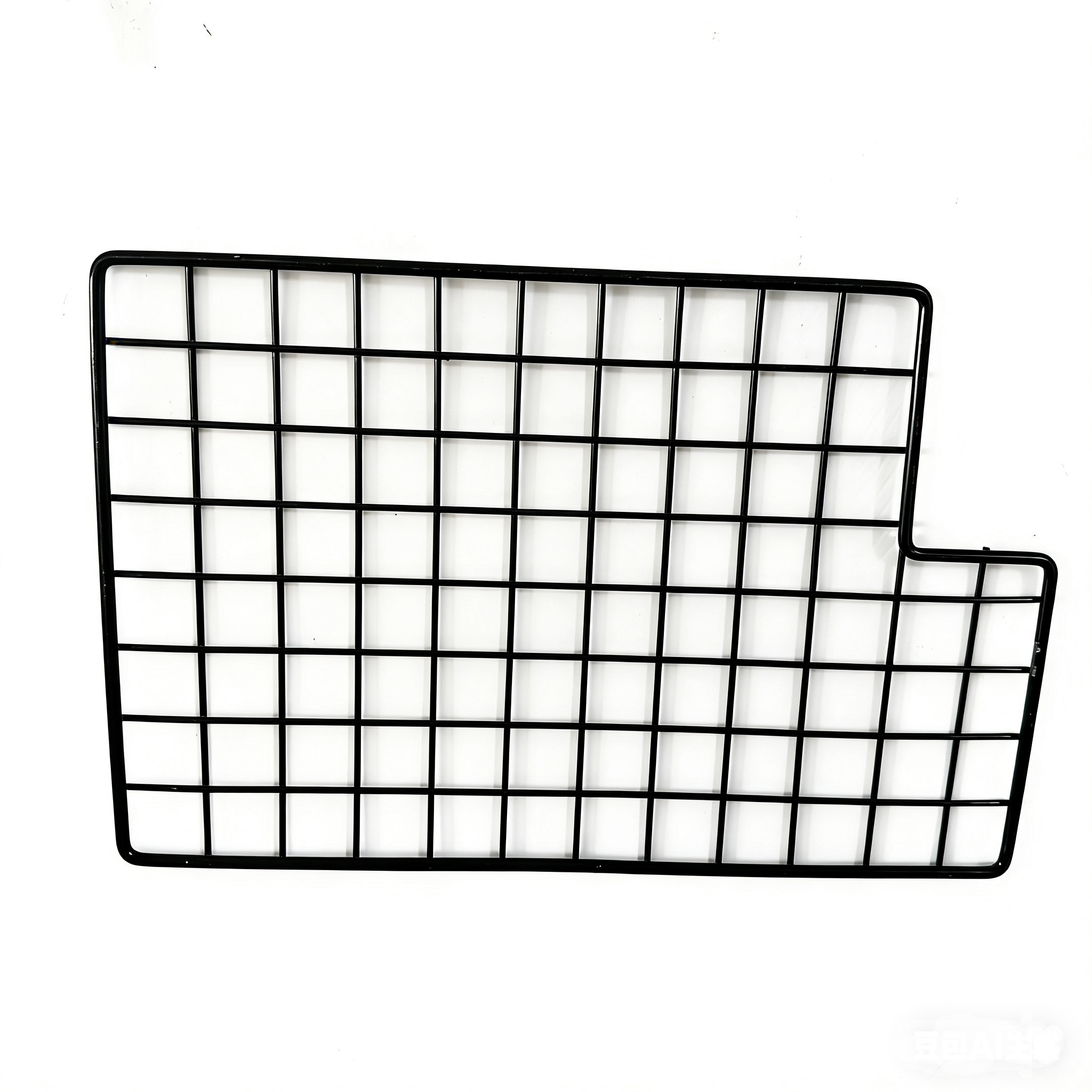

- Comprehensive Specifications & Customization: Supports diameter customization from 0.1mm to 10.0mm, covering fine wire (0.1mm-0.5mm) for electronics, medium wire (0.6mm-2.5mm) for general use, and thick wire (2.6mm-10.0mm) for heavy-duty applications. The wire can be supplied in coils (1kg-50kg/coil) or straight cut lengths (50mm-2000mm). Surface finishes include bright, matte, and polished (Ra ≤0.2μm for precision applications) 26.

- Flexible Packaging & Labeling: Packaging options include moisture-proof vacuum bags, cartons, and pallets, ensuring product quality during long-distance transportation. Labels are available in 5+ languages (English, Spanish, Portuguese, Arabic, French) with clear grade, specification, and safety information. Brand logo printing and OEM/ODM services are supported89.

🏭 Core Manufacturing Process & Professional Surface Treatment

The excellent performance of our stainless steel wire relies on sophisticated core manufacturing processes and professional surface treatment technologies. We strictly control every link from raw material melting to finished product surface finishing, ensuring that each batch of wire meets global quality standards and adapts to diverse application scenarios:

1. Core Manufacturing Processes: Precision Control from Melting to Drawing

- Vacuum Melting & High-Purity Billet Preparation: We adopt vacuum induction melting technology for high-purity stainless steel raw materials (chromium, nickel, iron, etc.). This process effectively avoids oxidation and impurity contamination during melting, ensuring the chemical composition of the molten steel is uniform and stable. The molten steel is then cast into billets through precision casting, and the billets are hot-rolled into wire rods with uniform diameter (error ≤±0.1mm) and dense internal structure, laying a solid foundation for subsequent drawing processing 47.

- Multi-Pass Precision Cold Drawing & Intermediate Annealing: The hot-rolled wire rods are subjected to multi-pass cold drawing using diamond dies (6-10 passes according to diameter requirements). Each pass of drawing is controlled by an intelligent computer system to ensure the wire diameter accuracy reaches ≤±0.01mm and the surface is smooth without burrs. Between drawing passes, intermediate annealing treatment is performed (1050-1150℃ for austenitic stainless steel such as 304/316L) in a protective atmosphere. This step eliminates internal stress generated during drawing, improves the ductility of the wire, and adjusts the mechanical properties to meet different strength requirements (soft, half-hard, full-hard) 26.

- Precision Cutting & Finishing Calibration: After drawing, the wire is cut into fixed-length straight wires (50mm-2000mm, length error ≤±0.1mm) by automatic precision cutting equipment or coiled into coils (1kg-50kg/coil) by an intelligent coiling machine. For high-precision application scenarios, additional finishing calibration is performed to ensure the straightness of the wire (straightness error ≤0.5mm/m) and the uniformity of the coil tension 68.

2. Professional Surface Treatment: Enhancing Corrosion Resistance & Aesthetics

3. Strict Quality Control for Manufacturing & Surface Treatment

- In-Process Inspection for Manufacturing: During the melting process, real-time monitoring of the chemical composition of molten steel is performed using a spectrometer; during drawing, the wire diameter is inspected every 30 minutes using a micrometer; the annealing temperature and time are strictly recorded and controlled to ensure consistent mechanical properties of the wire 68.

- Pickling & Derusting: Cleaning Surface Oxide Scale: The drawn wire first undergoes pickling treatment using a mixed acid solution (nitric acid + hydrofluoric acid) that is environmentally friendly and meets EU RoHS standards. This process effectively removes oxide scale, rust, and oil stains on the wire surface, ensuring the subsequent surface treatment effect. After pickling, the wire is rinsed with high-purity water multiple times to avoid acid residue 58.

- Passivation Treatment: Forming Protective Oxide Film: All stainless steel wires are subjected to professional passivation treatment, using either nitric acid or citric acid solution (selectable according to customer needs). Under controlled temperature and time conditions, a dense, uniform, and firmly bonded oxide film is formed on the wire surface. This film significantly enhances the corrosion resistance of the wire, enabling 304 grade to withstand 2000+ hours of salt spray corrosion (ASTM B117 standard) and 316L grade to withstand 3000+ hours 46.

- Optional Surface Finishing: Meeting Diverse Aesthetic & Precision Needs: According to application scenarios, we provide three surface finish options: ① Bright Finish: Achieved by polishing with a precision polishing wheel, the surface is bright and reflective, suitable for architectural decoration and handicrafts; ② Matte Finish: Obtained by sandblasting or chemical matting, the surface is smooth without glare, suitable for food processing equipment; ③ Precision Polishing: For high-precision scenarios such as medical equipment, the surface roughness Ra ≤0.2μm, ensuring hygiene and easy cleaning 27.

- Drying & Anti-Rust Protection: After surface treatment, the wire is dried in a constant-temperature oven (120-150℃) to ensure surface dryness. For coil products, a thin layer of food-grade anti-rust oil (optional) is applied to further protect the surface during storage and transportation 89.

- Surface Quality & Performance Testing: After surface treatment, the wire surface is inspected for defects such as scratches, pits, and uneven passivation film using a magnifying glass and a surface roughness tester. Corrosion resistance testing (salt spray test, ASTM B117) is performed on finished products to ensure the passivation effect. A 1% random sampling method is adopted for each batch, and only products that pass all tests are allowed to leave the factory 9.

🌍 Global Application Scenarios: Covering High-Demand Industries

Our stainless steel wire is widely used in global high-demand industries, providing reliable solutions for demanding applications:

🏥 Medical & Pharmaceutical

- Medical Equipment Manufacturing: Fine 316L stainless steel wire for European and North American medical device components (surgical instruments, orthopedic implants, catheters). The high corrosion resistance, biocompatibility, and hygiene meet medical grade requirements (ISO 13485) 79.

- Pharmaceutical Packaging: Medium 304 stainless steel wire for Asian and European pharmaceutical packaging (capsule filling machines, tablet presses). The hygienic surface avoids contamination of pharmaceutical products 35.

🍎 Food & Beverage

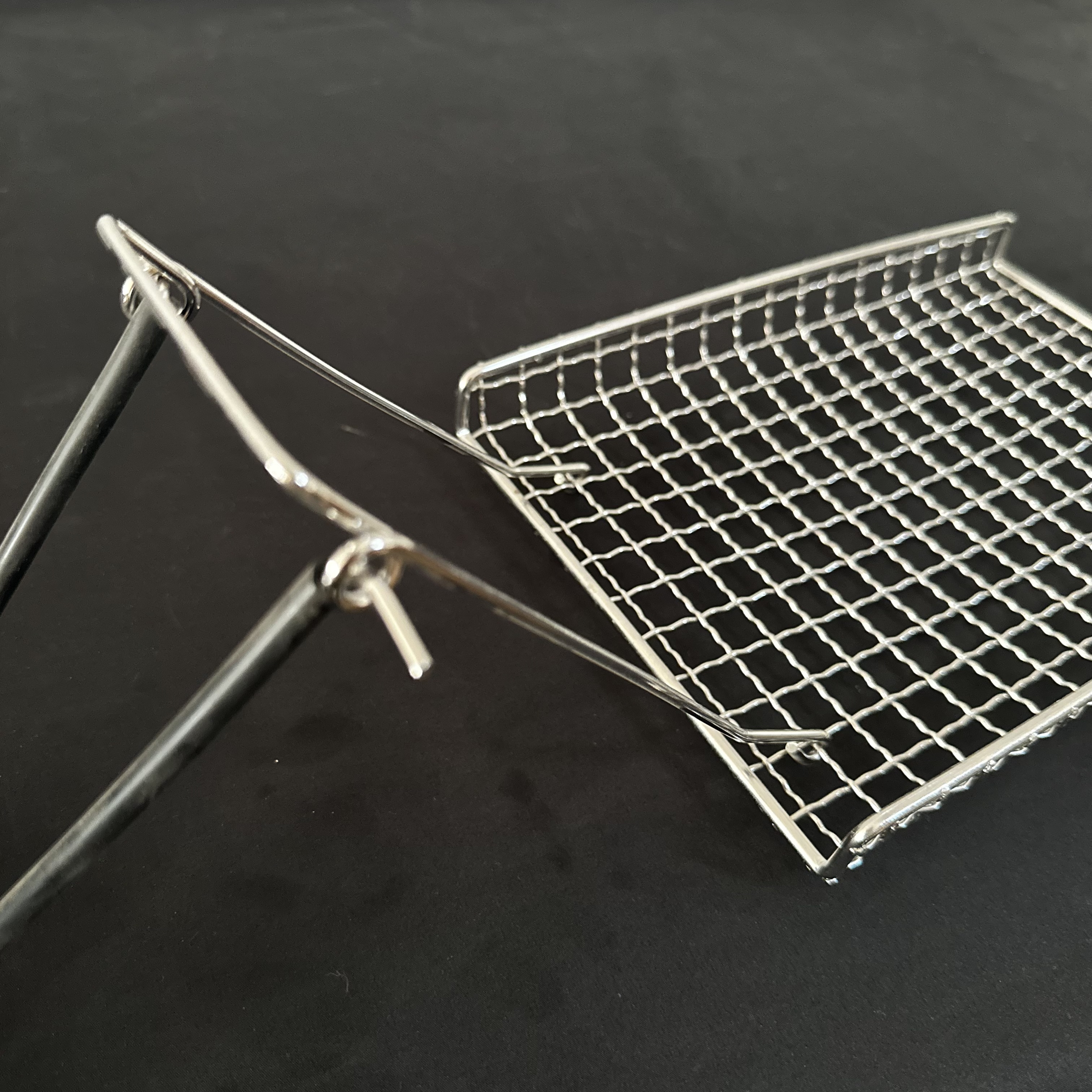

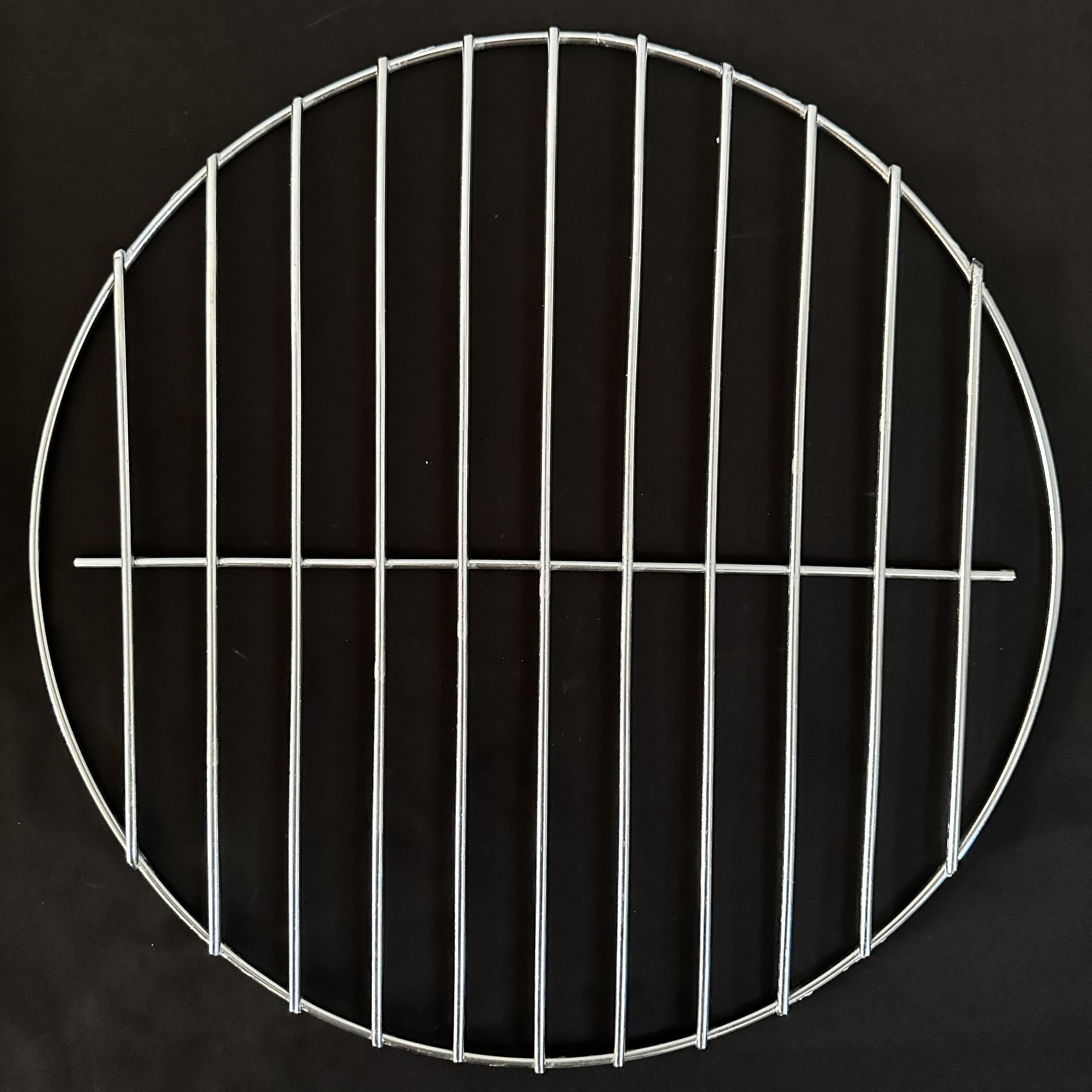

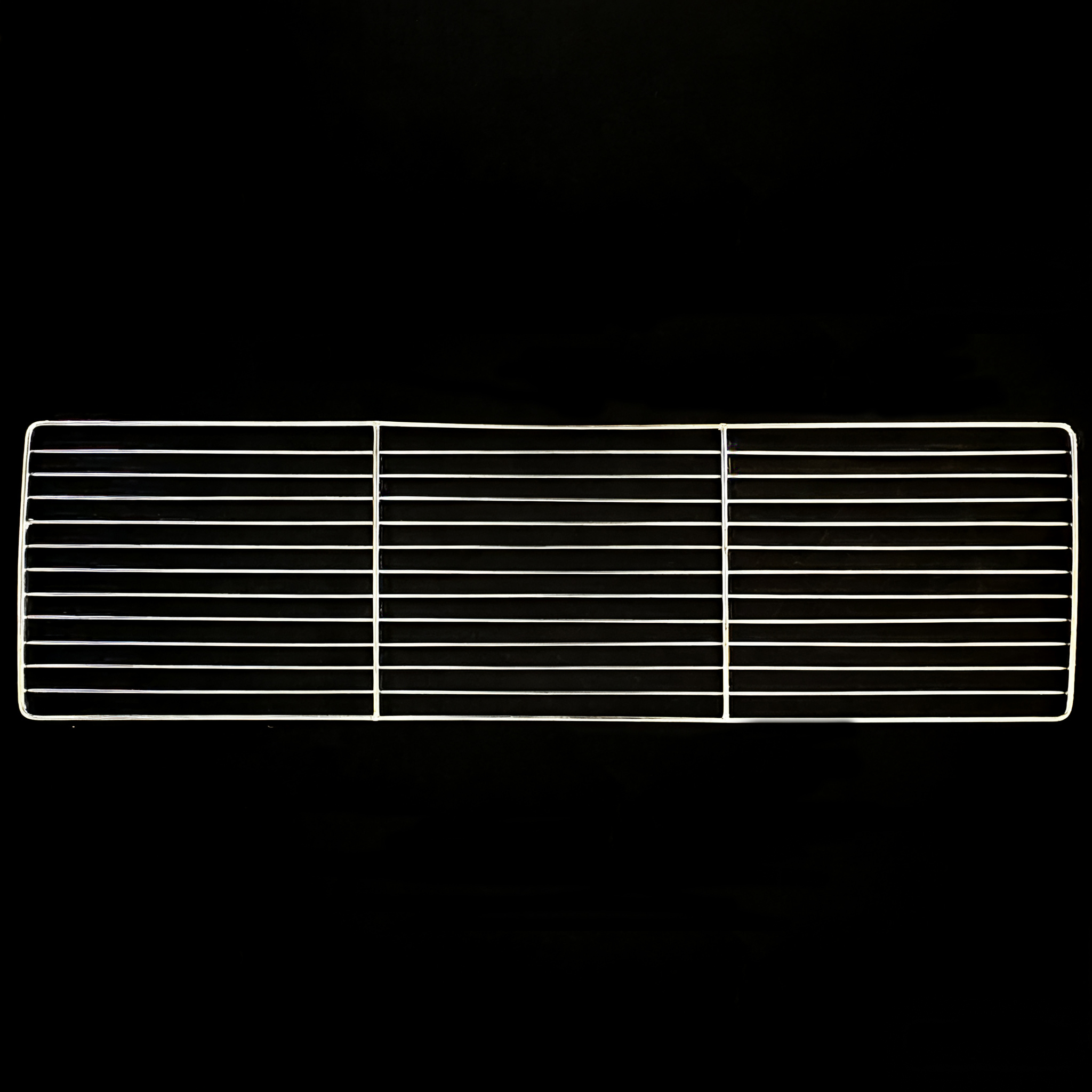

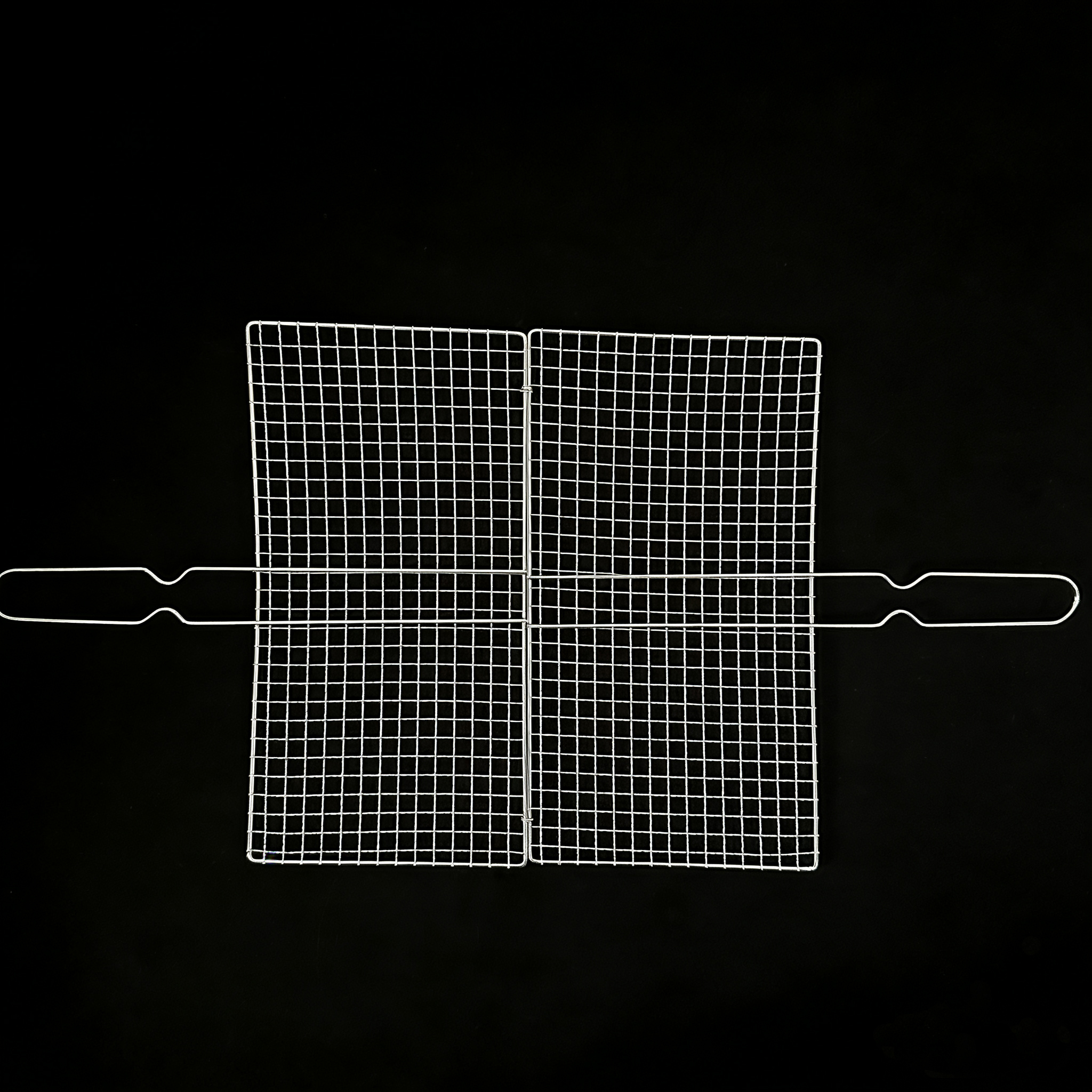

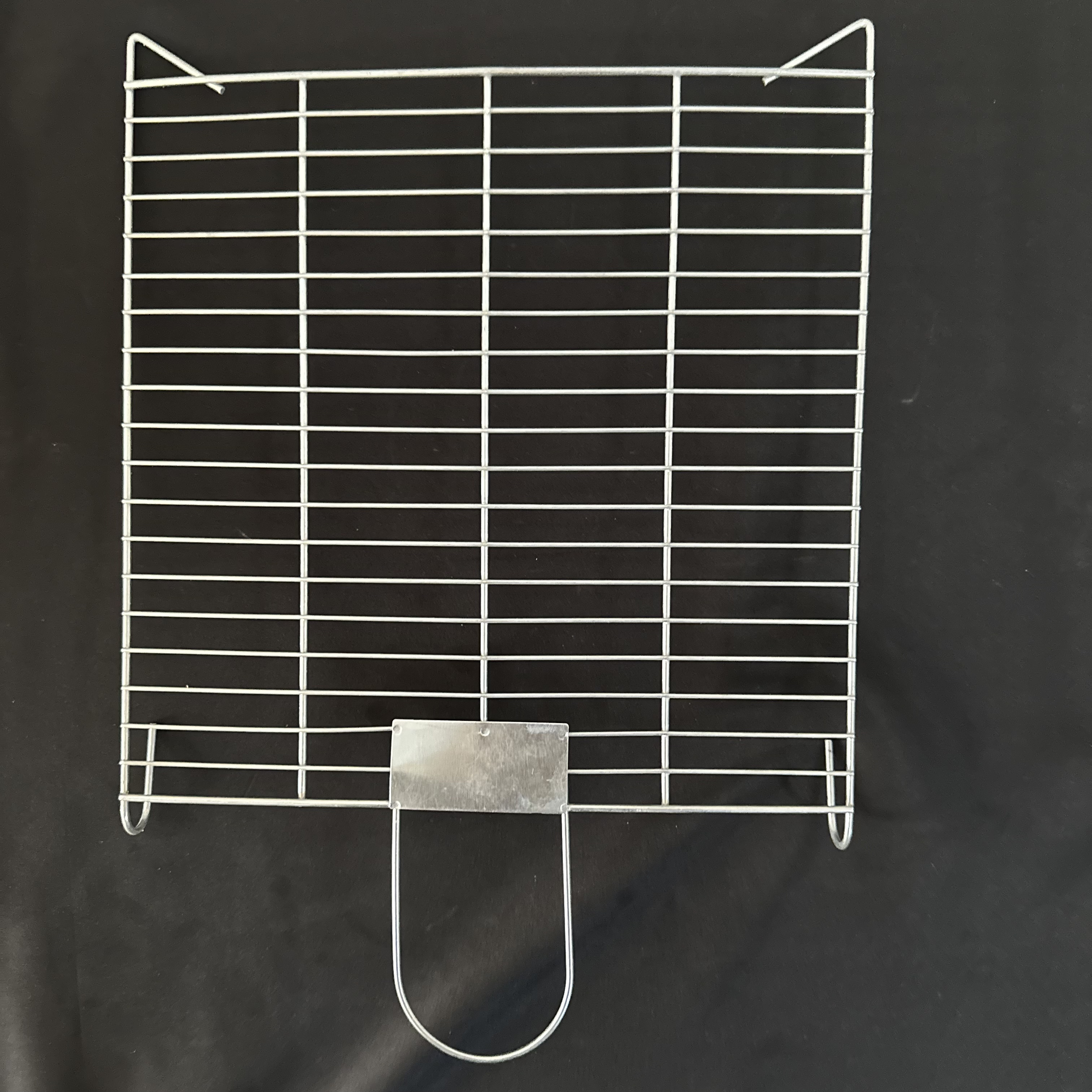

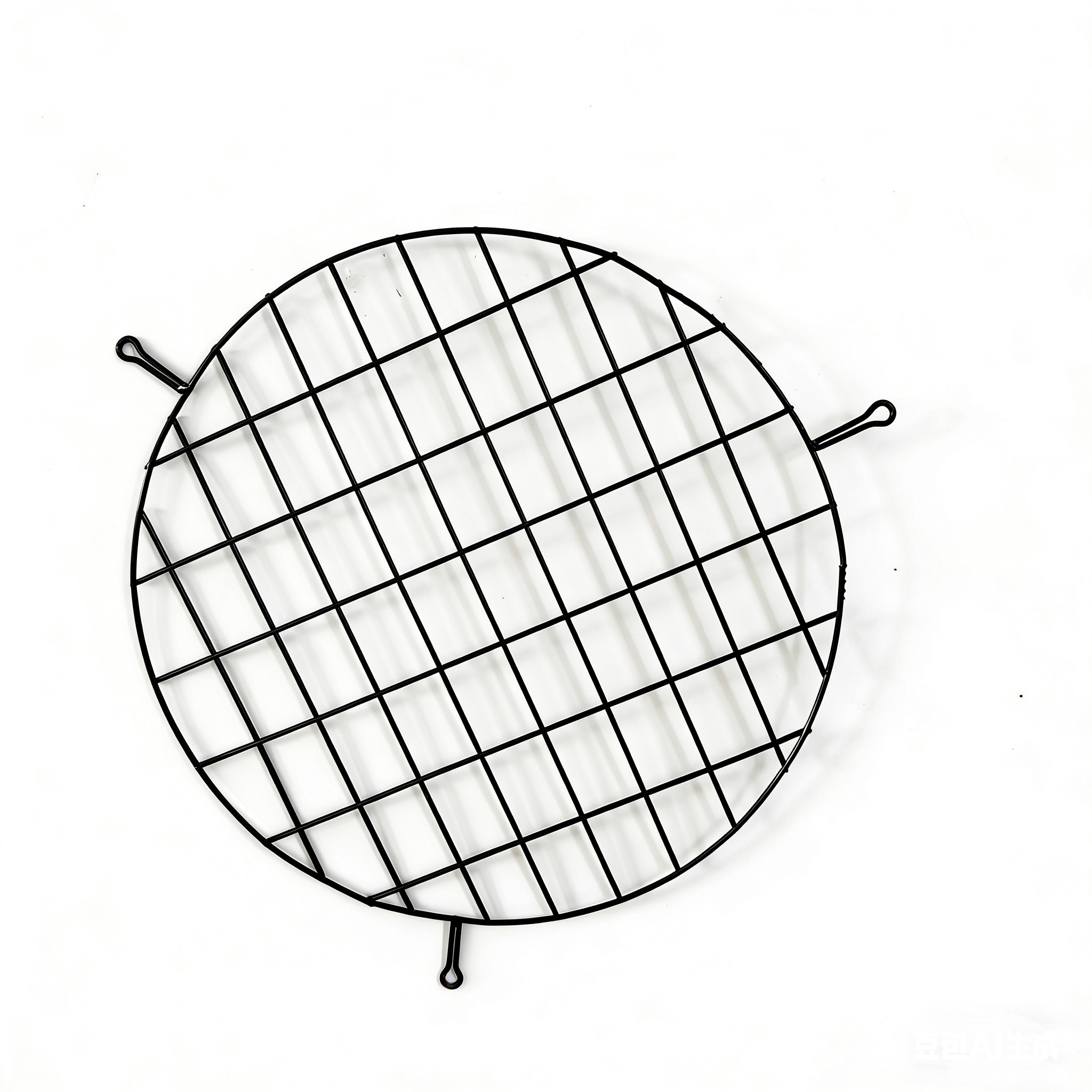

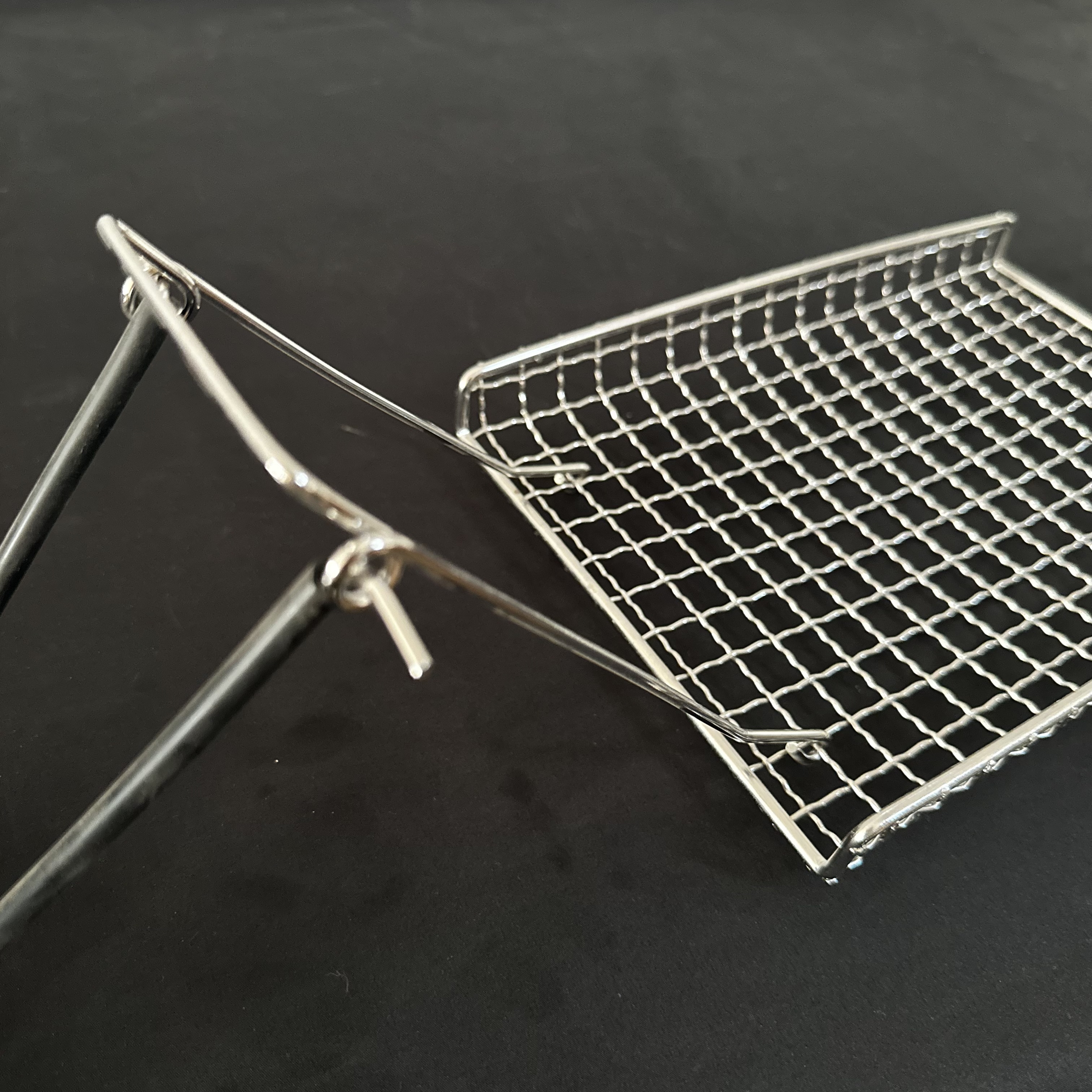

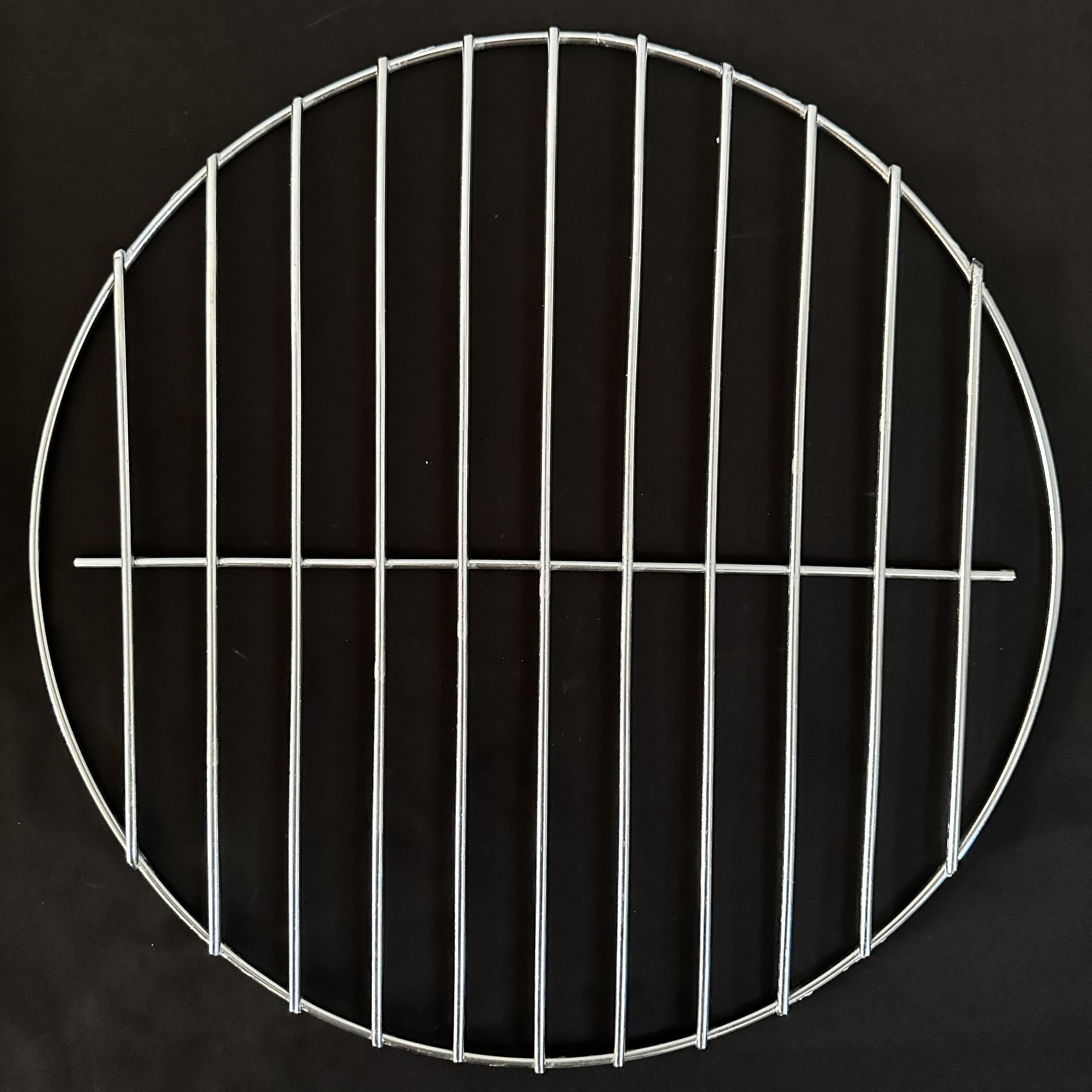

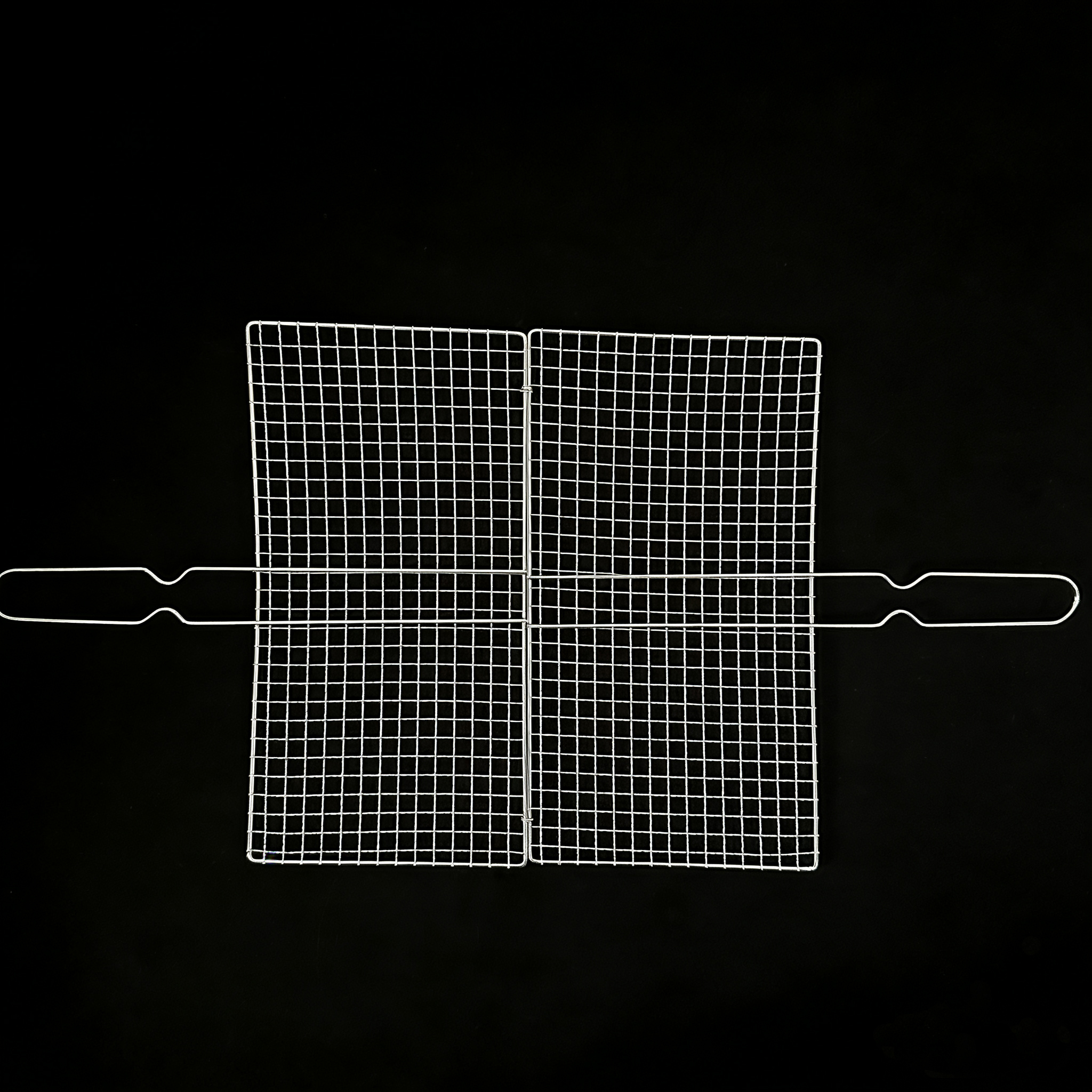

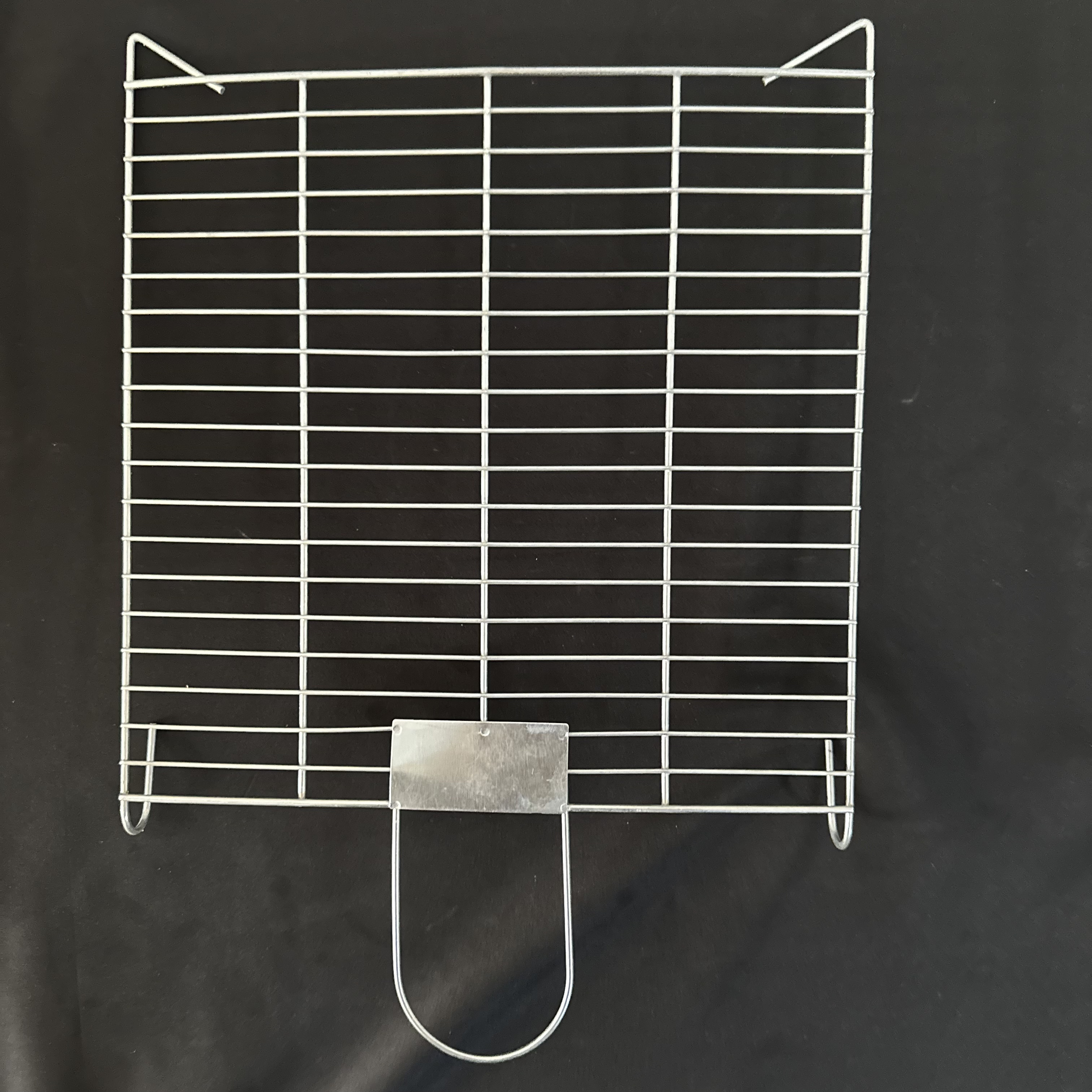

- Food Processing Equipment: Medium 304/316 stainless steel wire for global food processing machines (conveyor belts, sieves, mixers). The corrosion resistance resists food acids, salts, and cleaning agents, complying with EU FDA and US NSF standards 78.

- Food Packaging & Tying: Fine 304 stainless steel wire for European and North American food packaging (fruit bundling, sausage casings). The non-toxic, smooth surface avoids damaging food and ensures safety 59.

🏭 Chemical & Marine

- Chemical Industry: Thick 316/316L stainless steel wire for Southeast Asian and Middle Eastern chemical plants (reaction vessel reinforcement, chemical filters). The corrosion resistance resists strong acids, alkalis, and organic solvents 24.

- Marine & Coastal Engineering: Thick 316L stainless steel wire for North American and European marine equipment (ship rigging, offshore platforms, coastal fencing). The chloride ion resistance avoids corrosion in saltwater environments 68.

🏗️ Construction & Infrastructure

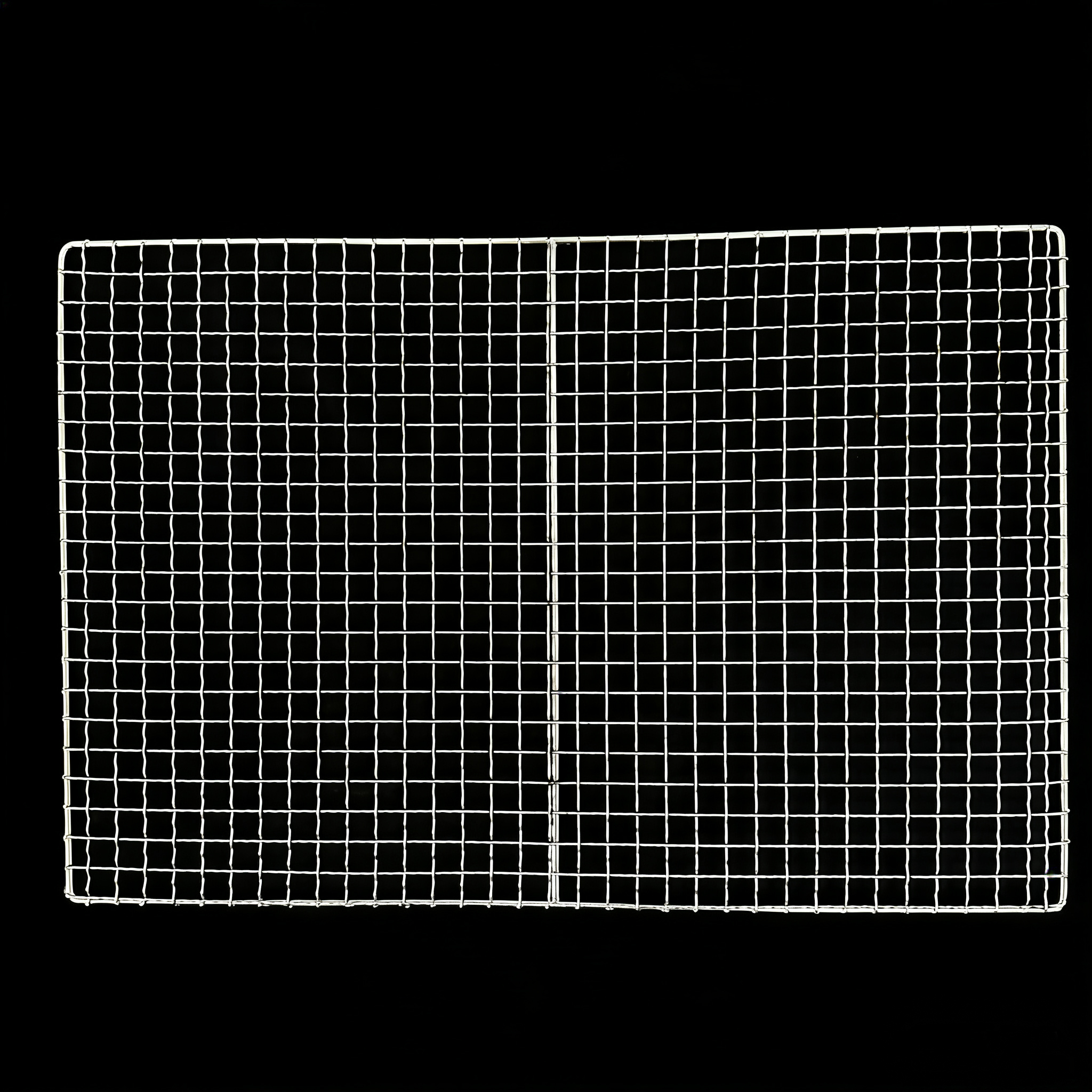

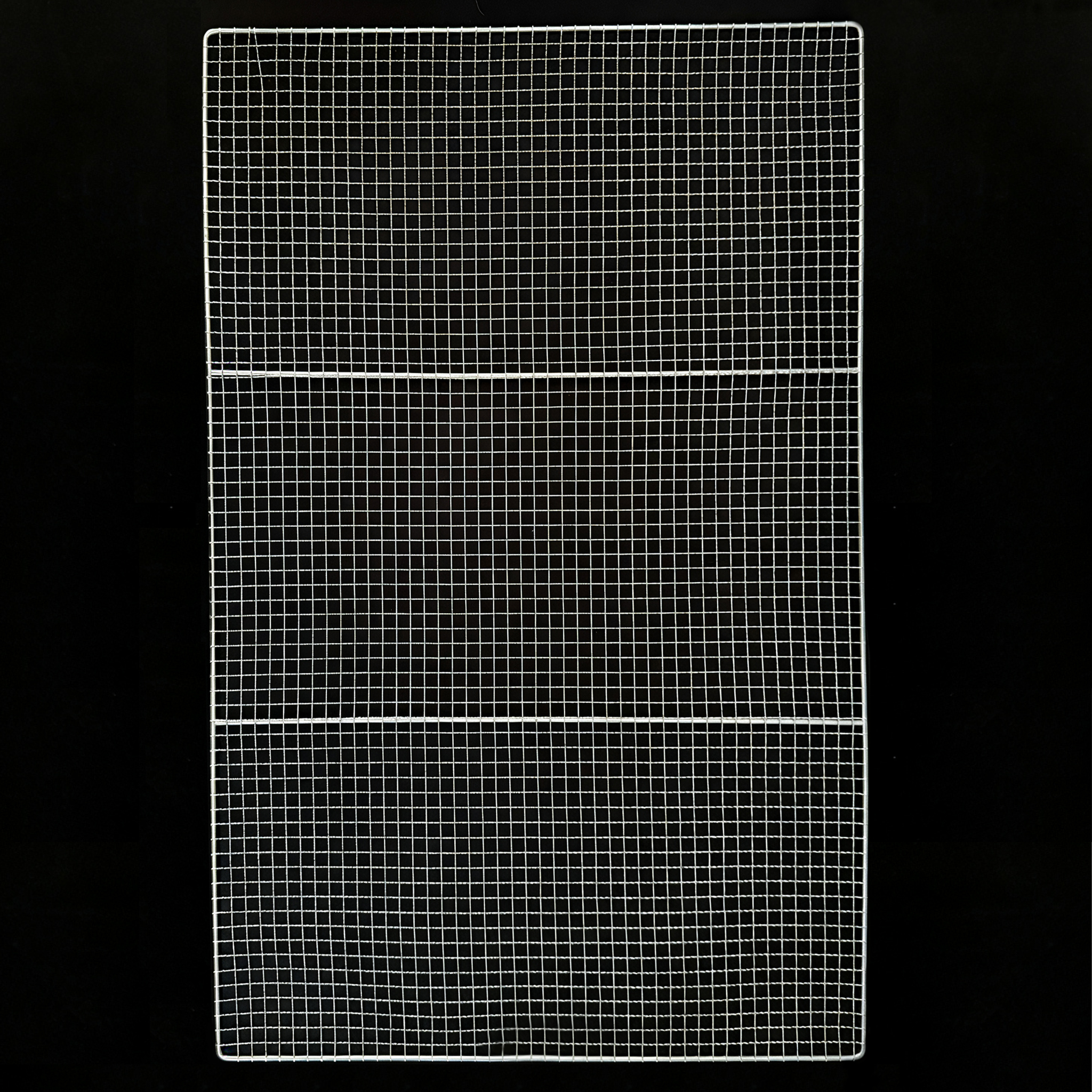

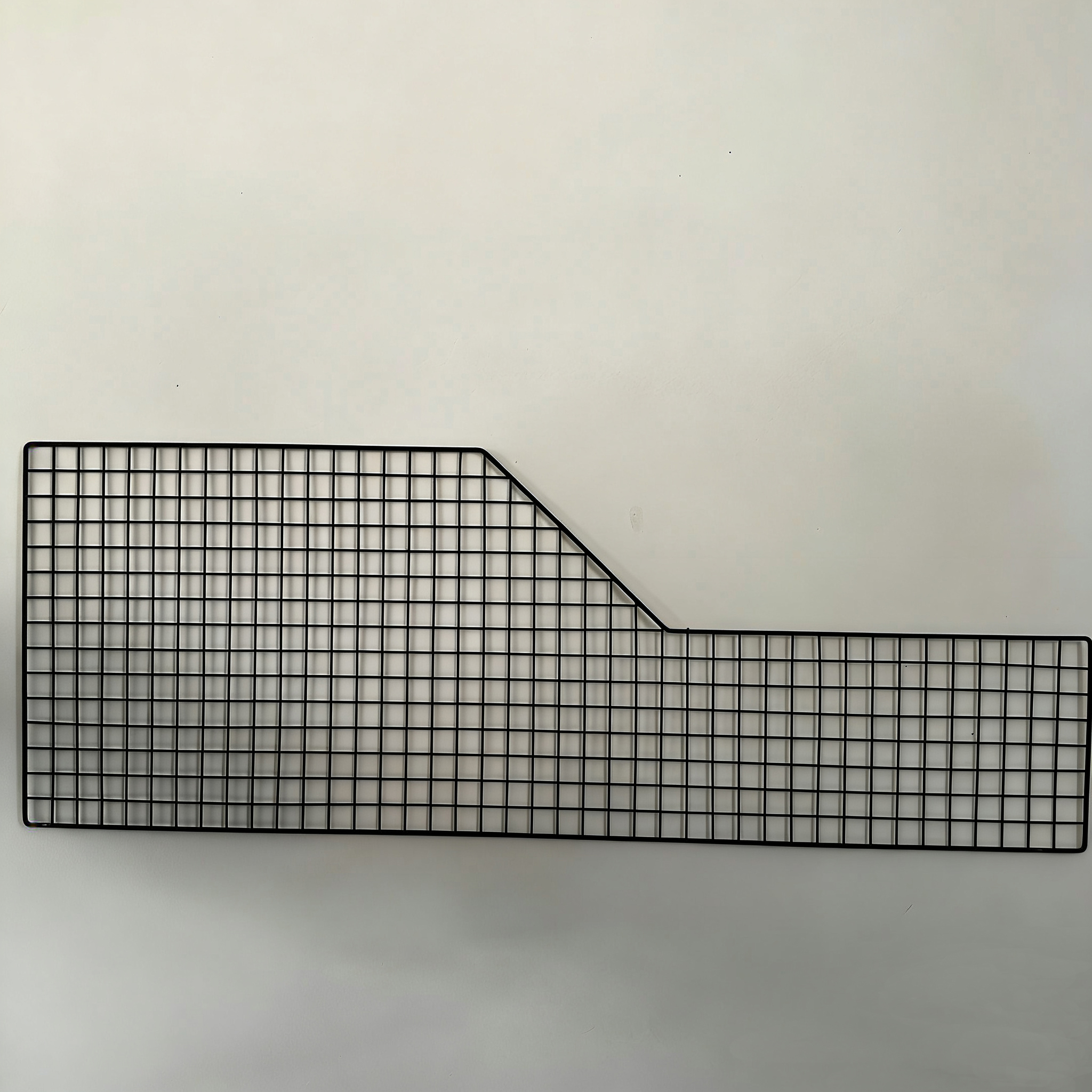

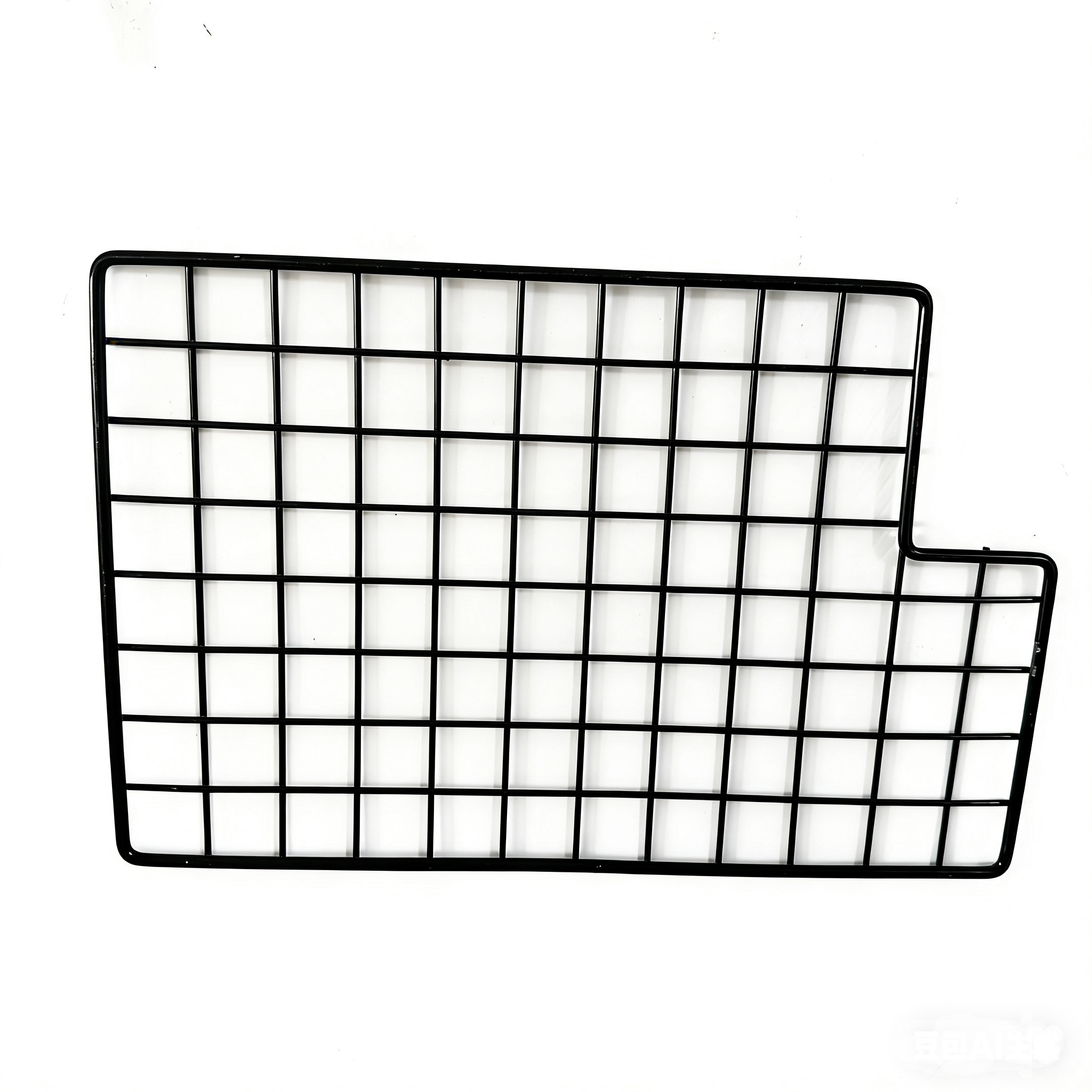

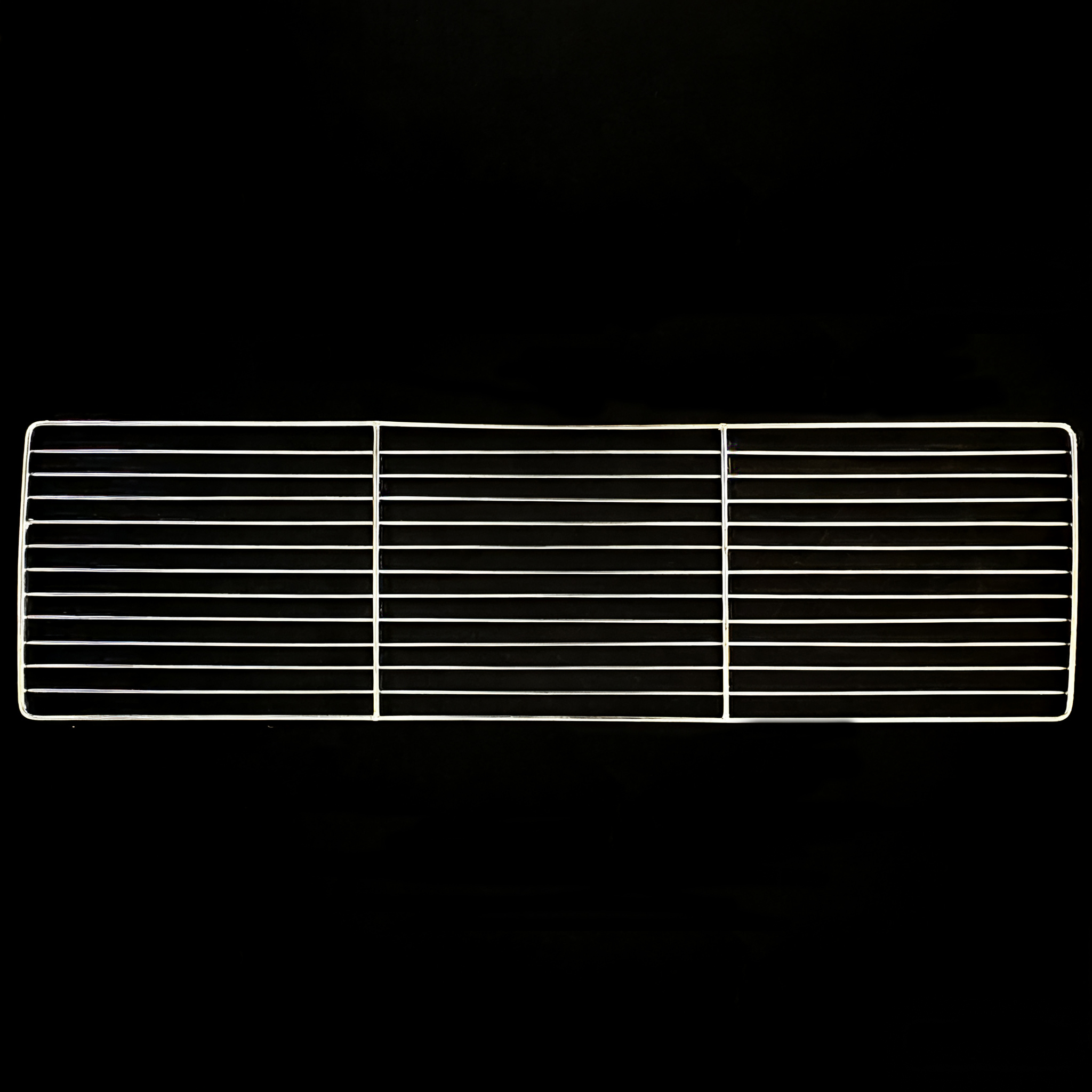

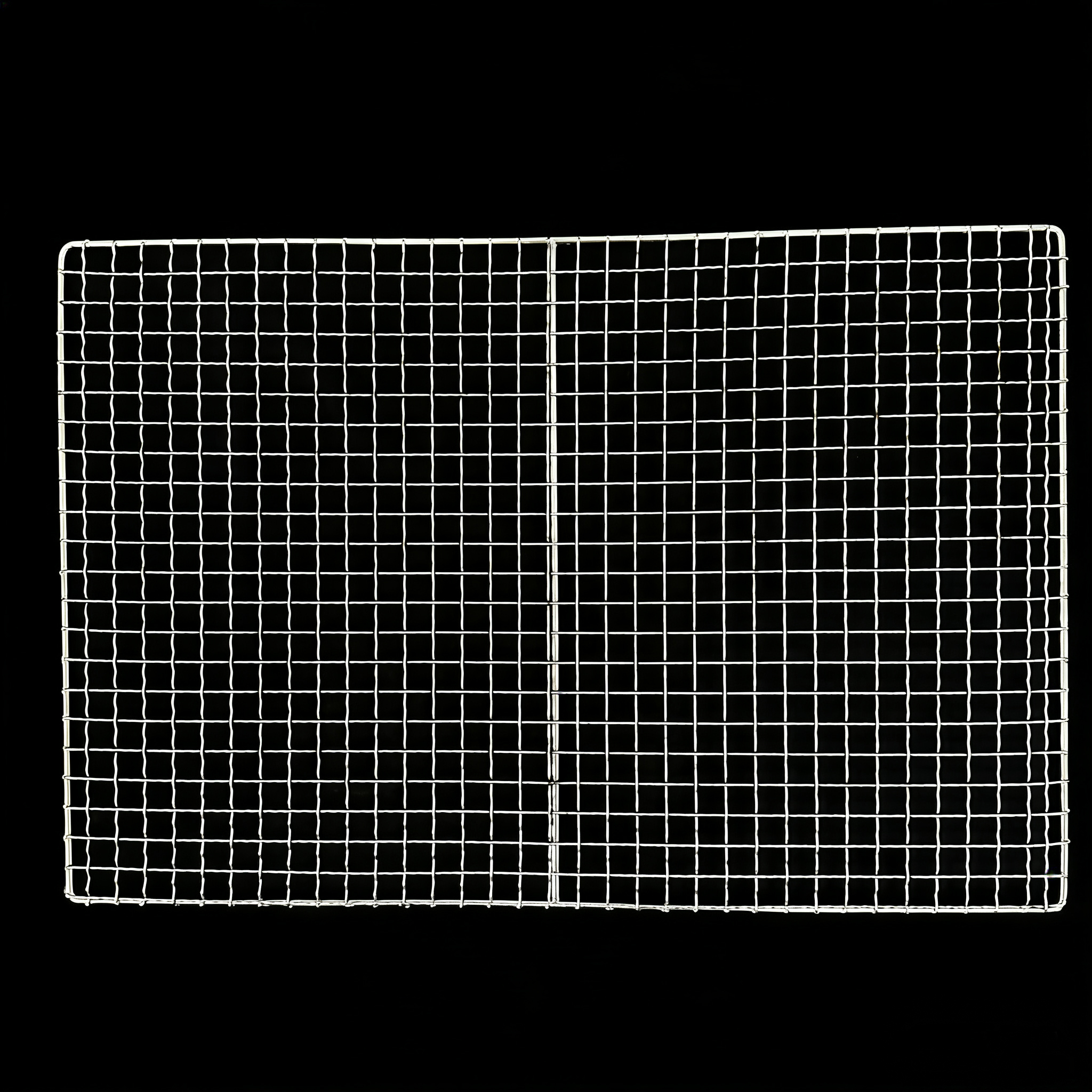

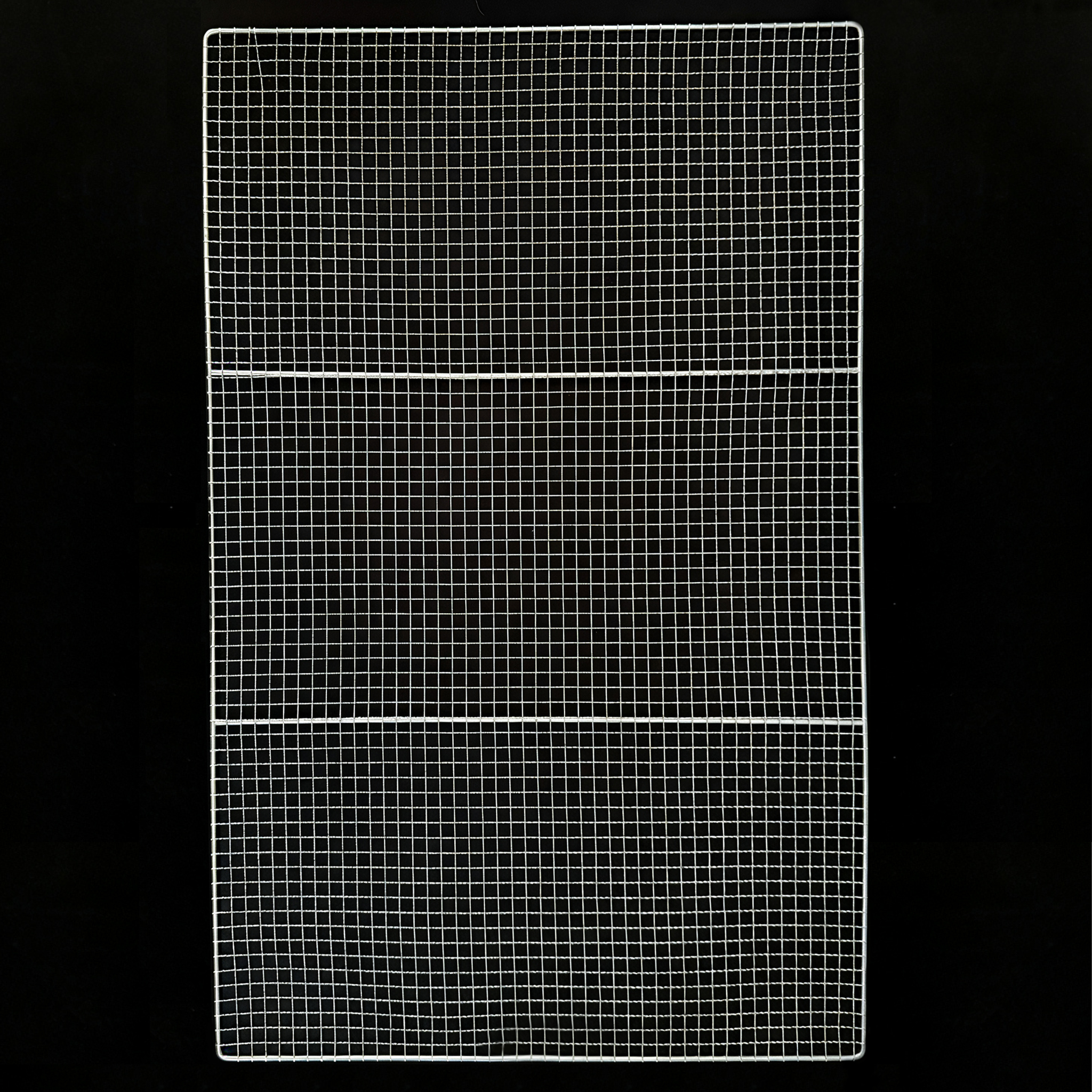

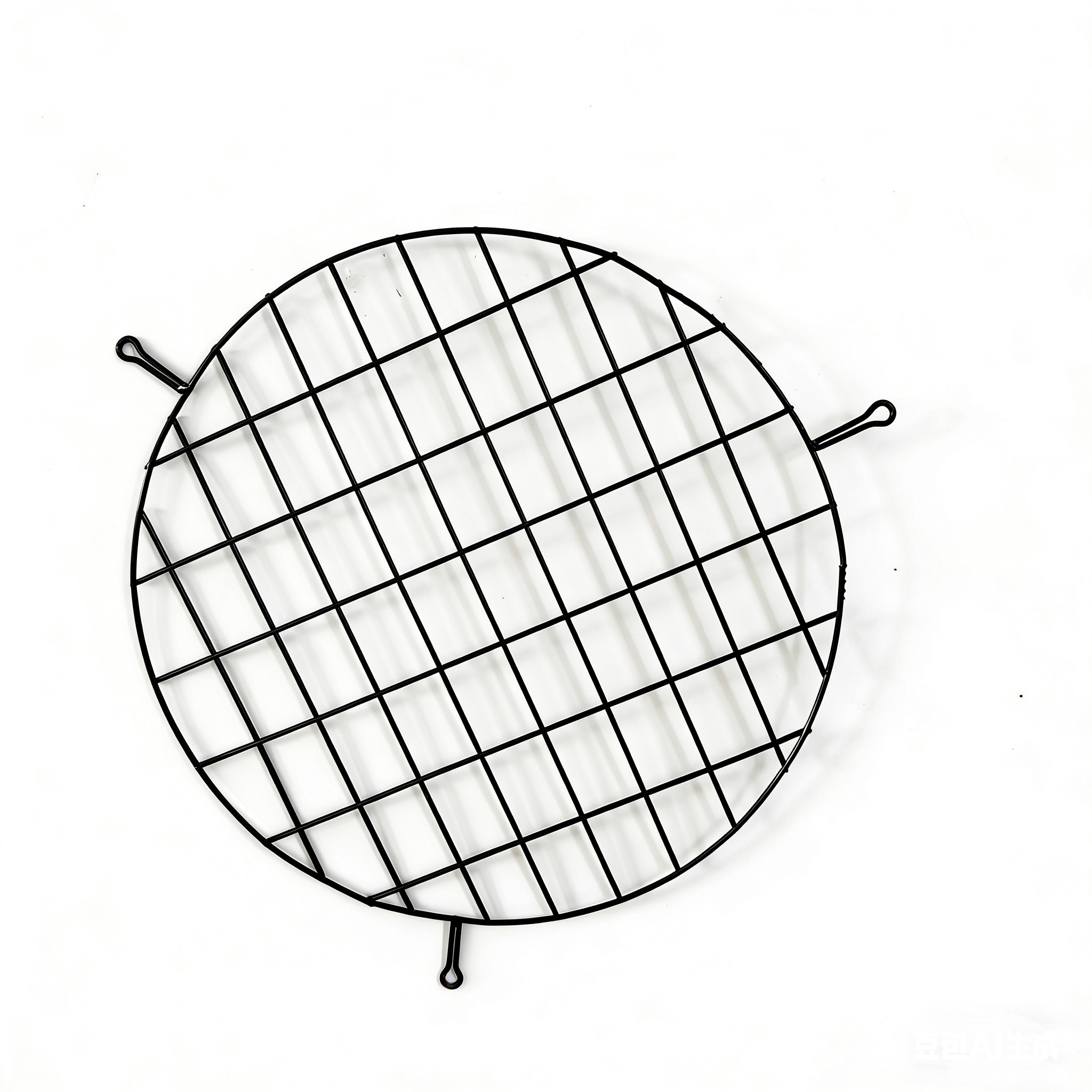

- Architectural Decoration: Medium 304 stainless steel wire for European and Asian architectural decoration (glass curtain walls, handrails, decorative meshes). The bright surface and corrosion resistance ensure long-term aesthetic appearance 12.

- Reinforcement & Fencing: Thick 304/430 stainless steel wire for African and South American construction reinforcement and fencing. The durability resists outdoor weathering 46.

🔌 Electronics & Automotive

- Electronic Components: Fine 304 stainless steel wire for Asian and European electronic components (batteries, sensors, connectors). The high precision and stable performance ensure the reliability of electronic products 79.

- Automotive Industry: Medium 304/316 stainless steel wire for global automotive components (fuel injection systems, exhaust pipes, springs). The high temperature and corrosion resistance adapt to automotive working environments 48.

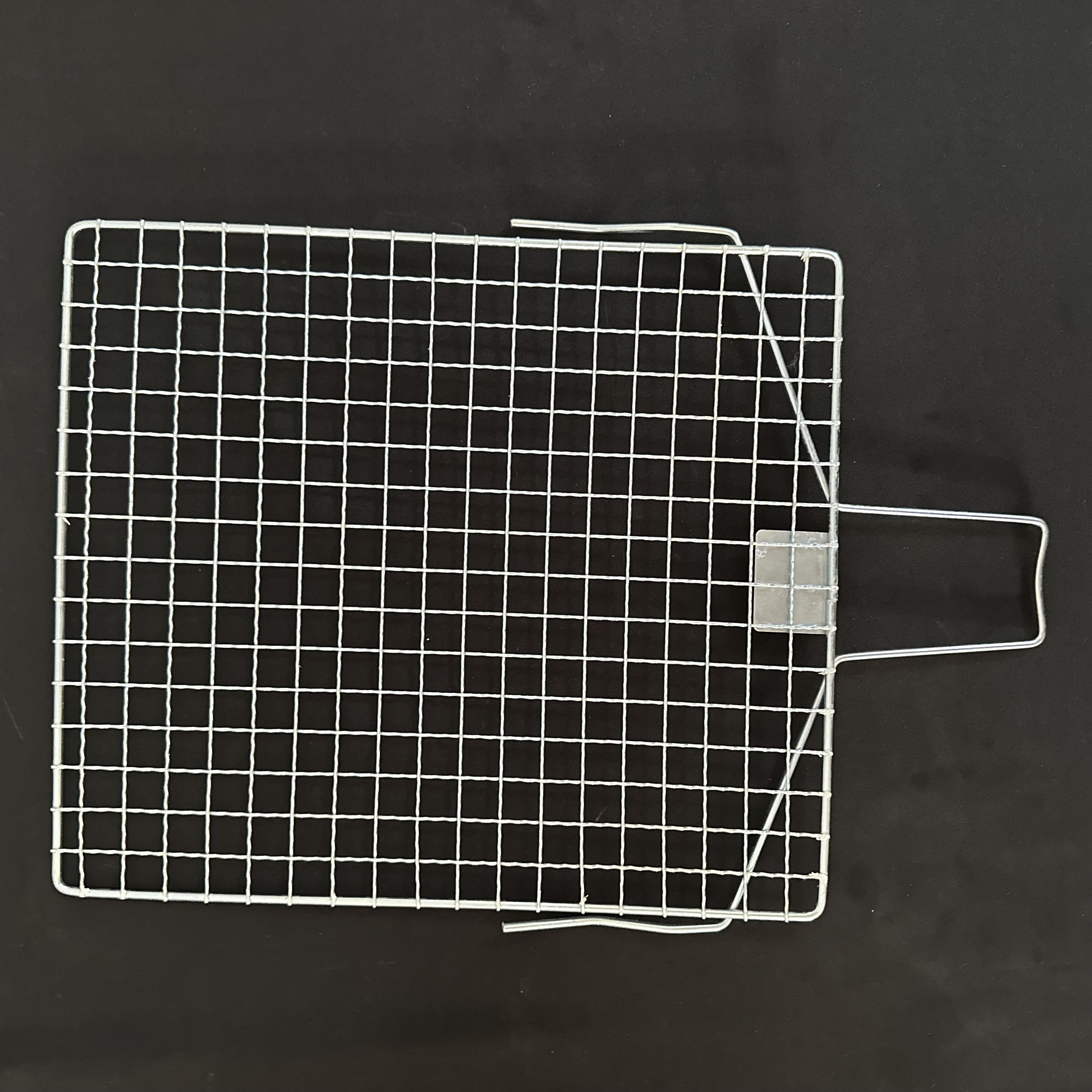

🎨 Handicrafts & Daily Necessities

- Handicraft Making: Fine colored or polished stainless steel wire for European and Asian handicrafts (jewelry, wire sculptures, Christmas decorations). The smooth surface and ductility facilitate shaping 12.

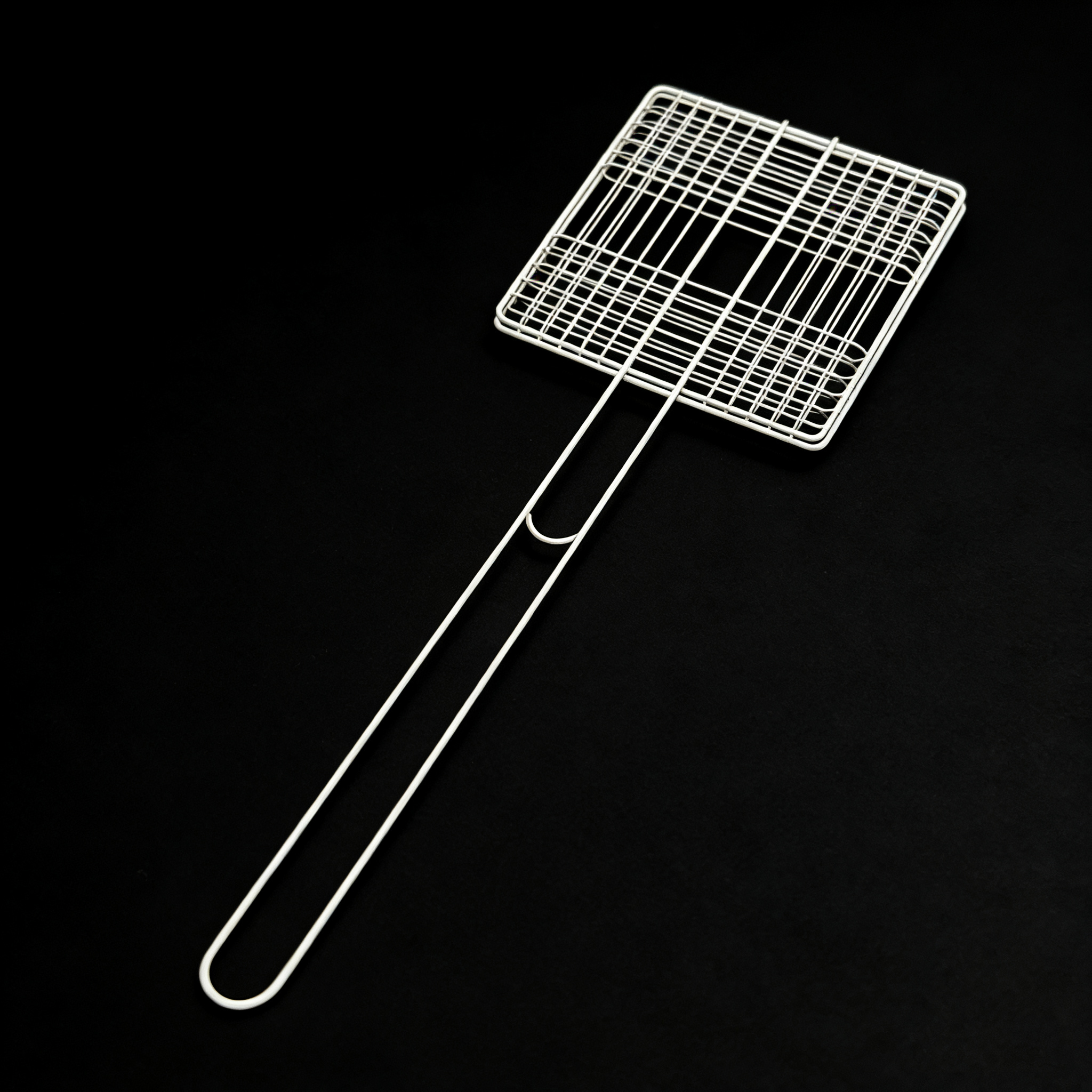

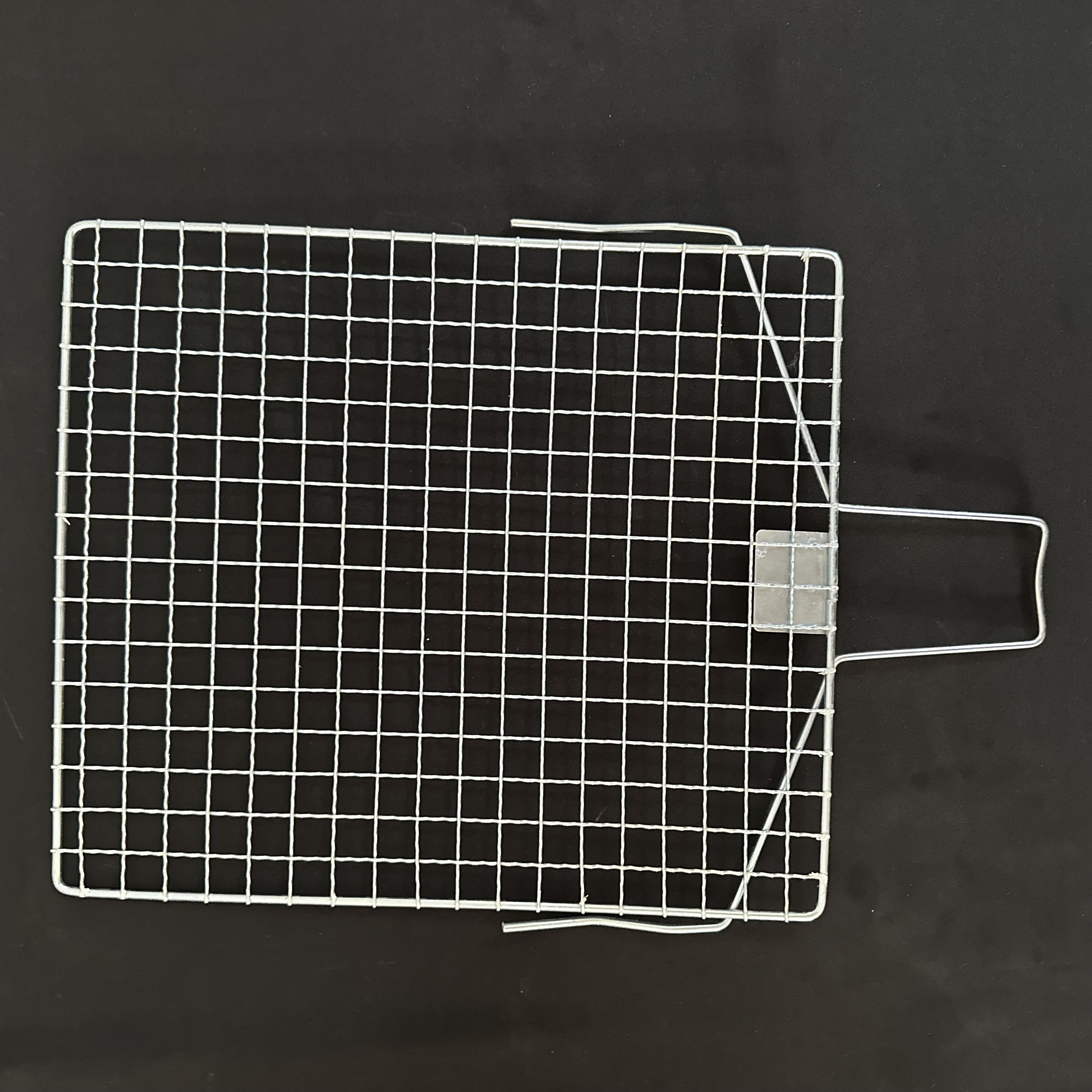

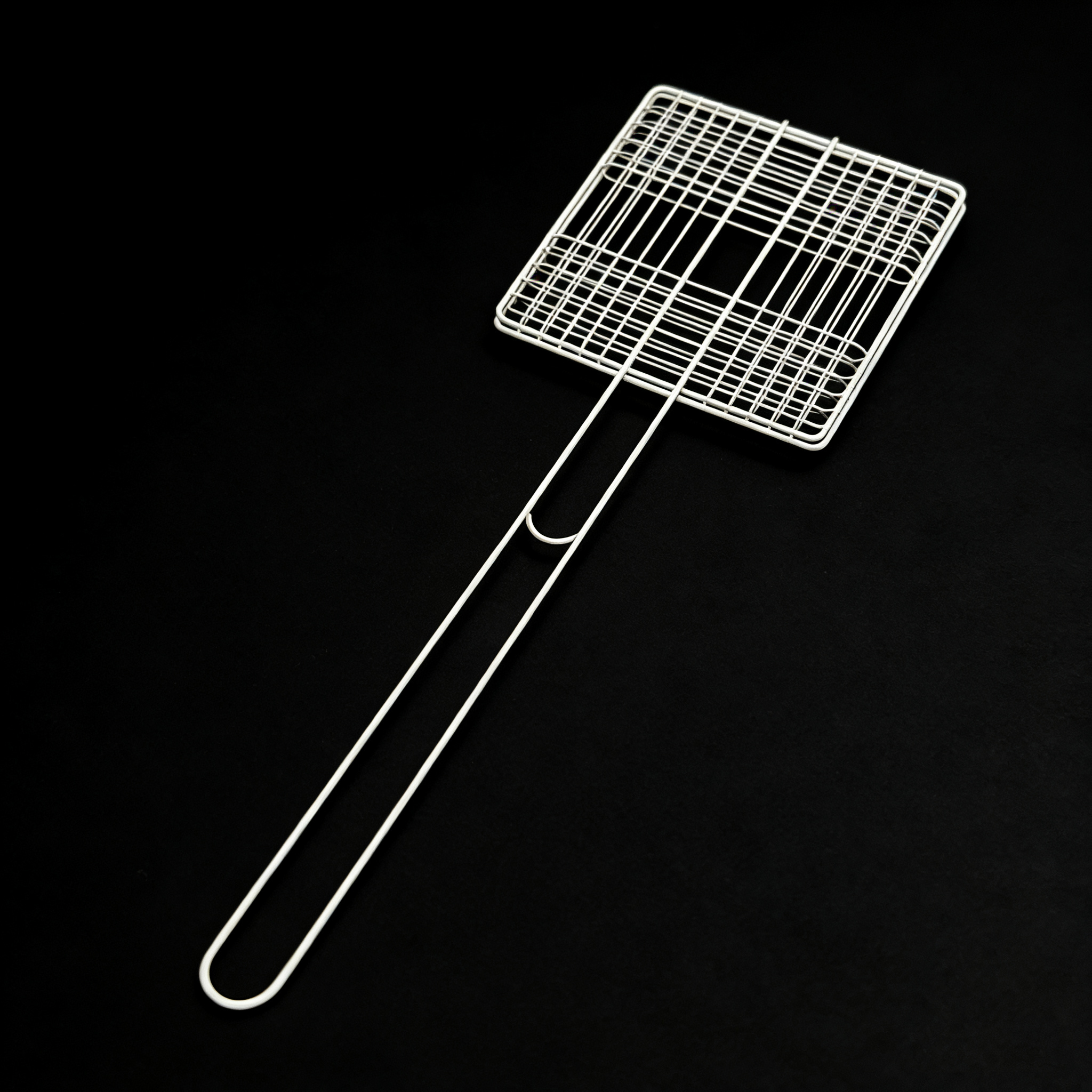

- Daily Necessities: Medium 304 stainless steel wire for global daily necessities (kitchenware, clothes hangers, pet cages). The hygiene and corrosion resistance meet daily use needs 36.

🌍 Your Trusted Global Stainless Steel Wire Partner

We understand the complexities of global trade and the high requirements of stainless steel wire in demanding industries. We provide comprehensive support to ensure smooth cooperation:

- Global Standard Compliance: Passes ISO 9001, ISO 13485 (medical grade), EU EN 10088, US ASTM A498, and FDA/NSF standards. Provides complete SGS/Intertek test reports (chemical composition, corrosion resistance, tensile strength) for hassle-free customs clearance in 120+ countries 39.

- Full Customization Service: Tailor stainless steel grade, diameter, length, surface finish, packaging, and labeling to regional needs. Support OEM/ODM with branded packaging and multilingual product manuals to help you build local brand loyalty.

- Flexible Cooperation Terms: Accept small trial orders (10kg for coils, 500pcs for straight cut) for new partners; bulk orders enjoy tiered pricing discounts. Short production lead time: 7-15 days for standard orders, 15-25 days for custom orders.

- Efficient Logistics & Multilingual Support: Strategic warehouses in China, Europe, and the USA enable fast delivery (3-7 days for key markets). Provide 24/7 after-sales service in 5+ languages to solve your problems anytime, including technical consultation and order tracking.

📞 Get Your Custom Stainless Steel Wire Solution Today

Whether you’re a medical equipment manufacturer in Europe, a food processor in North America, a chemical plant in Southeast Asia, or an architectural firm in Africa, we have the perfect stainless steel wire to meet your local demanding needs. Send your inquiry now to get free samples, a customized quote, and detailed product specifications. Let’s work together to create reliable and high-performance solutions!